Advanced control schemes can't produce optimum results unless the control valves operate properly. Instrument technicians must understand these final control elements as well as their diagnostic software to ensure the valves in the plant operate as the system designers intended.

Renewed interest in the performance of control valves is emerging, partly as a result of numerous plant audits that indicate roughly one-third of installed control valves are operating at substandard levels. Even though properly operating control valves are essential to overall plant efficiency and product quality, maintenance personnel frequently don't recognize the signs of poor performance. The basics of control valve design and operation must be well understood for end-users to reap the benefits of improved valve operation.

Basic types of control valves

The most common and versatile types of control valves are sliding-stem globe and angle valves (see Figure 1). Their popularity derives from rugged construction and the many options available that make them suitable for a variety of process applications, including severe service. For example, sliding stem valves typically are available with options that satisfy a range of requirements for ANSI Class pressure-temperature ratings, shutoff capability, size, temperature compatibility and flow characteristics.

Figure 1. Sliding-stem globe and angle control valves.

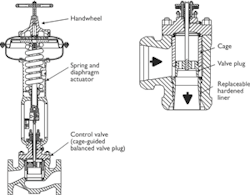

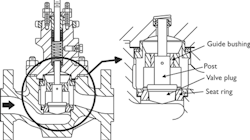

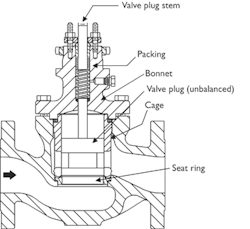

The first distinction among globe and angle valves is whether the valve is post- or cage-guided. In post-guided valves (see Figure 2), the closure member is guided by a bushing surrounding either the valve stem or a portion of the valve plug. In cage-guided valves (see Figure 3), a close-fitting, cylindrical cage guides the plug. Cage guiding provides a comparatively larger guiding surface, which helps minimize vibrations, improve valve plug stability and increase pressure drop ratings.

Figure 2. Post-guided valve.

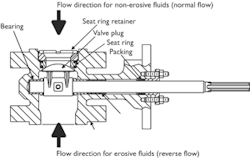

Rotary-shaft control valves are available in several different types, each characterized by the geometry of the closure member (disk, ball, ball segment or plug). Compared to sliding-stem valves, rotary-shaft valves typically have limited pressure drop ratings, are less expensive, have greater rangeability and provide greater flow capacity for a given valve size. Rotary valves typically are selected to provide unique features, such as high capacity (full-bore ball valve), shear on closing action (ball segment valve), low cost (standard butterfly) or resistance to erosion damage (eccentric rotary plug shown in Figure 4). In general, rotary-shaft valves offer fewer severe service options (trim options to attenuate control valve noise, eliminate cavitation and provide other desirable characteristics).

Figure 3. Cage-guided valve.

Selection and sizing

Control valve selection is based on the process fluid to be handled and a number of performance objectives. Required sizing parameters include specific gravity, pressures at the valve inlet and outlet, pressure drop across the valve, fluid temperature at the valve inlet, flow rate and vapor pressure. Other vital information includes the desired response time, process gain characteristics and the potential for cavitation or flashing.

Achieving complete valve shutoff is important in many applications to prevent leakage that either could contaminate a process fluid or result in product loss. Tight shutoff also prevents erosion damage that could occur if a high-velocity stream leaked across seating surfaces.

Many control valves are oversized as a result of inaccurate information and safety margins added by each individual or group that participates in the sizing procedure. Oversized valves are a problem for three reasons.

First, the valve operation may become unstable because it never opens very far from the fully closed position. Process gain is generally high when the valve is throttling near its seat. The combined valve and process gains may be too high to maintain stable operation at low lifts. Second, excessive seat wear may result from high velocity flows between the closure member and the seating surface. Third, the design flow characteristic may not be achieved, resulting in controller tuning problems.

Valve manufacturers and vendors usually use specialists in fluid thermodynamics who can provide system designers with state-of-the-art solutions to unusual sizing situations.

Figure 4. Eccentric rotary plug valve.

Actuation

A properly selected and sized control valve can deliver optimum performance only when the plug, disk, ball or ball segment positions itself properly in response to the control signal. Closure member positioning is a function of actuator performance and the instrumentation that provides loading pressure to the actuator. There are three relevant factors to consider.

Force at the closed position: For globe and angle valves, the actuator must provide sufficient force (or thrust) to achieve the specified ANSI Class shutoff. For rotary-shaft valves, the actuator must provide sufficient torque to move the closure member into and out of the seat.

Actuator stiffness: To maintain valve plug stability, the actuator must offer sufficient resistance to fluid buffeting forces by means of a mechanical spring or air spring effect.

Fail mode: This defines the position to which the closure member moves if the compressed air supply is lost.

Some controversy exists over the relative merits and limitations of piston actuators versus spring-and-diaphragm actuators. Both devices are useful, and each has a place in process control.

Spring-and-diaphragm actuators are simple and reliable, and they can be used in most control applications. One of their major advantages is the built-in spring fail action (inherent fail mode) that provides full shutoff force in the event supply pressure is lost.

Positioners

A valve positioner ensures the actual valve stem position matches that which the control signal is trying to achieve. Even the best control valves can't achieve peak performance without a high-performance positioner. In a competitive production environment, positioners have achieved the status of essential automation instrumentation.

They're frequently used to overcome high valve friction and reduce the resulting deadband and hysteresis, which provides more accurate control. A positioner must be used with a double-acting piston actuator (with or without springs) to provide throttling control.

Positioners typically are used to increase actuator force in the travel stop positions. The extra force is especially useful for rotary valves because of their substantial seal friction.

During the past several years, considerable interest has developed over "smart" field-mounted instruments and the protocols that allow communication among them, the control system host and other devices on the control network. Smart field-mounted instruments deliver a number of useful features that give technicians the ability to configure, calibrate and troubleshoot instruments and control valves from remote locations. Advanced diagnostic features allow users to implement predictive maintenance procedures by scanning large numbers of devices automatically and identifying those that most need service. Systems that support smart devices make possible advances in asset management, generation of work orders, alerts and alarms in control systems, and in the not too distant future, instant messaging of valve alerts and failures to maintenance department pagers and cell phones.

The overlooked technology

Process engineers have long looked upon control valves as low-tech "iron" that simply obeys instructions. Yet control valves are actually among the most complex field devices, required to perform rigorous tasks repeatedly, often under severe service conditions. If they're not properly selected, installed and maintained, control valves can cause drastic reductions in process efficiency.

Where a concerted effort has been made to understand the performance of these final control elements, increases in throughput and profitability are typical. Points to remember include:

- Process variability decreases when control valves are properly installed, calibrated and maintained.

- Ensuring control valves respond quickly and accurately to control signals reduces process variability.

- Minimizing process variability improves plant performance.

How can you take advantage of such benefits? The answer is education. Process engineers and instrument technicians who truly understand control valves, including recent advances in valve and instrumentation technology, are able to install and calibrate new or rebuilt valves correctly, troubleshoot problems more effectively and make beneficial adjustments without removing valves from operation. Well-trained personnel implement less costly maintenance programs that result in high efficiency with a minimum of unexpected shutdowns. They do it through careful monitoring of the condition of every control valve in the plant and selecting for immediate repair or replacement only those valves whose early failure or loss of performance is a distinct possibility.

Steve Hagen, Senior Instructor at Emerson Learning Solutions, Marshalltown, Iowa, can be reached at http://www.emersonprocess.com/education and (641) 754-3771.