Maintenance planning-scheduling-kitting best practices at Alcoa Warrick Smelter

In 2003, Alcoa’s aluminum smelter east of Evansville, Indiana, was 43 years old, with the second-highest maintenance (R&M) costs in the corporation’s global smelting system. Asset reliability in the plant continued to suffer, and equipment instability was preventing lean manufacturing. A formal assessment of the smelter’s R&M efforts determined a mostly reactive approach with a focus on trying to be really good at emergency breakdown response.

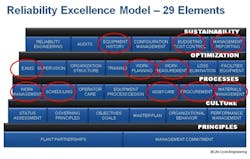

With strong sponsorship in 2003, the location embarked on a Reliability Excellence (REX) transformation. Ten years later in 2013, Alcoa Warrick Smelter’s R&M costs are 29% below its 2003 pre-REX base (44% lower adjusting for inflation) and OEE performance improvement gains are worth another $9.5 million annually (Figure 1).

Figure 1. Alcoa Warrick Smelter lowered its normalized maintenance costs from 2003 to 2013.

A formal asset integrity audit performed in 2010 by corporate-level resources confirmed that these cost savings were not gained from deferral of R&M. In fact, the Warrick Smelter had the lowest percent of corrective actions needing attention in the next five years among the corporation’s smelters across the globe.

We are convinced that REX was a huge game changer saving significant costs. In fact, the Warrick smelter has been recognized by the corporation for these efforts, and our team was proud to share our REX success at the 2013 SMRP Conference.

This case study describes the maintenance planning-scheduling-kitting best practices now in use at the Warrick Smelter and how these practices are an integral part of REX at the 53-year-old facility.

Reliability excellence cost savings levers

When Warrick Operations began its REX journey in 2003, Alcoa’s consultant said that unplanned-unscheduled emergency R&M jobs were seven times more expensive than planned-scheduled jobs. Furthermore, running equipment to failure was 10 times more expensive than discovering potential equipment failures early with thinking that was focused on both preventive maintenance and predictive maintenance.

Planned-scheduled R&M jobs have the potential to be 10 times safer than emergency work because there are fewer “error traps” like time pressure, distractions, vague work guidance, poor communications, and stress. All of these conditions can contribute to injuries. The smelter’s maintenance total injury rate was 8.7% in 2001-2002. More recently, Warrick’s Smelter has lowered that to 0.9% for the past three years.

What it means for an R&M job to be planned: We believe a planned R&M job has the following characteristics. This is our REX target condition. Our six planner schedulers strive to meet all these characteristics before a maintenance job is put on the schedule for our 99 craft personnel:

- an accurate time estimate for the job so the supervisor can have a reasonable expectation on when to assign the next task

- accurate estimate of craft personnel.

- listing of all equipment, JLG, welder, any special tools from the crib, and anything else needed to perform the job

- information available (prints, permits, LOTO)

- job step sequence, procedure, and instructions to accomplish tasks of the work

- parts and materials kitted and ready

- as a “built-in check” to assure a quality planned job, schedulers periodically discuss the nature of the job with the supervisors and/or personnel assigned to complete the job (This ensures there is a full understanding of scope of work and that all materials for a job package are complete before it begins).

If an R&M job is put on next week’s schedule that doesn’t meet these characteristics, what happens? A craftperson is assigned the unplanned job and now that person must do most of these steps “on the run.” What if the craftsperson cannot find parts or access special equipment or needs prints? What if the craftperson must secure equipment from operations? Is the LOTO well documented? When will the job be complete? The completion time is unknown because there are no standards for unplanned jobs.

What it means for a planned R&M job to be kitted: We have a 100-by-150-ft secure area that is dedicated to planned R&M job kits. Alcoa Warrick Smelter’s planned R&M work kitting area is secure 24/7.

This kitting area was one of Warrick’s first REX successes in 2003, and we started with an area half the current size. Previously, we attempted to kit jobs in an unsecure stores delivery area near the job site. We had more than 50 delivery locations scattered around the plant. Imagine the probability of success with that effort. Some of our jobs have dozens of components that take several weeks or months to acquire. It was common for received parts to go missing by the time we believed the job was ready to perform.

Initially our kitting area was zoned by planner and parts for a job were put on racks. We soon evolved to having a basket system and visual tag system. A red tag is shaped like a stop sign and says the kitting is in progress, not ready. A yellow tag is shaped like a triangle and says the kit is complete but not scheduled. A green tag is round in shape and says the kit is complete and scheduled.

Our approach in 2007 did not enable effective planning-kitting-scheduling. In 2007, we had only 1.5% of our craft resources performing predictive maintenance (PdM) diagnostics, and we rarely acted on our predictive maintenance anomalies. Our PM % was 31% of total craft hours, and it only generated 400 corrective work orders. This 41:1 ratio was much worse than the 6:1 ratio that one would target and expect with REX.

Much of our R&M work was reactive and emergency work with short lead times, not allowing for proper planning-scheduling-kitting. Through extensive PM kaizens (Phase I-Phase IV) conducted by our two reliability engineers, the smelter at Warrick reduced its PM level from 31% to today’s 19% level while increasing predictive maintenance from 1.5% to 14% present day, freeing up significant craft hours each year. In other words, the savings from reducing PMs have helped finance the predictive maintenance effort, allowing planner-schedulers to thoroughly plan and kit corrective repairs.

The REX Model

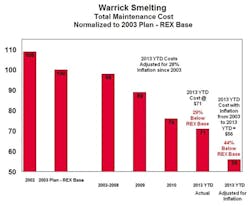

The REX Model used by the consultant we employed, Life Cycle Engineering, emphasized the importance of planning, kitting, and scheduling in 11 of its 29 elements (Figure 2).

Figure 2. The REX Model was implemented at Alcoa Warrick Smelter by Life Cycle Engineering.

These 13 aspects are what Alcoa considers best practice for the planning and scheduling process. Although not shared here, for each of these 13 aspects, we have articulated a minimum acceptable standard and also what we believe is a best practice level of operation.

Work request: Maintenance work is requested utilizing a computerized maintenance management system (CMMS) and approved by the asset owner.

Review requested work in field: Increase planner efficiency in the field when confirming and gathering job scope requirements for one-time jobs. The use of a field job scope document eliminates repeated visits to the field.

Work order: This is the mechanism for planning and executing maintenance work.

Asset activity: This is a standard work instruction that provides all of the details necessary to perform work, including a list of materials, resources, tools, documents, and instructions. This includes asset activities and pre-plans.

Backlog management: Select jobs (W/Os) for planning and future scheduling. This is the planners’ routine activity of continually building the ready and total backlog.

Confirm materials and parts availability: This is confirmation that ordered parts are received on site and are available for the planned date.

Five-week plan and resource availability: Facilitate effective planning of resources beyond the week of execution (next week), providing a longer term vision to ensure efficient work execution.

Preliminary schedule: This is the first draft of the next work week’s schedule, available by Tuesday evening of the week before, for final approval by the asset owner. This also includes preparation for the weekly scheduling meeting

Weekly scheduling meeting: Maintenance and operations set the schedule for the following week and review the performance of the previous week’s activities (KPI review).

Prepare work packs: Assemble all necessary documents, information, and lists to allow efficient execution of the work order.

Publish the weekly schedule: Provide all affected parties with a copy of the approved weekly schedule in time to allow a review and confirmation that it is accurate.

Close work orders: Complete the W/O process, preserve CMMS data, and preserve the transactional data and content of CMMS. Close off cost charging to the W/O.

Regular communication between planner and maintenance supervisor: Provide an environment for communication and feedback. Ensure the planner has knowledge of issues and activities in the field to enable an effective planning function.

Essential aspects of kitting

These nine aspects are what Alcoa considers best practice for kitting. For each of these aspects we have articulated a minimum acceptable standard and also what we believe is a best practice level of operation.

Job material pack (JMP): This includes the complete JMP kit of all materials and parts specified in the W/O bill of material (BOM). Facilitate the delivery of all specified materials and parts to the work site for scheduled work execution to improve craft wrench time.

JMP identifier: Uniquely identify the JMP for each W/O. Establish a clear link from the JMP to the work to be executed.

JMP status: This is a highly visual indication of the progression of the JMP process.

Planner review and verification: Identify potential issues during JMP (kit) assembly early to resolve problems prior to work execution. Verify JMP completion with all W/O specified parts/materials.

JMP tracking: Show the progression status of all JMPs that are behind schedule. Note actions taken to minimize scheduling impact.

Staging areas: This is an area where the completed JMP will be stored. JMPs are readily available for pickup and delivery to the requesting department. Parts/materials are stored in a manner that will preserve their integrity.

JMP effectiveness: JMPs are accurate and complete to facilitate effective work execution. Metrics are in place to measure the effectiveness of the kitting process.

Return to stores or vendor: Allow unused items (parts/material) to be returned to the stores for return to the stock inventory and reuse. Credit the department for unused parts via W/O. Allow unused OOR or direct purchase items to be returned to the vendor for credit.

JMP daily management board or mechanism: Track and display status of each JMP, and log problems and actions.

Lessons learned

Some hard lessons were learned by our location in the implementation of REX.

Develop a secure kitting area: This is a “must have” to ensure success.

Inflated PM activity: PMs can resemble lumber 2-by-4s, 2-by-8s, and 2-by-12s. Or frequency may be too often. PM content may be too vague to add value. As a target, six PMs should yield one PM corrective work order. Don’t let inflated PMs crowd the weekly R&M schedule.

PM kaizen process: Our PM kaizen process is conducted annually to clean up old PMs. This has generated 55,000 craft-hours for more value-added craft work in PdM and corrective repairs.

Having wrong people in planner scheduler jobs: Make sure you have qualified people in planner/scheduler roles. Too much is at stake with millions in R&M budgets.

Don’t let unplanned jobs get on next week’s schedule: This is a quick way to lose credibility.

Double check your metrics: It’s easy to mistake metrics. “Trust but verify” is the best policy. Years ago we thought we were 90% planned R&M, and then we discovered the number was really about 40%, and most of that was our inflated PMs.

Do we really need a storeroom full of spare parts?: Today 50% of our spare parts for planned-kitted-staged jobs come brand-new from the supplier with our focus on 4-6 weeks of ready planning-scheduling backlog. In reality, our storerooms are big countermeasures for emergency R&M.

Resist the temptation: Don’t perform extensive PM-related corrective work during a PM unless it’s truly safety-related and/or very short in duration (30 min maximum). It’s unplanned work and expensive.

Common for old PMs to have inspection and repair time both built into time allotted: Not reducing PM hours accordingly creates a hidden R&M workforce and corrupts all of the R&M metrics. For example, today’s 4- and 8-hour PMs all completed by 9 AM; 100% PM compliance achieved; 100% schedule compliance achieved; 100% planned work achieved. What to do with craft folks for the rest of the shift? Divert to emergencies, assign to work not on schedule, % emergency work now is understated. At worst, assign no craft work the rest of the day.