Buzzwords such as sustainability, green and environmental responsibility are being touted more than ever by those who own and operate industrial manufacturing plants. Why? Being perceived by customers and prospects as sustainable, green and environmentally responsible can translate to marketplace advantages. A number of factors drive that mindset, including legislation such as the federal Energy Policy Act of 2005 (EPAct 2005), which is rewarding energy-efficient installations with tax incentives through the end of 2013.

Another driver that’s gaining prominence is the Leadership in Energy and Environmental Design (LEED) Green Building Rating System, administered by the U.S. Green Building Council. LEED is a leading-edge system for designing, constructing, operating and certifying the greenest, most environmentally friendly buildings, including industrial facilities. Like every LEED certification program, LEED Version 31 for New Construction and Major Renovations (LEED-NC), released in April 2009, has various prerequisites and requires accruing supplemental credit points in seven areas.

[pullquote]A key focus of any LEED-NC industrial project should be the electrical loads dedicated to lighting, which can account for as much as 30% or more of a facility’s electric bill. Obviously, lighting supports production and safety in an industrial setting. But, well thought out lighting control can help reduce and better manage electrical consumption while still maintaining adequately lit working conditions.

Facility owners and managers with an astute understanding of available technologies are best positioned to achieve both goals en route to achieving LEED-NC certification for their new or substantially renovated plant.

LEED-NC and lighting control

LEED was developed to improve the environment, occupant health and return on investment. It reduces the effects of natural resource consumption and minimizes the strain on utilities that provide energy to an industrial facility, including electricity. But LEED also promotes whole-building, integrated design processes and provides a measurement standard for sustainable, environmentally friendly facilities, while simultaneously preventing greenwashing, those exaggerated energy-efficiency claims.

LEED offers several certification programs for commercial buildings including industrial facilities. LEED-NC should be considered when a facility is either new or undergoing a significant HVAC, envelope or interior upgrade. Conversely, LEED for Existing Buildings: Operations and Maintenance (LEED-EB: O&M) is used if a project focuses on a facility’s operations and maintenance and isn’t undergoing a major renovation.

You can achieve LEED-NC certification by meeting prerequisites and accruing supplemental credit points in several areas:

- Sustainable sites (one prerequisite, 26 possible credit points)

- Water efficiency (one prerequisite, 10 possible credit points)

- Energy and atmosphere (three prerequisites, 35 possible credit points)

- Materials and resources (one prerequisite, 14 possible credit points)

- Indoor environmental quality (two prerequisites, 15 possible credit points)

- Innovation and design process (six possible credit points)

- Regional priority (four possible credit points)

Credit points add up to LEED-NC certification levels. The Base-level certification requires 40 to 49 points, the Silver needs 50 to 59 points, the Gold requires 60 to 79 points and the Platinum needs 80 points or more.

Thus, owners and managers of new industrial facilities or those undergoing substantial renovation need to determine with other project participants, especially the consulting electrical engineer, which LEED-NC certification level can be achieved under the available budget. Because lighting control permeates many aspects of a LEED-NC project, it can help maximize potential credit points at a lower cost than other solutions, providing the owner or manager a better opportunity to achieve a desired certification level.

Plus, lighting control technologies can be installed relatively seamlessly and offer a typical payback period of two years or less. But, most importantly, lighting control is required under the Energy and Atmosphere component, which uses the ANSI/ASHRAE/IESNA Standard 90.1-2007 Energy Standard for Buildings Except Low-Rise Residential Buildings as part of its energy efficiency requirement.

What follows is a primer on lighting control-related prerequisites and credit points that can be earned for LEED-NC certification, along with information on technological advances that can help meet those needs. Space doesn’t permit delving deeply into the nuances of the LEED programs; consulting the U.S. Green Building Council Web site (www.usgbc.org) or making contact with a LEED-accredited professional are recommended.

Energy and atmosphere

The intent of this section is to verify a project’s energy-related systems are installed and calibrated to perform according to the owner’s project requirements, basis of design and construction documents.

Lighting control figures prominently in several LEED-NC certification components, but perhaps the most important is Energy and Atmosphere. The intent of the second of its three prerequisites is “to establish the minimum level of energy efficiency for the proposed building systems to reduce environmental and economic impacts associated with excessive energy use.” To that end, it provides several options, including a whole-building energy simulation that establishes a 10% improvement in a new building’s proposed energy performance, or a 5% improvement for a substantially renovated building, compared with ASHRAE/IESNA 90.1-2007’s baseline performance rating. ASHRAE/IESNA 90.1-2007 requires lighting control to achieve that baseline rating, including automatic shutoff and controls for individual selected interior spaces and exterior lighting.

Automatic shutoff: According to ASHRAE/IESNA 90.1-2007, automatic shut-off options are required for interior lighting in buildings that are larger than 5,000 sq. ft., and must be controlled using a time-of-day operated control device, occupancy sensing or a signal from another control or an alarm system.

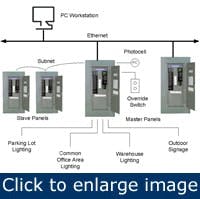

Schedule-based lighting control, based on a controller in an intelligent lighting control panelboard, lends itself to larger manufacturing spaces. Here, Web-enabled lighting control systems have begun to gain prominence because of the convenience they offer. Available systems allow facility managers to set a lighting schedule and make changes to any area within it via a standard Web browser on a desktop PC or laptop, instead of a dedicated workstation running proprietary software. Plus, such systems can contour the lighting to the needs of specific areas, from multiple manufacturing zones to office areas to shipping and receiving.

Occupancy sensors manage lighting where occupancy isn’t predictable, such as individual offices, restrooms and break rooms. The sensors reduce wasted energy by shutting off lights within 30 minutes of the last occupant leaving the area. Occupancy sensors typically use either passive infrared (PIR) or ultrasonic technologies, or a combination to avoid the false turn-offs that were characteristic of earlier designs.

Finally, many schedule-based lighting control systems also can receive signals from other control systems, perhaps a security system. For example, a manager might use a card reader to enter the building when it’s closed; once the card is read, the security system sends a signal to the lighting zone where the manager’s office is located, turning on the lights in that zone for a pre-set period.

Space controls: Lunch rooms, break rooms and conference rooms must have a lighting control device, often an occupancy sensor, that turns lights off within 30 minutes of occupants vacating a space. In other spaces, a control device must activate either manually or automatically by sensing occupants and be capable of overriding a time-of-day schedule for no more than four hours.

Exterior lighting control: Lighting control must be capable of turning off parking lot or perimeter lighting when sufficient daylight is available or when lighting isn’t required during overnight hours. Lighting designated for non-dusk-to-dawn operation is typically controlled either by photocells or by an astronomic time switch inside the controller of an intelligent lighting control panel board.

As an extension of Energy and Atmosphere Prerequisite 2, credit points can be accumulated by increasing energy efficiency from the baseline established by ASHRAE/IESNA 90.1-2007. For example, a new construction that is demonstrated to be 12% more energy efficient than the baseline earns one credit point, as does a major renovation that is demonstrated to be 8% more energy efficient. A new construction that is demonstrated to be 48% more energy efficient, or a major renovation that is 44% more energy efficient, earns 19 credit points, the highest amount awarded.

Indoor environmental quality

This section establishes the minimum indoor air quality (IAQ) performance to enhance indoor air quality in buildings, thus contributing to occupant comfort. The Indoor Environmental Quality component of LEED-NC, Credit 6.1: Controllability of Systems—Lighting offers one credit point for providing individual control for a minimum of 90% of occupants to meet both individual preferences and task needs.

Automatic controls such as dimming and task lighting should be considered when developing the overall lighting design plan and building energy action plan. As many as two points can be gained through Credit 8.1: Daylight and Views—Daylight and Credit 8.2: Daylight and Views—Views. Sensors that turn artificial lights off when daylight has reached a predetermined threshold, and then back on again when daylight wanes, can be used.

Innovation and design

This provides an opportunity to achieve exceptional performance above the requirements set by the LEED Green Building Rating System, or performance not specifically addressed by the system. As many as five credit points can be earned under the Innovation and Design component by achieving exemplary performance beyond LEED-NC requirements but not specifically addressed by it.

One point might be offered for each innovation; those that might qualify include:

- Bilevel and motion-based lighting control for parking lots maintains a lower level of lighting for safety and security, with motion sensors activating a higher lighting level in an area.

- Using lighting control in conjunction with demand response systems means a schedule-based lighting control system can shed lighting loads, based on a signal either from the facility manager or the building automation system.

- Some schedule-based lighting control systems can monitor systems for relamping. Runtime counters can track the number of hours a lighting system burns and then notify the facility manager when a group re-lamping project should be scheduled.

Getting started

For more information on LEED 2009, visit:

U.S. Green Building Council

|

Lighting control should be a major part of any industrial facility LEED-NC project because of the number of certification credit points that can be accrued. Of course, while LEED certification can be prestigious and the energy and cost savings significant, it’s important to ensure lighting control is implemented properly, so neither productivity nor safety is compromised.

That’s why the best rule of thumb for industrial facility owners and managers who are contemplating LEED-NC certification is to be armed with as much information as possible about anticipated workflow at their new or substantially renovated facility. This information helps a consulting engineer make the most astute lighting control product specifications that maximize credit points. It’s also a good idea to interface with a trusted supplier of multiple lighting control technologies to better understand your options and how they might be applied.

Scott Jordan is lighting control product manager at Schneider Electric’s North American Operating Division, and is based in LaVergne, Tenn. Contact him at [email protected].