One of the most critical automatic safety devices in a steam system is the safety valve. It protects lives, equipment and property from potentially dangerous levels of temperature and forces caused by excessive steam system pressure.

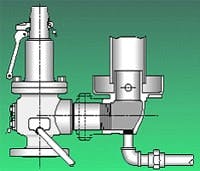

Codes and insurers require safety valves be part of the steam system (Figure 1). Therefore, it’s important to have well documented up-to-date records for the plant’s steam system safety valves. Develop a database containing the facility’s relevant safety device information using readily available technology. Update the database periodically, depending on plant standards, insurance company recommendations, and the local, state, or federal government requirements.

The code that establishes the requirements for safety valves is governed by the American Society of Mechanical Engineers (ASME). Through its committees, ASME has published and continues to update the Boiler and Pressure Vessel codes for safety valves. It’s the responsibility of plant personnel, primarily the steam team, to know which codes apply to the different parts of the steam system. In the United States, major considerations for safety valves are proper sizing and correct installation.

Sizing guidelines for safety valves

A partial listing of sizing and installation highlights is listed below:

Figure 1. This schematic shows a proper safety valve installation with its drains and drip pan elbow.

Installation

This is the second key element of successful safety valve operation. Some guidelines to consider include:

Figure 2. A proper safety valve installation with a vertical orientation, drip pan elbow and drain lines off the safety valve and drip pan.

Figure 3. This safety valve is not installed correctly because it’s not oriented vertically. Safety valves are tested and set at the manufacturer or assembler; if mounted off of the vertical position, this could or will change the set point.

Vent piping

The guidelines that apply to vents are:

Figure 4. The vent pipe size must be at least as large as the valve outlet to prevent excessive backpressure from affecting the valve performance.

The proper selection, installation and use of safety valves require a complete understanding of ASME code and any additional requirements insurance companies or local jurisdictional authorities adopted.

Kelly Paffel is the technical manager at Inveno Engineering, LLC. Mr. Paffel is a recognized worldwide authority in industrial steam systems. He has has 35 years of experience in steam, compressed air systems and power operations. Mr. Paffel has achieved Steam System Level V certification in Steam Systems and is also is also a member of the Department of Energy’s (DOE) Steam Best Practices Committee and Steam Technical Committee.

Images courtesy of Swagelok Company