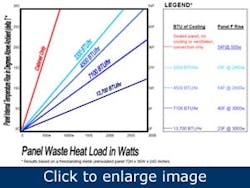

If the heat load within a control enclosure is beyond the cabinet’s capacity for natural convection cooling, heat buildup will cause problems or even complete failure. This chart shows temperature differential over ambient conditions as a function of waste heat generation for different cooling capacities.

Uninsulated NEMA 12 and higher metal panels dissipate heat via natural convection, which occurs primarily along vertical walls, not from the top as intuition might lead you to expect. Therefore, a simple cooling solution for low heat loads is to place equipment in oversized panels that maximize vertical height over width and depth as much as possible.

As the chart indicates, in ideal conditions a 72-in. x 36-in. x 24-in. freestanding uninsulated metal panel with no sources of high heat such as transformers or ovens attached or nearby can dissipate nearly 500 watts of waste heat with only a 15°C/27°F rise in panel temperature above ambient via unassisted, natural convection cooling.

Those ideal conditions require that the ambient temperature never rise above 77°F (25°C) to maintain a conservative 104°F (40°C) panel or no greater than 95°F (35°C) for an allowable 122°F (50°C) panel air temperature. But few environments are that ideal, and most heat loads are far larger than 500 watts.

If the required internal panel temperature is below the peak ambient the panel will experience, then a below-ambient cooling solution, such as air-to-water heat exchangers, compressed air, or air conditioning is a must. If there’s a sufficient delta-T between the panel requirement and the ambient air temperature, a heat pipe-based heat exchanger often is the most cost-effective solution.

Doug Wilson is applications engineer at Noren Products Inc., Menlo Park, Calif. Contact him at [email protected] and (650) 322-9500 x 239