Combine HVLS fans and HVAC systems for the best environmental control

The heating, ventilation and air-conditioning (HVAC) industry has long been focused on maximizing the efficiency and performance of air movement and environmental control in all types and sizes of facilities. With rising energy costs, plant managers are looking at these costs more closely, while also considering technology and system designs that can be more easily justified from the perspective of a return on investment.

Perhaps none has been as obvious and attention-grabbing as high-volume/low-speed (HV/LS) ceiling fans. With sizes to 24 ft. in diameter, these fans efficiently circulate air in industrial plants, warehouses and large facilities. When used properly in conjunction with conventional heating and cooling systems, they’re a high-value, cost-effective solution to air movement and better overall environmental control.

HV/LS fans have been available since the late 1980s. One of the first applications was the dairy industry, where they continue to be used for cooling cows to enhance their productivity. The more widespread use of HV/LS fans has become prevalent in the past five years.

HV/LS fans offer specific and often dramatic benefits when used in large facilities. They reduce energy costs, make people more comfortable and productive and, in some applications, help resolve high-humidity or air movement problems.

Expect energy savings

During the heating season, there is often more than a 20°F temperature differential between floor and ceiling at most industrial plants and warehouses because warm, light air rises and cold, heavy air settles. Typically, the air temperature rises between 0.5°F and 1°F warmer for every foot of elevation above the floor. Under these conditions, heating systems must work harder for extended periods to maintain the temperature near the floor, overheating the upper air and wasting both energy and dollars.

To address the issue, HV/LS ceiling fans gently move warm air near the ceiling downward where it’s needed. The air reaches the floor below the fan and moves horizontally several feet above the floor. The air eventually rises to the ceiling where it’s cycled downward again. This mixing effect produces a uniform bulk air temperature, with perhaps a single degree difference from floor to ceiling. This reduces the burden on the heating system.

Conventional high-speed ceiling fans have been used for many years. However, these smaller fans are ineffective for moving warm air from ceiling to floor. The air flow from a typical high-speed ceiling fan spreads out quickly as it moves away from the fan. The result is that little, if any air, reaches the floor.

HV/LS fans also contribute to energy savings in air-conditioned facilities. The light breeze moving across employees’ skin has a cooling effect, so the thermostat setpoint can be raised without compromising employee comfort. The wind from an HV/LS fan allows up to a five-degree increase in thermostat setting with no change in employee comfort. Electric bill savings is 4% for each degree, saving as much as 20% annually.

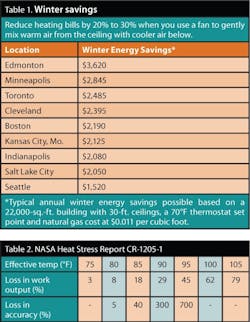

Because HV/LS fans are efficient, their return on initial investment often ranges from six months to two years. Payback on an HV/LS fan varies according to a number of application variables. As shown in Table 1, winter energy savings are substantial. Users can reduce their heating bills by 20% to 30% when using an HV/LS fan to gently mix warm air from the ceiling with cooler air below.

Improve comfort and productivity

A large majority of industrial plants and warehouse facilities aren’t air-conditioned. During the summer months, this can make for an uncomfortable environment, resulting in a loss of productivity and employee morale. Companies often try to keep employees comfortable by any means, whether it’s with cold beverages or frozen fruit bars.

A NASA study (Table 2) found that as effective temperature rises, work output and accuracy plummet. The study also found that moving a steady, light breeze across people’s bodies produces an evaporative cooling effect that reduces the effective temperature by 10°F to 12°F. The effective temperature corresponding to 84°F and an air speed of 3 mph is 73°F. Air moving faster than 5 mph provides no additional cooling effect.

Whether it’s the heating or cooling season, HV/LS fans are preferred over high-speed ceiling fans or floor fans. The reason is that HV/LS fans move more air at the right speed, get air where it’s needed and do so with little energy consumption. Unlike high-speed ceiling fans, technically advanced HV/LS fans move large volumes of air over an area as much as seven times to eleven times their diameter. A single HV/LS fan can replace as many as 10 to 20 floor fans.

High-speed floor fans have several disadvantages when compared to HV/LS ceiling fans. Specifically, they produce a blast of wind in a relatively small area; they’re noisy, they can be more disruptive and they use much more energy. In addition, having multiple floor fans can increase clutter and the chance of mishaps involving equipment and electrical cords. Lastly, the localized, high wind speed they produce might contribute to employee fatigue.

Handle humidity and stagnant air

In addition to energy savings and improved employee comfort, HV/LS fans have proved to be effective in applications in which excessive moisture and slow-drying processes occur. Examples include brick manufacturing, carpet cleaning, painting, maintaining cardboard packaging integrity and drying stored metals to prevent rusting. HV/LS fans can reduce floor sweat caused by a differential in surface and air temperature.

HV/LS fans also are a worthwhile consideration for buildings in which stagnant air fosters an unhealthy environment. HV/LS fans improve air quality through better air circulation. The fans often are the most cost-effective way to accomplish this in large, open spaces.

Plan for performance

There are a number of factors to consider when deciding how and when to use HV/LS fans. They include obstructions such as pallet racks, machinery and product staging; personnel work areas; and overall building layout, to name a few. Larger diameter fans will move air further down rack aisles and over obstructions. Smaller diameter fans can be most effective in specific work areas or where installation space is limited. Fan suppliers can help configure an array of fans, determining the number, size and locations that will provide the maximum benefit for the investment. They also can offer turnkey installation if on-site resources are not available.

The basic concepts are similar across HV/LS fan manufacturers, but fan design and performance are key factors to consider. There are significant differences among manufacturers, including the shape and number of blades, blade tilt, hub construction, blade-to-hub connection and safety features. The performance of different designs varies in the uniformity of air movement directly below the fan, as well as the height and reach of air movement outward from the fan’s perimeter. Other important considerations include ease of installation, local representative support, trial program availability and warranties.

New kid on the block

The old saying, “There’s a new kid on the block,” could describe how the use of HV/LS fans has gained attention in the HVAC world as a practical and affordable solution to improved air movement and better environmental control. These types of fans are now recognized as a valuable supplement to help facility managers control energy costs and improve employee comfort and productivity. To take full advantage of this truly “big” opportunity, make a careful analysis of each application, as well as each HV/LS fan design.

Dan Anderson is product manager of control solutions at Rite-Hite Corp., Milwaukee. Contact him at [email protected] and (414) 973-3605.