At times a motor’s capability may be limited to the point where it requires gearing. As servo manufacturers develop more powerful motors that can muscle applications through more complicated moves and produce higher torques and speeds, these motors require gearheads equal to the task.

Interestingly, only about a third of the motion control systems in service use gearing at all. There are, of course, good reasons to do so. Using a gearhead with a servo motor or using an integrated gearmotor can enable the use of a smaller motor, thereby reducing the system size and cost. There are three primary advantages of going with gears, each of which can enable the use of smaller motors and drives and therefore lower total system cost:

Torque multiplication. The gears and number of teeth on each gear create a ratio. If a motor can generate 100 in-lbs of torque, and a 5:1 ratio gear head is attached to its output, the resulting torque will be close to 500 in-lbs.

RPM reduction. When a motor is running at 1,000 rpm and a 5:1 ratio gearhead is attached to it, the speed at the output will be 200 rpm. This speed reduction can improve system performance because many motors do not operate efficiently at very low rpm. For example, consider a stone-grinding mechanism that requires the motor to run at 15 rpm. This slow speed makes turning the grinding wheel difficult because the motor tends to cog. The variable resistance of the stone being ground also hinders its ease of turning. By adding a 100:1 gearhead and letting the motor run at 1,500 rpm, the motor and gear head provides smooth rotation while the gearhead output provides a more constant force with its output rotating at 15 rpm.

Inertia matching. Servo motors generate more torque relative to frame size thanks to lightweight materials, dense copper windings, and high-energy magnets. The result is greater inertial mismatches between servo motors and the loads they are trying to control. The use of a gearhead to better match the inertia of the motor to the inertia of the load can enable the use of a smaller motor and results in a more responsive system that is easier to tune.

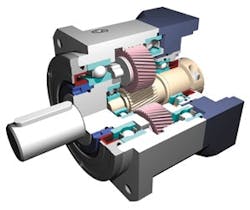

Choosing to go with a separate gearhead assembly (Figure 1) or one that is integrated into a motor (Figure 2) depends on the user’s goals. If compact size is important, it might be best to go with an integrated gearmotor. An assembly that includes both the gearhead and motor in a single housing means that its overall length can be an inch or more shorter than an assembly with a separate gearhead and motor. The design also can be simpler to specify, since you don’t have to worry about a mismatch between gearhead and motor, and you only need a single speed-torque curve to determine if a gearmotor will meet the needs of an application.

The biggest downside of a gearmotor is higher maintenance costs. Maintenance typically requires the entire gearmotor assembly to be removed. In those cases where there is a mistake made during initial design, it is more costly to switch out an entire gearmotor than to just switch out the gearhead.

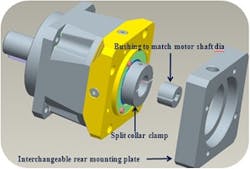

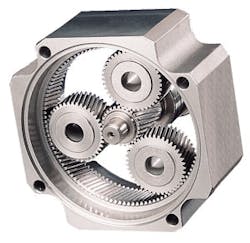

That said, most motion control systems that involve gearing use separate motors and gearhead assemblies, which provides users the flexibility to choose the most appropriate motor and gearhead for the application. Gearheads can typically be mounted to any servo motor: just mount the mating flanges together using standard screws. A split collar mechanism on the input gear secures it to the motor shaft. Figure 3 shows the flexible design typically used by gearhead manufacturers.

Gearhead characteristics determine their appropriate application. Here are some rules of thumb: