How to protect bearings and extend motor life

The electric motor is central to industrial process equipment. For example, plants may have a large pump population. Therefore, they likely have a large electric motor population driving those pumps. Some examples are.

- Bakeries blending cake mixes: The blenders and mixers are driven by electric motors.

- Mines using electric motors to drive fans, gearboxes, and crushing equipment, and even large-haul trucks.

- Power generation facilities producing electricity that drives motors: A substantial number of electric motors are used to get the job done.

Electric motors are everywhere, doing what they do best: turning electrical energy into mechanical energy.

Primarily dependable and efficient equipment

For the most part, modern electrical motors are pretty reliable. They have been around for years. Most days, personnel do not even think about the motors doing the work. Some motors are automatically monitored. However, most personnel walk over to the motor control center, and without thinking, they press a button to start a motor. That action starts their day … until it doesn’t.

This article is part of our monthly Tactics and Practices column. Read more Tactics and Practices.

In some situations, a motor may be seen as being inexpensive – a “throwaway.” Spares may be easy to keep stocked. Running the motor to failure may seem to be the best strategy. The cost to replace the motor may be less than the cost to repair it. However, is the cost to repair or replace the motor the only consideration? The cost of downtime and labor hours, as well as any lost production, also needs to be included when measuring the true cost of motor failure. The question that needs to be asked is: What if personnel can extend the operational life of the motor? What cost savings may be gained?

If a plant has a run-to-failure mentality, a failed “throwaway” motor can easily become a big and expensive problem. The process it drives will experience downtime until the problem is corrected. Depending on the motor’s and process’s criticality to production, personnel may be headed into crisis mode. Production may come to a halt without this motor. The choices are:

- Repair the motor

- Replace the motor

Both choices can be costly. Regardless of the path chosen, an operational motor must be in place as soon as possible. In addition to the cost of motor replacement/repair and downtime, the equipment that the motor was driving may also be damaged during the failure event. Because of all of these variables, the actual cost of unexpected motor failure can increase well beyond the motor’s replacement cost.

Principal cause of failure

Electric motor failures are frequently caused by bearing problems. Premature bearing failure may result from any number of factors. Many are lubrication-related; these include over- and under-lubrication and lubricant contamination. Improper lubrication practices can often be addressed via training and focusing on maintenance procedures. Lubricant contamination can also be mitigated.

Common methods for lubricant protection

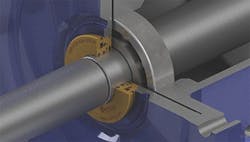

The typical bearing bracket sealing method on an electric motor is a small gap, or clearance, between the bearing bracket and the shaft’s outside diameter. Sometimes, a nitrile “flinger” is placed on the shaft. This is added to literally fling contaminants off the shaft before they enter the bearing cavity. In most applications, these sealing methods are ineffective.

Eliminating lubricant contamination

The best equipment to protect the motor bearing lubricant from liquid or particulate contamination is a noncontact, compound labyrinth bearing isolator. These bearing isolators are designed to keep the majority of contaminants out. Should contaminants enter the interior, the design uses specific clearances, gap changes, and direction changes to control them. The technology directs the contaminants away from the bearing cavity using centrifugal force and gravity. It expels the contaminants outside the seal and away from the bearing. This prevents contamination of the bearing lubricant and greatly extends the life of the lubricant and the bearing.

George Gillespie is a design engineer for Sealing Equipment Products Co. (SEPCO). For more information, visit https://www.sepco.com/bearing-protection/bearing-isolators.

These bearing isolators also keep the bearing lubricant within the bearing cavity, where it belongs. As a result, the lubricant can do its job of keeping the bearing components apart, preventing premature failure. Less contact of bearing components means less wear, which means extended bearing life. Also, this compound labyrinth seal should never need replacement. This provides even greater cost savings.

By increasing the bearing’s life, the electric motor’s life can easily be extended. In many cases, this extension can be a doubling or greater. All of this can be achieved by simply installing proper bearing protection in the form of a nonwearing, noncontact, compound labyrinth bearing seal.