In brief:

- An understanding of the load vs. efficiency relationship is a guide for better decisions about boiler operation.

- The oxygen content in turbine exhaust gases is sufficient to support the combustion needed for a downstream waste heat boiler.

- The heat recovery steam generator uses about 8% to 10% less fuel input to produce the same amount of steam as a package boiler.

Figure 1. Typical D-type package boiler is ready to be installed.

Many process plants, refineries and chemical plants have package boilers (Figure 1) and supplementary gas-fired heat recovery steam generator (HRSG) (Figure 2). Without a clear understanding of the thermal performance characteristics of these two types of steam generators, plant engineers often don’t assign loads to them judiciously so that the total plant steam is generated most efficiently.

If you know the characteristics of typical natural-gas-fired package boilers and gas-turbine HRSGs used in process or cogeneration plants, you can generate steam optimally and minimize fuel bills. The knowledge also will help when planning which type of HRSGs should be bought, whether unfired, supplementary fired or furnace fired.

Figure 2. A typical furnace-fired HRSG has a water-cooled membrane wall, O-type boiler with furnace, superheater, evaporator and economizer.

Steam generator performance

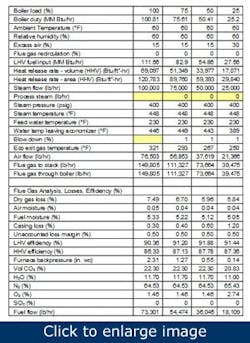

Table 1. Boiler performance varies as a function of the load.

The first step is to understand the load-versus-efficiency characteristics of a typical package boiler. Table 1 shows performance variation as a function of load. The boiler with an economizer generates 100,000 lb/h of saturated steam at 400 psig using natural gas. At 100% load, the exit gas temperature is 320 °F. Excess air is 15%. The various losses (per ASME PTC 4.1) are shown along with the efficiency.

The efficiency variation isn’t much with load. The casing loss is a function of casing temperature, wind and ambient conditions and doesn’t change with load. Hence, efficiency as a percentage of boiler duty will be smaller at higher loads, and vice versa. The flue gas losses on the other hand will be greater at greater loads as the exit gas temperature is greater at greater loads and decreases as the load decreases.

The combination gives a somewhat flat or parabolic performance curve (Figure 3). The efficiency on a lower heating value (LHV) basis increases slightly from 91.44% at 25% load to about 60% load and then tapers off. To determine burner duty, divide the boiler duty by the efficiency. Using a performance sheet obtained from a boiler supplier, one can get an idea of the fuel consumption at any load.

Figure 3. Boiler performance as a function of load shows a decline at conditions above some load point.

HRSG performance

Heat recovery steam generators behind gas turbines are either unfired or fired. In the fired category, depending on the firing temperature, HRSGs are classified as supplementary fired or furnace fired. Typically, turbine exhaust gases have 14% to 15% by volume of oxygen in the exhaust, which can be used as combustion air. Simply by adding fuel to a burner located in the gas stream, one can increase the exhaust gas temperature from the typical 900 °F to 1050 °F to as high as 2,500 °F to 3,000 °F, depending on boiler design.

When the firing temperature is less than 1,600 °F, use an HRSG with insulated casing. This resembles an unfired unit. However, when firing temperature gets higher, a water-cooled membrane wall design is preferred. The water-cooled enclosure permits you to fire to as high as 3,000 °F. Note that in package boilers, the flame temperature is around 3,200 °F. This type of HRSG is called a furnace-fired unit and is available as shop-assembled units that handle as much as 400,000 lb/h exhaust gas flow. When gas flows are higher, field-erected units might be necessary because of shipping concerns.

In the unfired mode, the HRSG generates 25,000 lb/h steam and, depending on firing temperature, can generate as much as 100,000 lb/h. The firing temperature at full load is about 2,500 °F. The burner is mounted in the front wall of a water-cooled enclosure with a furnace section followed by evaporator tubes. An economizer is required to improve the efficiency. Table 2 gives HRSG performance at various loads.

Table 2. HRSG performance is a function of load

A fired HRSG is more efficient than an unfired HRSG. This is because gas turbines have a more-or-less constant exhaust gas flow and the steam generation is varied by adding the fuel. This is possible because the excess oxygen in typical turbine exhaust gases is 15%. Hence, no additional air is required. We’re simply reducing the excess air in the exhaust gases. Also, Table 2 shows that with an evaporator-economizer single-pressure unit, the economizer exit gas temperature decreases as the firing temperature increases.

[pullquote]

This characteristic is opposite to that of a package boiler. The reason is the bigger heat sink at the economizer at higher loads in the form of increased water flow. Unlike in a steam generator (Table 1), the exhaust gas flow is nearly constant in an HRSG, and we’re only varying the firing temperature to generate more steam. Hence, the fuel utilization is better when generating more steam. The heat losses are less at higher loads. If we consider the additional boiler duty and the additional fuel input for this additional steam generation, the HRSG comes out a winner hands down.

At 50% load, the steam generation is 50,000 lb/hr, and additional boiler duty is 24.9 million Btu/hr compared to the unfired condition. However, we are consuming only about 24 million Btu/hr (LHV basis) fuel to generate this steam. This implies that fuel efficiency is more than 100%. If we generate the same additional 25,000 lb/hr steam in a steam generator, the additional fuel input (Table 1) is about 27.2 million Btu/hr on LHV basis. Another way to look at the efficiency of both boiler types is this: The HRSG generates an additional 75,000 lb/hr of steam with a fuel input of only 75.6 million Btu/hr (subtract the fuel input at 100,000 lb/hr steam from the unfired case steam generation). The package boiler, on the other hand, requires 84 million MM Btu/hr (111.6-27.56). Hence, the HRSG can produce steam with about 8% to 10% less fuel input.

Optimal operation mode

Plant engineers might evaluate fuel input vs. steam demand data as shown in Table 3. For various combinations of steam flows from the boiler and HRSG, the fuel the boiler and HRSG require are added and the total shown. The best fuel consumption occurs when the HRSG is operated at or near full load.

Table 3. Total steam generation is a function of fuel input.

For example, a steam demand of 100,000 lb/hr can be achieved in several ways. The total fuel consumption is computed, and a prudent decision can be made. Operating the HRSG in the maximum fired condition gives the lowest fuel consumption. However, if this isn’t possible, you’ll need to look into the next best option. You can develop similar tables for your own plant to determine if fuel consumption can be reduced.

With multiple boilers or HRSGs, this study becomes more challenging but worth the effort. When planning for future cogeneration projects, keep the fired HRSG in mind. Get data such as steam generation vs. fuel consumption from boiler and HRSG suppliers before buying.

Figure 4. Exit gas temperature and fuel input as function of load for a typical HRSG. Exit gas temperature decreases with load, while fuel input increases. Fuel units are MM Btu/hr LHV.

Viswanathan Ganapathy is a boiler consultant in India who works with Cleaver-Brooks (www.cleaver-brooks.com). He has authored five books, including “Industrial Boilers and HRSGs.” Contact him at [email protected].