Start your industrial efficiency measures with lighting

Industrial facilities have more opportunities than ever to increase energy efficiency and reduce energy consumption — from refrigeration, HVAC and lighting to materials handling, water usage and recycling. Technological innovation makes the decision to adopt improved energy-efficient solutions and strategies a no-brainer. However, facility managers and sustainability executives still face funding obstacles and challenges that can form barriers to adopting these new measures.

Finding practical approaches to funding energy efficiency and ensuring a successful program shouldn’t be a daunting process. Especially when maintaining the status quo puts your facility and organization at risk or competitive disadvantage because of rising or unpredictable costs. The top-of-mind questions that usually arise when considering a project include:

- Where do I start — which areas can benefit most quickly from energy-efficient solutions?

- How do I fund the solutions — from acquisition to installation to maintenance?

- What will be the payback, and how can I measure ROI and TCO?

- How do I know if my decisions will achieve the projected savings?

Following are some proven strategies for tackling those questions and driving down energy consumption.

Lighting first

Start with lighting to free up funds for other projects. According to AMR Research’s 2010 report, “Illuminating the Sustainability Challenge: Delivering Sustainable Business Strategies through Disruptive Innovation and Technology,” lighting remains the largest user of electricity in buildings. In warehouses and industrial facilities, lighting typically costs $1/sf/year, but reducing that number frees up funds that can defray other energy-efficiency projects. Additionally, because it’s relatively easy to retrofit lighting fixtures, it’s an easy first program to take on.

[pullquote]Lighting is essential to any facility to provide a safe and comfortable workplace. However, legacy lighting fixtures are inefficient, expensive to maintain and basically “dumb.” With smart technologies and the evolution of highly controllable LEDs for high-intensity applications, you can achieve massive reductions in energy use and costs — as much as 90%. Intelligent lighting systems provide more light and only where and when it’s needed. They also reduce maintenance and improve operational control to enable new levels of sustainability.

What kind of savings does that translate into? A 90% decrease in energy use in a 250,000-sf facility reduces lighting costs from $250,000 to $25,000, enabling a large percentage of the project cost to be funded through savings.

How do you know if your lighting needs to be updated? Analyze your electric bill to ascertain how much lighting is costing you. Then ask yourself some basic questions:

- Is it bright enough? Or do you have lamps out that need replacing or diminished fixture outputs?

- Can you control lighting easily to maximize efficiency when no one is in an area of the facility?

- What kind of data are you able to retrieve to measure and manage electrical energy usage?

- Does your lighting give off excess heat, forcing your chiller to work harder to keep things refrigerated?

- Does the lighting require warm-up time before generating full output?

- Are you spending significant time and money on lighting maintenance, including ballast and bulb replacement?

The findings will help drive discussions on funding lighting as the first step on much improved energy efficiency.

Funding options

You have several options available to finance energy-efficient solutions — from capital expense to leasing to shared savings models.

Capital expense — For many organizations with low capital costs, this can be an appealing strategy, especially if the expected payback period on the investment is rapid.

Leasing — Another approach is leasing new equipment, which has a couple of variants. An operating lease requires that the equipment be returned at the end of the lease, or that an agreement is reached to extend the lease or be purchased at fair market value. A capital lease is structured so the equipment is paid off in installments and, at term end, the lessee owns the energy-efficient solution. The advantage is that a capital lease doesn’t involve any — or very little — capital outlay.

Energy service companies (ESCOs) are potential lessors. The agreement might involve either sharing in the savings — for example, the ESCO buys the new lighting and then shares part of the project savings — or the ESCO determines a guaranteed savings for the contracting organization and keeps the rest.

Performance contracting — Typically involving an ESCO or other energy-efficiency provider, performance contracts assign a third party to manage a group of efficiency projects from end to end, including financing. The advantage is no upfront costs or debt for the balance sheet. The disadvantage can be losing a substantial portion of the savings to the ESCO. This approach might be best considered if you are looking at a large and complex project and have a limited ability to spend capital budget or take on debt.

Rebates and incentives

Utility companies in most areas offer compelling rebates and incentives that can defray a significant portion of your energy-efficiency projects — as much as 50% of the costs. Why? Reducing load to accommodate growing demand postpones the need to build additional capacity — an expensive prospect. An essential first step for any project is to check with your local utility to understand the options available for a given project type and any requirements around the incentive (product or measurement-and-verification).

In addition, the 2009 American Recovery and Reinvestment Act introduced numerous opportunities at the federal and state levels for promoting energy-efficiency projects through the U.S. Department of Energy. This includes specific program grants for industrial energy-efficiency programs. Each state has its own programs to be investigated for funding assistance and incentives, such as the New York State Research and Development Authority (NYSERDA).

Useful resources you might want to consult are the U.S. Department of Energy’s database of State Incentives for Renewables and Efficiencies (DSIRE) and the American Council for an Energy-Efficient Economy.

Making the business case

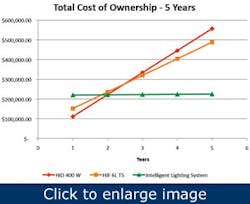

When considering any project, the rubber hits the road when the numbers hit the spreadsheet. The essential numbers — itemized upfront costs to acquire and install new equipment, rebates, tax credits, and anticipated energy and maintenance savings — need to be gathered. Then the number crunching begins in earnest. The most common question is how quickly the energy and maintenance savings will offset the initial investment. The two most prevalent approaches to consider are payback and total cost of ownership (Figure 1).

Figure 1. This analysis makes a series of assumptions. First, 200 existing HID fixtures are being replaced with HIF or ILS in a 1-for-1 retrofit. The HID and HIF include relamping/maintenance costs whereas ILS doesn’t have relamping or maintenance. Estimated HVAC savings is included for HIF and ILS, energy incentives are excluded in the calculations. The utility cost is $0.134/kWh.

Payback — This is the analysis most people focus on when considering a purchase. Divide the upfront costs by the annual energy savings, with an eye toward when the anticipated savings cover the initial purchase price (time horizon). But this analysis doesn’t capture the whole story and can skew toward a short-term solution that will deliver smaller energy savings over time.

Total cost of ownership (TCO) is the most comprehensive approach; it captures every variable across the project’s lifetime. TCO is determined by analyzing the total costs — installation, operation and maintenance — less the annual energy, maintenance and cooling savings. For example, when upgrading lighting, determining how often lights will be off because of a lack of activity will be a key factor in generating chiller savings through reduction of lamp heat generation.

Choosing a solution with smaller upfront costs might seem appealing, but if the energy savings are smaller, they increase the TCO, sometimes significantly. If a proposed project has greater upfront costs, but much greater annual energy savings, the savings will accumulate continuously over time, and the TCO will be much more advantageous. The goal is to minimize TCO while staying above the minimum corporate ROI threshold.

Snapshot energy efficiency isn’t enough Leadership in energy and environmental design (LEED) certification and other systems that analyze and rate energy-efficiency steps are important, but they’re based on a single point in time, a snapshot. Ensuring energy efficiency over time requires ongoing measurement and necessary adjustments – known as continuous commissioning. This process ensures a system aligns with needs and maximizes savings. Buildings need to be recommissioned every year or risk an annual 15% increase in energy use as building usage shifts, so energy efficiency solutions should provide ongoing commissioning capabilities. This avoids the set-it-and-forget-it mentality, which is subject to savings erosion over time.

Facility managers want to reap the financial and sustainability benefits of energy-efficiency improvements. With a range of innovative systems and a variety of financing strategies available, funding shouldn’t be a barrier to moving forward. Any energy-efficiency investment — from lighting to chiller upgrade to solar PV panels — that makes business sense should be within reach. It’s simply a matter of finding the most practical approach.

Tom Pincince is president and CEO at Digital Lumens in Boston, Mass. Contact him at (617) 723-1200.