Pressure relief and emergency shutdown technology marches on

The first pressure relief device was developed in 1750, with the invention of the steam engine. Crude by today's standards, it used a weighted metal plate that adjusted to the desired pressure relief. One hundred years later, steam engines developed more horsepower and needed relief devices that could handle higher pressure. The solution was the spring-loaded pressure relief valve, a device still in use today. In 1910, the rupture disc filled a need for pressure relief devices with low initial cost. The rupture disc is still used as an inexpensive relief solution that doesn't demand a highly accurate release pressure. In 1954, Garret Oil Tools introduced the pilot-operated pressure relief valve. It filled a need for larger volume relief in a more compact valve.

|

View more content on PlantServices.com |

In 1986, Shell and Exxon approached Julian Taylor of Taylor Tools and asked him to solve a problem with pilot-operated valves that were failing to operate 5% of the time. The set pressure was 83 bar and the tolerance was 1.5%, a level not possible using conventional methods. The result was the rupture pin pressure relief valve. This relief valve was used in parallel with the existing pilot. Taylor used Euler's Law of Compressed Columns to meet the requirements, and the buckling pin met the challenge and received ASME approval. The ASME standard calls for a maximum setpoint variation of 5%, but rarely do the valves exhibit a deviation greater that 3% from setpoint; 1% is common.

Relieving pressure in a line handling slurries and more viscous fluids requires a full-flow orifice. In 2002, Taylor developed the buckling pin valve, which features a quarter-turn ball valve with a buckling pin actuator.

Figure 1:

One of several valve configurations that capitalize on the buckling pin technology.The technology

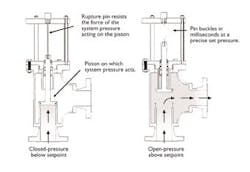

The rupture pin and buckling pin valve are self-contained, self-actuating valves for dependable pressure relief or emergency shutdown at accurately predetermined setpoints. A slender, round pin -- the buckling pin -- restrains a bubble-tight piston or plunger on a seat. Low-tolerance inserts hold the pin at both ends. Too much axial force from system pressure acting on the piston or plunger buckles the pin. Once the pin is bent, subsequent valve action is full and rapid.

The buckling point obeys Euler's Law of Compressed Columns, which depends on the pin's dimensions and material of construction. The temperature-dependent modulus of elasticity is the only variable, and the materials selected exhibit a minimal change over the relevant temperature range. Because the pin is in compression, it can't fatigue. Pulsation in system pressure is not an issue. Because the pin is plainly visible, hidden corrosion is not a concern.

The valve can be pilot-operated and is certified to meet the ASME standard's setpoint variation of 5%. Valve maintenance consists of ensuring the piston moves freely at low system pressure when the pin is removed. Also, the valve can be completely rebuilt in just a few minutes.

There are no limits to valve size or trip points. Rupture pin valves have been built as small as 1/8 in. and as large as 48 in. Pressure set points can be as low as 2 in. of water column to as high as 35,000 psi, and vacuums setpoints as low as 1 psi. The devices can sense system pressure or differential pressure, unlike rupture discs, which only can sense differential pressure. The valves handle corrosive and dangerous fluids and gases with no environmental concerns, because resetting the valve doesn't compromise system integrity. The valves can be glass-lined, made of alloys or plastics. They also can be equipped with a proximity switch to alert the operator of valve action.

The technology also can be used on quarter-turn three-way and four-way ball valves. A built-in actuator clutch offers rapid valve action for pressure relief or emergency shutdown. The first 90 degrees of actuator rotation represents clutch action, which builds momentum so the second 90 degrees provides rapid valve action. The valve can use a pilot tube for sensing system pressure in clean service or have a full-diameter line run to a piston in the actuator for dirty and high-viscosity service.

Lee Levisay is international sales manager at Rupture Pin Technology Inc., Oklahoma City. Contact him at [email protected] or (405) 789-1884.

Figures: Rupture Pin Technology Inc.