An AC motor can function as a brake for unwinding applications

For coil unwinding machinery, precise brake control based on an AC motor provides a quantum leap improvement in performance, as well as operating, maintenance and cost benefits. Replacing a traditional mechanical brake-and-air-supply system eliminates mechanical headaches and provides better control.

|

View more like this on PlantServices.com |

The mechanical brake functions like the brake in your car: both have a disk, calipers and friction pads. The brake's function is to hold a constant tension on the unwinding spool to avoid variations in print registration, wrinkled laminated materials, uneven glue application, film stretching, and inaccurate wire drawing, to name just the most critical functions.

A load cell monitors web tension and a setpoint controller feeds the difference between the desired unwind tension and the tension measured by the load cell to the air-brake control. Because both the tension system and the setpoint controller are electronic and the mechanical brake isn't, a current-to-air-pressure transducer must convert the 4-20 mA signal to a proportional air pressure. When the measured tension is too low, the brake's air supply increases, which applies greater braking force to increase web tension. The same thing happens when you put more pressure on your car's brake pedal.

This method has been used for decades, but as air brakes and air-supply systems age, they invariably become a maintenance headache.

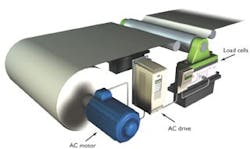

Figure 1. An integrated web speed and tension control that includes motor (left), drive (center) and load cell (right) applies easily to printing, coating, film, foil, flexographic, wire and cabling, and textile machines.

Electronic approach

In contrast, an electric motor produces the holdback force, functioning like a car's alternator, which produces electrical voltage and current as long as the engine applies torque, or turning power, to its input shaft. Motors configured to act as generators or alternators exhibit mechanical resistance when the shaft is rotated. So configured, they act as brakes and require torque to turn the input shaft. As the excitation current increases, it takes more torque to turn the shaft, and more braking is the result.

The idea of using a motor as a brake is not new. In fact, it has already been used successfully in paper manufacturing, where the rolls are large, as well as in other large installations that require high horsepower. These applications feature a DC motor, gearbox and drive control that modulates the braking force. Because the motor generates power in the process, the energy must be drained off by feeding it back to the plant, or by heating resistor banks. Returning energy to the plant yields a payback, but the approach is generally used only on motor brakes larger than 25 hp.

Using VFDs and motors

Historically, cost has been the greatest obstacle to using a motor as a brake on a small-horsepower unwinder application. However, variable frequency AC drive (VFD) technology provides a way around this limitation and offers better performance and control than the traditional DC unit.

Small-horsepower AC motors are widely available at a low cost-per-horsepower, which makes them competitive with mechanical brakes. They have a lower life cycle cost when compared to the cost of installing, operating and maintaining a mechanical brake-and-air-supply system.

Flux versus friction

Consider a two-roll unwinder with two mechanical air brakes that had a host of repeating problems. Brake pads wore out regularly, worn disks caused pulsating braking, and the air supply and I/P regulator required periodic maintenance. Low-tension control was poor, especially when the web was nearing the core, where the lowest braking torque is needed. Product quality and production suffered.

The unit was retrofitted with a five-horsepower AC four-pole motor, 4:1 gear reducer and a drive featuring built-in flux braking, which measures the motor torque and flux. The drive's clock rate of 40 kilohertz eliminates the need for tachometer feedback. The drive operates in torque mode, rather than speed mode.

The brake has to provide a torque equal to the desired web tension multiplied by the instantaneous roll radius. A 4-20 mA signal controls the motor torque and tension at any speed, including a dead stop. And, because the control loop response time is less than five milliseconds, it maintains optimal tension from zero speed through rapid acceleration, to steady-state speed and back down through rapid deceleration to a stop. The motor changes torque direction seamlessly to help maintain tension even during fast acceleration. For threading the machine, the brake motor can be sped up to provide enough slack web material to feed into the rollers.

Stable tension control also improves product quality. The motor, drive and load cell can be used for film, foil, flexographic, wire, cable and textile machines as well as for printing and coating.

The future

The market wants better braking solutions, and the use of small-horsepower, low-voltage AC motors and drives for that purpose will continue to be compelling for end users that maintain coil unwinders. Not long ago, machines used relay logic rather than programmable logic controllers, line shafts rather than direct-driven rolls, and mechanical dancers rather than electronic load cells for tension control. Motor brakes are a natural part of this evolution to more precise and electronic control.

Bob Sarnelli is product manager with ABB Inc., Automation Technologies, Web Tension Products. He can be reached at [email protected] and (845) 278-6841.