High temperature plants need to be run safely and be efficient. A heat transfer fluid (HTF), either synthetic or mineral-based, is used in manufacturing and production plants for prolonged periods. Over time they thermally degrade to produce light and heavy-chain hydrocarbons. With effective management and monitoring, these can be removed to sustain the long-term health of the fluid and the plant.

Understanding the advantages of double-acting actuators

Back to basics: Fluid sealing school

The cleanliness of an HTF is essential to the long-term operation and safety of a manufacturing facility (e.g., processing of food, chemical manufacture and energy production).

As a HTF degrades it produces long (“heavy-ends”) and short-chain (“light-ends”) hydrocarbons, which alter the safety and efficiency of the plant. For instance, a HTF will thermally crack and flash point temperatures will steadily drop. This indicates that a HTF system is not venting properly and fuel-like decomposition by-products start to accumulate in the HTF system and increases the flammability of the HTF. These must be managed to ensure the safety of the system.

A light-ends removal kit (LERK), as it suggests, is used to remove light-ends from the system and maintains light-ends within accepted normal limits.

This article is part of our monthly Tactics and Practices column. Read more Tactics and Practices.

Routine sampling and analysis of a HTF is used to quantify the extent of light-ends in a fluid. The specific parameter of interest is the measurement of closed flash point. As light-ends accumulate in a system, the closed flash point starts to decline. The objective of monitoring is to identify changes that require a corrective action. The primary objective is to maintain a closed flash point within normal limits.

There are several interventions that can be taken to normalize closed flash point temperature.

One of the more costly options is to completely replace the HTF, but this will interrupt production because the old fluid will need to be removed before a virgin fluid is added. Another option is to use batch venting where the expansion tank is heated temporarily to raise the temperature of the fluid and to release the light-ends from the system. However, this can be detrimental to the fluid as it may accelerate thermal degradation and oxidation. Another option is the installation of a LERK, which works continuously to remove light-ends via distillation from the HTF system.

Chris Wright is a research scientist, graduating from the University of Leeds in the UK with a BSc and PhD. His research focuses on the use and maintenance of heat transfer fluids in manufacturing and processing, which includes food, pharmaceutical, specialist chemicals and solar sectors. He can be reached at [email protected].

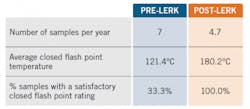

LERKs can be extremely effective in the control of closed flash point temperature. A recent analysis published in the journal Heat Transfer Engineering demonstrated that closed flash point temperature was stabilized for the 11 years after a LERK was installed. During this time closed flash point needed to be monitored less frequently (i.e., fewer samples per year), was maintained at a higher closed flash point temperature, and more samples with a satisfactory closed flash point temperature were achieved when compared with the period before installation (the chart above summarizes the key findings).

These findings highlight the value of the LERK in terms of improved fluid condition and plant safety. It is important to remember that a HTF still needs to be regularly sampled so that any changes in condition can be detected early during the degradation process and interventions can be taken should an action be needed. Regular sampling includes a series of tests that assess the overall health of the fluid, such as the build-up of longer-chain hydrocarbons, produced as a by-product of thermal degradation, fluid oxidative state, viscosity and the presence of foreign particles and contaminants (e.g., water).

This story originally appeared in the March 2022 issue of Plant Services. Subscribe to Plant Services here.