Thermal growth and alignment

The fact that machinery moves during operation is established and well documented. Many manufacturers of rotating equipment provide expansion data for their products derived from theoretical calculations. However, no matter how careful one is in approaching these calculations, unavoidable limitations are frequently encountered when applying pure theory to field situations. Some factors posing problems to theoretical growth calculations for alignment are:

|

View related content on PlantServices.com |

* Piping size and length.

* Downstream temperatures.

* Load changes.

* Machine frame distortion due to torque.

* Uneven materials heating.

* Foundation problems.

* Ambient temperature changes.

* Process effects.

An agricultural byproducts manufacturer in the north central United States was experiencing problems with premature bearing failure on a number of its motor-blower assemblies. Through vibration analysis, maintenance personnel concluded that misalignment was a probable major factor contributing to excessive bearing wear. They decided to investigate online positional measurements to verify manufacturer's recommended alignment targets.

Three alignment methods

Bengal Resources Inc. of Atlanta was contracted to obtain cold alignment targets for a single motor-driven blower. The tested unit, manufactured by Hoffman, is driven by a 125 HP motor and located indoors.

The objective was to obtain accurate cold alignment targets. These targets can be used to deliberately misalign the assembly while cold so rotational centerlines might "grow" into a straight line under normal operating conditions.

Three measurement methods were selected:

1. Optical scopes: Monuments were installed on each side of bearing housings on both the motor and blower. An optical level and a jig transit from Brunson Instruments (www.brunson.us) were used to measure changes in vertical/horizontal positions of monuments at offline and online conditions. Accuracy on this system is better than 2.0 mils.

2. Continuous laser monitoring system: Permalign laser monitors and reflectors from Ludeca (www.ludeca.com) were installed in standard configuration. A biaxial photo detector gives measurement resolution of 1 micron, and system accuracy is better than 2% of displayed value.

3. Periodic laser measurement of casing position: A standard laser shaft alignment system (Rotalign Pro from Ludeca) was used on a bracket to obtain periodic relative positions between machine assembly casings. Sensor resolution is 1 micron and 10 micro-radians. Displayed values are accurate to within 2%.

The unit was taken offline two days before installing instrument bracketing and monuments to be sure the metal casing reached ambient temperature.

Offline positional data was recorded using standard methods. The continuous laser monitoring system was initiated to automatically record alignment changes every 10 seconds throughout the measurement cycle.

The motor was energized and brought to full load. Heat soak conditions were achieved after about four hours of operation. Periodic laser measurements and optical data were collected at this time to serve as the stable online position.

Specifications verified

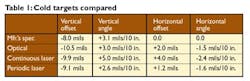

Table 1 compares the various measurement methods to each other and to the manufacturer's recommended cold alignment target.

Differences recorded generally fall within the tolerance range for this category of equipment with the exception of the manufacturer's horizontal alignment targets. Notwithstanding this exception, it was determined that adherence to the manufacturer's alignment targets should not have been sufficient to cause the experienced level of premature bearing failures.

Most bearing failures are observed to occur on outdoor units. The agricultural products company is currently considering the following actions:

1. Determine seasonal alignment targets and increase frequency of machinery alignment to those targets.

2. Construct enclosures around all outdoor units and align to adjusted manufacturer's alignment target.