Rethink motor repair/replace decisions: Does the 57% threshold still apply?

A 100 hp motor on your plant’s cooling-water pump just failed. Its performance had been declining for six months. You can get by for a couple of weeks with a spare unit, but it was taken off the line because it showed signs of vibrating. Now the question that lingers in the air even more pervasively than the scent of burned insulation is: Do I repair or replace the failed motor?

This scenario is played out every day in the nation’s manufacturing facilities. A generation ago - before the advent of energy-efficient motors – this motor decision was relatively simple and was made on the basis of the cost of the repair versus the cost of a new motor. If the repair cost wasn’t more than 57% of the cost of a new motor, the choice was to repair it. The 57% threshold was based on a combination of economical analysis and the knowledge that a rewound motor of that era would rarely last as long as a new one. It was an empirically determined maximum that most plant managers were willing to pay for a repaired motor.

With the coming of energy-efficient motors, the repair/replace decision variables changed because it was easy to show that on long-running applications – 2,000 hours per year or more – the lion’s share of the motor’s life cycle cost lay in the amount of energy used. Energy savings with the new motors – in excess of $1,000 per year for a 200 hp motor – were so large that the price of a motor, by comparison, became insignificant. Thus, as motor selection became a watts-management issue, failure of every standard motor was seen as an opportunity to upgrade to an energy-efficient unit that could pay for itself in energy savings. For applications such as ball mills, compressors, cooling towers, HVAC, pulp/paper mills, metal rolling lines, pumps in food processing plants and extrusion lines, this trend to upgrade continues today.

|

View more content on PlantServices.com |

Tape provides both insulation and a substrate to which the varnish bonds.

Now, the old question arises. Does the 57% repair/replace threshold still apply?

Tradition says yes, but technology says no. Hidden beneath the hype that followed the new generation of motors was a quiet evolution in the motor repair industry. This, too, was energy focused. Old repair practices and procedures were evaluated and a few were found to degrade a motor’s efficiency.

Of the traditional repair practices that degraded motor efficiency, coil burnout was the biggest offender. Insulating varnish must be treated like paint to remove it, and it was not uncommon to see a motor turned on its end over a bucket of flaming kerosene, the insulation surrounding the coil slowly carbonizing to ash.

It was effective, but this technique put the motor iron in thermal stress, with the hot end approaching 800°F or 900°F and the cooler end at less than half that. When one end was carbonized, the unit was flipped to cook the other end. The extreme temperature gradient caused core losses in the iron and often left the slots distorted. For a motor of 50 hp or greater, the decline in efficiency was about 0.9% to 1.0%. Repeated rewinds made the situation even worse, dropping efficiency as much as 5%.

“Bucket burnout” or other direct-flame methods are no longer considered effective ways to remove damaged coils. Today burnout is done in an oven where temperature zones are controlled to within ±10°F. With temperature peaks limited to 700°F (370°C) and evenly distributed, core iron emerges both mechanically and electrically unchanged. Recently, even safer chemical techniques have shown promise to remove varnish with no danger of thermal damage.

Better balance, stalwart stators

Procedures for restoring the coils have changed, too. Replacements now are wound with overlapping layers of tape insulation that, by itself, has a high dielectric strength (Figure 1). In addition to insulation, this tape also provides a porous surface into which new insulating varnish is applied via vacuum/pressure impregnation (VPI). The porous tape gives “tooth” for adhesion of the new varnish.

The materials used in rewinds have evolved to improve motor performance. VPI is not new, but because it became the standard for infusing rewound motors with varnish, new resins with extreme dielectric strength and mechanical rigidity have been developed. Today’s rewound stator shows little tendency to shift with the same current surges that would have cracked older insulation systems.

The motor repair industry also owes grudging thanks to ISO because it forced a wholesale reevaluation of practices and procedures, particularly on the metrology side of the business. Today, the process of taking measurements and balancing rotating parts is more precise. Even on large rotors and armatures, imbalances are held to less than 0.1 mil or better.

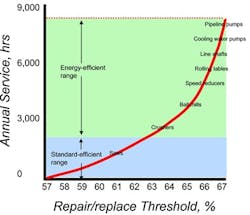

Above is an empirical chart for choosing a new repair/replace threshold. For relatively low operational hours, the curve is relatively flat, but as hours increase above 3,000 per year, it rises exponentially.

Efficiency dividend

What obliterates the old 57% threshold is the startling fact that today’s rewound motor can be more efficient than it was when new. This isn’t always true, but where it occurs, the gain is, typically, a fraction of a percent. There’s enough history with the new rewind technology to prove that this trend is a fact, not a one-off fluke. An EASA/AEMT study put it this way: “…good practice repair methods maintain efficiency to within the range of accuracy that is possible to measure using standard industry test procedures (±0.2%) and may sometimes improve it.” This is true for both energy-efficient and standard motors.

New rewind technology won’t improve a standard motor to the point it can compete with an energy-efficient motor, but it makes rewinds of both types more attractive, particularly if new core plate is included. For energy-efficient motors in relatively good shape - they failed for electrical reasons, not mechanical or thermal reasons - energy efficiency gains of 0.5% have been reported after rewinding. Standard motors sometimes fare even better; it’s possible to see as much as a 1.5% increase in efficiency after a rewind.

What the end user gets for the money is a motor that can improve the plant’s watts-management position. For this reason, today’s repair/replace threshold has shifted from 57% to the mid-60% (Figure 2).

Walt Dryburg is chief engineer at Integrated Power Services, Washington, Pa. Contact him at [email protected] and (724) 225-2900.

Figures: Integrated Power Services.