Keep fugitive emissions under control with the right valve

More attention worldwide is being focused on fugitive emissions, which are equipment leaks, as opposed to point-source emissions from reactor vents or boiler exhaust stacks. The trend is toward stringent limitations and more scrutiny, and fugitive emissions will be in the vanguard as regulators attempt to impose the next set of emissions standards.

|

View more content on PlantServices.com |

Fugitive emissions are defined variously and might refer to a wide range of emissions not confined to a stack, duct or vent, including emissions from bulk handling or processing of raw materials, windblown dust and other industrial processes.

Not every leak is considered a fugitive emission. Leaks might either be internal or external. In the case of a ball valve, an internal leak could refer to a leak across the seat, from the upstream to the downstream side. So long as the valve doesn’t vent to atmosphere, an internal leak wouldn’t result in a fugitive emission. By contrast, an external leak refers to a leak from inside the valve into the environment, for example, by way of the stem seal or body seal. To the extent that leaks pose harm to the environment, they’re fugitive emissions.

Let’s focus on discrete component leaks, in particular, the external leaks from ball valves, a widely used valve type that enables high flow and effective shutoffs in many industries, including the chemical, petrochemical, oil and gas exploration, power, and alternative fuels industries.

To control fugitive emissions from ball valves, the critical point is to select the right valve for the application. Begin with accurate information about the application. Then, choose the valve technology that most closely accommodates your operating variables. This article can’t address every ball valve type, so it focuses on two design features that are especially important in controlling fugitive emissions and overall cost of ownership: body seal and stem seal designs.

Body seal design

Two common types of body seals are screw type and flange type. The screw type provides a stronger seal that tolerates higher system pressure, but the flange type allows for fast and easy maintenance with the valve in line.

The screw type consists of one or two threaded end screws affixed to the valve body after the ball and seat packing have been loaded inside. The sealing area of a screw-type fitting is relatively small and can be an especially efficient seal, enabling effective sealing at pressures as high as 10,000 psig or 20,000 psig (689 bar or 1,378 bar).

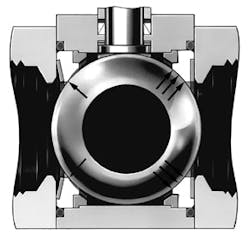

Valves using the flange-type body seal have three discrete sections that are joined together with flanges, seals and bolts (Figure 1). The sealing area across these components is larger, so this design usually results in a lower pressure rating. Because the flanges are sealed with gaskets, there are fewer geometric constraints on the sealing material and, therefore, a wider choice of sealing materials is available.

Valves having a flange-type body seal consist of three discrete parts that are joined together with flanges, seals and long bolts. Such valves come apart for easy repair in situ.

Beyond sealing materials, an advantage of the flange-type design is ease of maintenance. Once the bolts are removed, the valve’s body swings out for easy repair without removing the entire valve from the system.

A ball valve requires some means of ensuring that the system medium, whether liquid or gas, doesn’t leak from the stem and body interface. This is the role of the stem seal. With sufficient cycling frequency, stem seals are subjected to wear, and wear can lead to leakage. However, some seals are more effective than others in certain applications.

One-piece stem packing

The most basic technology is a one-piece gasket that encircles the stem. As the packing bolt is tightened down on the stem, the gasket, usually made of polytetrafluoroethylene (PTFE), is crushed, filling the space between the stem and the body housing.

Unfortunately, PTFE and similar packing materials are subject to cold flow, which is the tendency for certain materials to change shape over time. Cold flow can be exacerbated by pressure and temperature. In some cases, the material might extrude into areas where it wasn’t intended to go, undermining its effectiveness and leading to leakage.

To compensate for cold flow, the packing bolt might need to be tightened frequently to maintain a constant compression load on the stem seal. With enough retightening, the packing bolt might bottom on the valve body, at which point the packing will need to be replaced.

This basic packing technology requires frequent inspection and adjustment; otherwise, leakage might occur. Unfortunately, to the untrained operator, it’s not always clear when adjustment is required.

Two-piece chevron stem packing

A two-piece chevron stem packing is an improvement on the one-piece design and allows for wider temperature and pressure ranges, as well as regular and easy actuation without excessive wear.

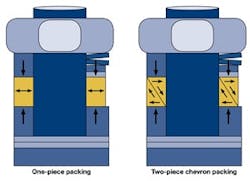

A chevron packing consists of two matched gaskets, one fitting inside the other. The cross section of the gaskets is triangular. Fitted together, the two gaskets form a rectangular cross-section (Figure 2). As force is applied from the stem’s packing nut, the two gaskets are pushed against each other along the diagonal point where they meet, which distributes the force horizontally and evenly against the stem and body housing. A minimal pressure from the packing nut produces a substantial seal between the stem and the body housing.

On the left is the standard one-piece packing. On the right are the two ferrules that make up a chevron stem packing. In the chevron packing, minimal pressure from the packing nut pushes down on the two triangular shapes, resulting in outward, even pressure between the stem and the housing.

For the chevron seal to work correctly, the two PTFE gaskets – the packing – must be held in place to reduce cold flow during thermal cycling. The packing in the chevron design, therefore, must be adequately contained and supported by packing support rings and glands, which evenly distribute pressure to the packing.

To increase the interval between inspections and adjustments, the chevron design also might include Belleville washers, which are springs that produce a live load on the packing. Live loading places uniform force on the packing: As temperatures and pressures fluctuate, the springs provide a constant bias force against the seal and the body to maintain the appropriate amount of sealing force.

O-ring seal

Another effective stem seal technology is the O-ring. When properly designed, O-rings provide flexibility for applications requiring high pressure, low pressure, or a broad pressure range, such as a cylinder, where, for example, pressure might drop from 2,300 psig (158.5 bar) when full to 100 psig (6.9 bar) as it nears empty.

The O-ring is usually made from a highly elastic material, such as fluorocarbon FKM. Like the two-piece chevron design, the O-ring design doesn’t require excessive packing nut pressure. Rather, the O-ring is energized by pressure in the media stream. As that pressure increases, the O-ring further deforms and increases pressure on the stem. Conversely, as pressure in the gas stream decreases, the O-ring relaxes, filling the space between the stem and the body.

A proper stem design with an O-ring configuration requires a back-up ring or some other mechanism, usually made of PTFE, which contains the O-ring under high pressure. This back-up ring reduces the extrusion gap of the O-ring gland and thereby keeps the O-ring contained. If the O-ring is permitted to extrude beyond specific limits, it might be sheared during actuation.

The O-ring design is highly effective at high pressure. In terms of temperature, pressure and chemical attack, the design is limited by the properties of the elastomer.

Stem misalignment

Beyond issues relating to stem seal design, there are some additional causes of stem leaks. These have to do with stem alignment. If for any reason the stem becomes tilted or forced to one side, there might be uneven wear on the stem seal, resulting in leakage.

There are two basic causes of misalignment. In the first, misalignment might result from improper actuator installation. If the actuator and stem centerlines aren’t properly aligned, the stem tilts or skews, resulting in uneven stem seal wear.

In the second case, damage to the seat seal inside the valve might cause the stem to tilt. To understand this issue, we must first review basic ball valve anatomy. Ball valves can have either a floating or trunnion ball design.

In a floating ball design, the ball isn’t fixed inside the housing but, rather, floats between two seats. In the shutoff position (Figure 3), the ball seals against the seat on the low-pressure side, pushed downstream by a positive pressure differential.

A cross-section of a floating ball valve in the shut position shows downstream pressure pushing the ball to seal on the right-hand side. Arrows indicate the contact with the seat seals.

By contrast, the trunnion design uses a ball, but it’s not a discrete sphere. Rather, its geometry includes two cylinders - the trunnions - affixed to the ball at the top and bottom (Figure 4). The unit fits into a space in the valve body and can’t move along the flow axis. As the ball rotates from the open to closed positions, it glides on the trunnions, which can be fitted with bushings or bearings.

In the case of high differential pressure across the seat, a free-floating ball can be pushed downstream – too far downstream. In the absence of an advanced seat design – such as a spring-energized seat with an O-ring and spring on each side – the ball might not return to the center position. As a result, the stem will tilt to one side, and, with time, uneven stem wear will occur.

The trunnion design prevents excessive movement of the ball downstream. The trunnions keep the ball centered and the stem properly aligned.

The different ball valve designs have appropriate applications, strengths and relative merits, and these have a direct effect on fugitive emissions. When choosing a ball valve, give due consideration to material compatibility, pressures, temperatures, desired frequency of inspection and adjustment, and frequency of actuation. Further, when cost becomes a leading valve selection determinant, be aware of the compromises you might be making.

The trunnions support the ball assembly.

The real cost of a valve isn’t its purchase price, but the overall cost of ownership. With raw material and feedstock prices increasing, the frequency and severity of environmental noncompliance fines, and direct and indirect costs associated with frequent maintenance, you must account for valve upkeep, failure and replacement.

Michael Adkins ([email protected]) is general industrial valve product manager and Peter Ehlers ([email protected]) is alternative fuels market manager for Swagelok Co., Solon, Ohio. Contact them at (440) 349-5934.

Figures: Swagelok Co.