Save money with these motor system reliability considerations

Like plastic cards, in many regards the electric motor fits the phrase “buy now, pay later.” The initial cost of the motor is a negligible fraction of its total cost of ownership. Minimize the cost of ownership not only by using only highly efficient motors, but by paying attention to the costs associated with unreliable motors driving your process or equipment.

Motors are central to the operation of many industrial processes and motor failure almost inevitably leads to equipment failure. One reason motor reliability is important in the industrial sector is the huge costs associated with lost production and downtime. Motor reliability is crucial to equipment operation and smooth-running processes, and an unreliable motor can be costly.

Why motors fail

Over many years, we’ve learned which motor components fail most often. Most issues related to induction motors, the industrial workhorse, apply to other motor types as well. It’s well known that bearing failure is the predominant motor failure mode, followed closely by winding failure. A survey by the IEEE subcommittee on power system reliability on large industrial and commercial motors and an independent study by EPRI confirm that bearing failure is the leading reason for motor failure.

Together, bearing and winding failures constitute at least 60% of all motor failures. The survey on large motors also reported that 37% of bearing failures and 33% of winding failures occur during normal plant operation.

Plant and maintenance personnel don’t get excited when a motor fails in normal operation and they’d rather be working the other shift when it happens. However, a system to detect incipient faults and warn of imminent failure on every motor would be too costly, so such systems are applied only to critical motors. Therefore, some failure rate is inevitable in normal operations.

But, how many motor failures can the plant tolerate? Whether the issue is large motors operating in plants or small motors operating in an OEM’s main product line, the realities of the global market provide common ground for the way users approach motor issues. Many industries, manufacturers and end users are under intense pressure to reduce the cost of production, the cost of products and cost of warranty claims just to stay competitive.

In the quest to reduce costs, every dollar counts and the cost of the drive motor is a primary item that comes up frequently. For large facilities, OEMs or anyone who buys motors by the truckload, a dollar of unit cost saved is a big deal. But when motor cost is on the radar screen, it’s important to evaluate the reliability of other manufacturer’s offerings against the motor that’s been giving you a headache. The number of candidates depends on the confidence level you require and how much you want to spend on the evaluation.

If your motors have been reliable in the past, you’re faced with tough questions:

- How do we move to a new, unfamiliar motor?

- How can we make sure it will work well here?

- How will this change affect our life-cycle cost?

These are but a few questions that arise, and getting answers isn’t easy because the answers are inextricably linked to motor reliability.

Define motor reliability

Reliability is the probability that a system will perform satisfactorily for at least a given time period when used under stated conditions. This probability, expressed as a function of time, is called the reliability function, R(t). For years, reliability engineers have used mean-time-to-failure (MTTF) to measure reliability for non-repairable equipment, and mean-time-between-failures (MTBF) for repairable equipment. Assuming a constant failure rate (lambda) and an exponential distribution, the mean time between failure and the reliability function (R(t)) are expressed as:

MTBF = Total operating time/Number of failures

Properly applied motors usually exhibit high reliability and also are generally repairable. However, in most cases, it makes more sense to replace small motors than to repair them. The events that are considered as total or partial failure will vary by equipment type and by plant. While total failure is easily understood, partial failure is difficult to generalize and the user must define it depending on the level of trouble-free operation required.

From the definition of MTBF, it’s clear that quantifying reliability requires accurate and dependable data. Plant personnel can collect dependable historical failure data during operation and use it to evaluate reliability, but this is much more involved than it seems because plant personnel must take note of the reasons for failure, which could be time consuming or impossible. Also, the operating environment must be recorded because different motors in different environments are exposed to different conditions.

Another way to get failure data is through model predictions, which analyze equipment and system components to determine the failure rate of the entire assembly by using complex mathematical formulations.

The empirical method for getting failure data is through physical testing. This approach is more suitable for small motors.

Reliability tests

You might need a number expressing motor reliability for some critical process. Obtain this reliability number by a carefully designed testing of a number of identical units. There are two main ways this can be achieved.

The first involves measuring the time to failure for a sample population of motors, fitting the data to an appropriate distribution, and analyzing the results, which reveals the probability of the motors having a particular lifetime. The sample of motors needs to be tested until each fails, and no one can predict how long that might take. These tests monopolize special laboratory facilities and equipment for the duration of the test program.

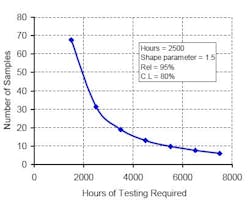

The second approach specifies the desired motor reliability over a given life cycle and tests a statistically significant sample to demonstrate that the product meets the reliability goal. Figure 1 shows a typical graph of an analysis showing the number of samples to test as a function of test duration needed to demonstrate 95% reliability and 80% confidence level using a Weibull shape parameter of 1.5 with no failures allowed. This means that 95% of a given motor type will achieve a life of 2,500 hours. The life-hours vary from equipment usage in normal life because equipment used intermittently accumulates fewer hours over several years. The data shown in the chart is from a real test program.

Figure 1. Sample quantity versus test duration to demonstrate 95% reliability at 80% confidence with no failures allowed.

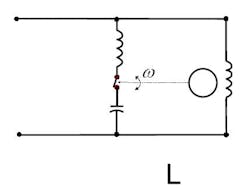

As shown in the graph, you can either test a few motors over a long time or test a large number of samples for a relatively short time; both situations being expensive. A compromise solution can be found through accelerating the testing with a reasonable number of samples. Statistical tools analyze the data to determine reliability. Fortunately, most of the failure patterns of electromechanical equipment can be represented by well-known distributions such as the normal (or Gaussian), exponential or Weibull. (The reliability information that results directly influences the OEM’s warranty policy.) A rig for testing motor systems for reliability is shown in Figure 2.

Fig. 2 Reliability testing rig is used for smaller motors.

These methods are practical only for single-phase motors and three-phase motors smaller than 5 hp, which, fortunately, reflect a large proportion of the industrial motor population. It’s estimated that about 60% of the U.S. integral horsepower motor population is rated between 1 hp and 5 hp and about 80% is rated between 1 hp and 20 hp. These tests aren’t feasible for larger motors. When these fail, they’re repaired using best repair practices, and motor build inspection analysis helps improve operational reliability.

Testing small motors

Equipment driven by single-phase induction motors generally develops problems with the starting circuit components (start capacitor, centrifugal switch, starting winding), which are more prone to premature failure than other motor components. Figure 3 shows a 7.5 hp single-phase, double-capacitor motor and a typical centrifugal switch, while Figure 4 shows a schematic of a typical capacitor-start, induction-run single-phase motor. The start winding is usually an auxiliary winding intended for starting the motor and is disconnected from the power source by the centrifugal switch after the motor attains a given speed.

Figure 3. Double-capacitor, single-phase induction motor (top) and centrifugal switch (bottom).

Figure 4. Schematic of a capacitor—start, induction-run motor.

An endurance test might involve cycling the motor on and off rapidly under load to subject the starting components to severe stress. Also, the rapid cycling subjects the motor to the inrush current and severe electromechanical forces that can be hard on windings that aren’t properly secured. These forces can elevate mechanical stresses on the entire motor assembly, including the motor mounts. Furthermore, the rapid cycling can overheat the motor windings and bearings, thereby accelerating motor failure. The tests must be designed so the failure mechanisms of interest are accelerated. This means that failures unrelated to the mechanism under consideration must be ignored.

Large motors defy testing

It’s impractical to subject multiple large motors to the previous test regimen. Instead, historical data on the motors operating in the plant would be useful. But, only a few plants keep sufficiently detailed records of their motors and failures. Also, in a typical plant, the number and types of motors are so varied, manufacturers are so different, and motors operate in such different conditions with different maintenance practices over different time periods that it’s debatable whether a statistical number for MTBF would be meaningful for quantifying reliability.

To minimize the cost of reliability, some users perform vendor qualification testing to provide some assurance for new motors they are considering. This involves a battery of performance tests, including temperature rise, locked rotor and breakdown tests as well as motor build and inspection analyses (MBIA).

In the MBIA, the sample motors are torn down to investigate and compare component quality to the incumbent. Also, plants should consider installing severe-duty motors, such as IEEE Standard 841 motors, if the motor might be exposed to harsh conditions. The 841 motors have been specifically designed to survive in the chemical and pulp and paper industries.

Determine and document the cause of motor failure. Include maintenance history and whether the motor was a new or repaired. Then, using tools such as the Motor Master, decide whether to repair or replace.

It’s important that you make this decision only after a thorough failure investigation.

The data will come in handy some day and form the basis of future reliability decision-making. For example, assuming a plant establishes that a new motor lasts twice as long as a rewound motor and there are large costs associated with the process downtime, then there should be some benefits derived from a motor that fails less frequently. This benefit can easily be calculated using an Excel spreadsheet.

If you decide to repair, write a good repair specification and ensure that the repair facility is qualified.

The U.S. Department of Energy (DOE) has developed guidelines for motor repairs that can be accessed on the Web. Also, a list of qualified service centers as well as guidelines on good repair practices can be obtained from the Electric Apparatus Service Association (EASA). Furthermore, there are certification programs available to qualify motor service centers. Usually, motor service centers that are accredited by the Advanced Energy’s Proven Excellence Verification (PEV) certification program have demonstrated full competence supported by rigorous audits and testing.

Emmanuel B. Agamloh is Sr. Motor Systems Engineer at Advanced Energy in Raleigh, N.C. Contact him at [email protected] and (919) 857-9023.