Industrial bearing and seal innovations abound

High-performance materials and purposeful designs are helping engineers to optimize seal and bearing decisions. Immediate and visionary objectives are served by improving reliability and durability, simplifying installation and replacement, and supporting green energy and emission goals. The following are examples of some of the many recent developments.

Special-purpose sealing

Innovative seal designs address application challenges such as increasing the performance of industrial robots. Robots must be able to perform repetitive movements with extreme precision for thousands of cycles between maintenance, while potentially exposed to varying media and temperature ranges. Seals from Bal Seal Engineering made from virgin or filled polytetrafluoroethylene (PTFE) help to guard robot parts and systems under these conditions.

“By adjusting jacket geometry, lip force, and other characteristics to strike the right balance of friction and sealing effectiveness, a designer can ensure protection against leakage AND promote smoother, more consistent operation over longer periods,” explains Karina Chavez, an engineer with Bal Seal Engineering. “While it may seem like a minor consideration as compared with overall robot design, seal material choice can also have a significant impact on equipment life and system uptime.”

To facilitate the rise of green hydrogen production, using electrolysis rather than fossil fuels, an advanced sealing solution for electrolyzers from Freudenberg Sealing Technologies bonds sealing material to electrolyzer stack plates in a four-step process. The new gasket-plate units are easy to transport and install and designed to optimize sealing reliability and performance in aggressive conditions, such as pressure and temperature extremes.

By bonding the sealing material directly to the plate through a specialized overmolding process, Freudenberg has been able to eliminate the installation complexity and potential seal damage that results from two separate components, says Robert Lidster, technical director of the Gaskets Division at Freudenberg Sealing Technologies. “The seals and plates are perfectly married,” he adds.

In support of the green energy transition, the TruTech portfolio from Dover Precision Components was recently expanded to include materials engineered to enhance reciprocating compressor sealing durability and performance. In the company’s dedicated materials laboratory, new materials are formulated from high-temperature aromatic polymers such as PTFE and PEEK, with application-appropriate fillers.

This article is part of our monthly Technology Toolbox column. Read more from Sheila Kennedy.

“We’ve developed highly wear-resistant materials for challenging non-lubricated compressor applications and reduced-lubrication materials that increase reliability and equipment life while decreasing maintenance costs,” notes Burak Bekisli, director of materials engineering at Dover Precision Components. TruTech materials are used in Cook Compression sealing components, Inpro/Seal Bearing Isolators, Air Mizer shaft seals, and Waukesha fluid film bearing products.

Beneficial bearing solutions

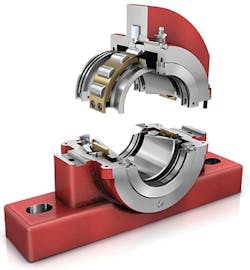

Removing many of the steps involved in replacing traditional solid bearings reduces downtime. The new FAG Split Cylindrical Roller Bearing Housed Assembly from Schaeffler is engineered and manufactured in halves for this purpose. “You basically assemble the bearing components together around the shaft—with little to no disturbance of a machine’s other components and systems,” explains Rob Schoenherr, Schaeffler Americas senior product manager for mounted products.

Industrial bearing and seal innovations abound

By comparison, mounting and dismounting a conventional solid housing and bearing on a shaft typically requires removing parts such as couplings and gears, taking off drives and gearboxes, cutting off the old bearing (or sliding a new one on, if you’re mounting it), and, frequently, stripping the line shafting, Schoenherr explains.

To support carbon neutrality, a new 100% bioplastic heat-resistant cage for rolling bearings is available from NSK. Compared to conventional plastic cages made from fossil fuels, use of the plant-derived material contributes to reducing CO2 emissions. Plastic cages are also lighter, achieve lower friction, and support more advanced, complex shapes than steel cages. Functional evaluation tests of air conditioner fan motor bearings with NSK bioplastic cages versus conventional plastic cages confirmed equivalent performance in noise level, friction, and operating life.

A new CO2 dashboard from SKF helps industry to understand carbon emissions related to the production and use of bearings, including frictional power losses and grease consumption, for different industry applications. When optionally used with SKF’s Bearing Select software tool, users can get a more detailed estimation for single rolling bearings.

“Like SKF, our customers are taking more care when it comes to their carbon footprint. This tool makes an impactful step forward in this regard. We believe that this information will help customers take more data-driven decisions on working towards their CO2 emission targets,” says John Melanson, VP of application engineering at SKF North America.

This story originally appeared in the August 2022 issue of Plant Services. Subscribe to Plant Services here.

About the Author

Sheila Kennedy

CMRP

Sheila Kennedy, CMRP, is a professional freelance writer specializing in industrial and technical topics. She established Additive Communications in 2003 to serve software, technology, and service providers in industries such as manufacturing and utilities, and became a contributing editor and Technology Toolbox columnist for Plant Services in 2004. Prior to Additive Communications, she had 11 years of experience implementing industrial information systems. Kennedy earned her B.S. at Purdue University and her MBA at the University of Phoenix. She can be reached at [email protected] or www.linkedin.com/in/kennedysheila.