Student team evaluates AI-powered ergonomic safety tool

Key Highlights

An assessment of the SoterGenius industrial tool by a student team at the UT-Knoxville Reliability and Mantainabiltiy Center found the following:

-

AI tools like SoterGenius can simplify OSHA compliance by analyzing images and videos of workplace tasks.

-

SoterGenius can identify unsafe lifting techniques and provide data-driven recommendations to reduce injury risk.

-

The Hazard Identification Pro feature enables deeper video analysis, flagging potential OSHA violations before accidents occur.

SoterGenius is an AI-powered tool for industrial companies, which analyzes images and videos to make compliance and inspections easier for predicting and preventing workplace accidents. Specifically, it analyzes against OSHA guidelines to identify gaps in safety, allowing the user to take corrective actions.

Recently a Senior Design Project team at the University of Tennessee’s Reliability and Maintainability Training Factory set out to explore the technology’s capabilities. The team is evaluating the SoterGenius tool in two phases:

- Phase 1 (1st Semester): Familiarization and preliminary test phase

- Phase 2 (2nd Semester): Utilize the technology in real-world application

This article summarizes the results of Phase 1 of the student evaluation project.

Ergonomics Testing: Evaluating Lifting Safety and OSHA Compliance in Manufacturing Tasks

The team’s Phase 1 task was to lift cases of water bottles from a pallet on the floor, relocate them ~20 ft, and stack them on a 30-inch-high elevated shelf for storage. For this task, the project team took pictures and filmed themselves performing the work, and then fed those photos and videos into the SoterGenuis platform, which is designed to audit the uploaded content and identify elements that are unsafe and/or are non-compliant with OSHA regulations.

Figure 1 shows the report generated by SoterGenius during the Phase 1 task.

The next step of the project was to ask SoterGenius for further details on how to adjust the task in order to ensure compliance with OSHA standards. By inputting the required variables for the Revised NIOSH Lifting Equation, SoterGenius was able to calculate the lifting index and identify factors contributing to unsafe lifting techniques over extended periods (see Figure 2).

Reducing Injury Risk: How SoterGenius Identifies Unsafe Techniques and Improves Industrial Ergonomics Training

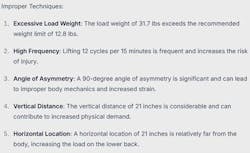

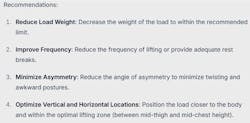

As the team reviewed the list of improper techniques generated by SoterGenius, they saw four areas for improvement that would lower the lifting index (see Figure 3). This information is extremely valuable when trying to reduce the risk of injury. SoterGenius then provides general recommendations to help mitigate the risk of lifting-related injuries, which is particularly useful when teaching ergonomics practices.

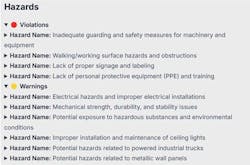

Beyond lifting evaluations, SoterGenius has many other capabilities, such as its new Hazard Identification Pro function. This feature analyzes photos or videos in greater depth at a more advanced level, and utilizes motion capture capabilities to analyze videos of work tasks and identify potential OSHA violations and near-violations (see Figure 4).

Preliminary results

The Senior Design Project team considers SoterGenius to be a highly adaptable tool that simplifies the implementation of safety procedures by minimizing the need for specialized expertise. Its intuitive chatbot interface enables users to quickly understand and apply safety protocols, making proficiency achievable with minimal training.

As stated by Dr. Klaus Blache, UT-RMC Director, “it’s a practicable technology that is easily deployed.” This accessibility presents exciting opportunities, as AI-driven tools like SoterGenius can revolutionize ergonomics education by delivering innovative, interactive training methods that are both efficient and effective.

A future article will present the results of Phase 2 of this student investigation, to utilize and evaluate the technology outside of a lab environment in a real-world application.

About the Author

Stephen Mundy

Stephen Mundy is a consultant to the UT-Knoxville Reliability and Maintainability Center.

RMC-UTK Senior Design Project Team

The RMC-UTK Senior Design Project Team includes Autumn Erwin, Jacob Anderson, Lauren Haggerson, Emma Davis, Evan Ellison, and Danielle Tabar.