Drives boost cement plant production capacity by 550,000 tons annually

A $75 million expansion and upgrade of Lone Star Industries' Greencastle, Indiana cement plant did more than boost the facility's production capacity from 750,000 to 1.3 million tons annually. It also introduced a new cement-making process to the United States, which provides the company with both optimized production and operational savings.

"The [new]semi-dry process not only allows us to double production at the Greencastle facility, but provides an environmentally sound alternative to achieving the stringent emission levels imposed by both federal and state regulations," says John Kass, plant manager with Lone Star Industries.

Incorporating the semi-dry process

The Greencastle plant was the company's only U.S. plant to use a wet process. The decision to add a semi-dry process allowed it to retain its wet-feed process, which includes pipelines, pumps and

2-million-gallon slurry tanks. The plant's retrofit included shortening the kiln from 580 to 255 ft., and adding a 322-ft. one-stage preheater tower with an in-line calciner, a dual de-dusting cyclone and a hammermill dryer.

To improve energy efficiency, Lone Star Industries installed 40 variable-frequency drives on critical motors at its Greencastle, Indiana cement plant.

"Slurry now is being atomized in the hammermill dryer and moves through the de-dusting cyclone's calciner and the first-stage cyclone before being fed into the kiln," says Tim Menke, plant production manager. "We are burning two-thirds of the total fuel at the preheater end to dry the slurry,and calcinations of the feed,rather than having the entire heat transfer process occur inside the kiln."

Round-the-clock efficiency

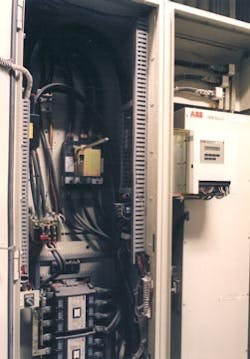

Expanding production capacity ran parallel to the goal of maximizing efficiency and uptime at the 24-hour-a-day operation. Motor and motor drive selection plays a critical role in achieving that objective. As a result, during the last decade, the plant has upgraded many of its electrical motors with more efficient models, says George Glassburn, the plant's electrical superintendent. "We installed 40 variable-frequency drives from ABB on key motors throughout the plant. These are key pieces of equipment that we cannot stand to have fail."

Correct load sizing helped the facility's engineers simplify the variety of motor and drive models needed. "We size motors to the largest horsepower an application requires, and then we slightly oversize the motor," said Ross Tennis, chief electrician at the plant. This strategy allows Lone Star to specify the same motor for a variety of loads within a process.

The same thinking applies to motor drive selection. "The same type of drives are used to control these motors across different functions," says Tennis, who noted that standardization provides multiple benefits, including reduced technician training and spare parts inventory.

A standard AC variable-frequency drive (VFD) powers motors ranging from three to 800 hp in size. Six 150 hp drives control the slurry pumping stations and feed pumps into the kilns, while 600 hp drives power the primary air fan and baghouse cooler exhaust. Smaller motor controllers are used on fuel-feeding applications, such as the alternate fuel pump and agitator, as well as the feeder from the primary rock crusher to the conveyor at the quarry site.

Production increases

The plant upgrade started in June 2000. The kiln now operates three times faster and is powered by a new 900 DC motor and DCS 500 high-performance drive, both from ABB. For the first time, the plant uses medium-voltage technology, for a 5,000 HP ABB drive and motor that powers the new ID fan in the one-stage preheater. With the new semi-dry process and its upgraded power infrastructure, the Greencastle plant now produces some 4,100 tons of product per day, for delivery throughout Indiana and portions of the Midwest.