In brief:

- The maintenance function is a significant determinant to the efficiency and reliability of an electrical distribution system.

- Because of its universal applicability, electricians need to comply with all of the requirements in NFPA 70E, not just those one feels are relevant.

- The smart grid will require plants to be more proactive in monitoring and controlling electrical consumption.

Plant personnel have little control over the electrical supply upstream of the service entrance, but complete control over the distribution system within the plant. Yet many plants find themselves in the dark about electrical safety and system maintenance.

Solving an electrical distribution problem shouldn’t be a case of stumbling around blindly seeking diagnostic data. Instead, shine some light on the hardware components themselves. You might find obvious defects in cable routing or in panel layout. While you’re at it, it might be worthwhile to update your current single-line diagram to replace an out-of-date version.

Safety issues also need to be illuminated, as electrical systems carry not only power, but potential hazards, as well.

Figure 1. A panel cluttered as a result of repeated equipment and process upgrades can complicate maintenance and introduce potential hazards. (B. Miller Engineering)

“While arc flash gets a lot of attention, there are still electric shock and fire hazards in many facilities,” says Ben Miller, president of B. Miller Engineering (www.bmillerengineering.com) in Deerfield, Illinois. “These are the result of older systems that have been modified over the years and have exposed live conductors, excessive box and conduit fill, or inadequate equipment short-circuit ratings resulting from previous power system upgrades (Figure 1). Proper employee training often is overlooked as an important step to ensure that systems operate properly and safely. Downtime caused by operator error or accidents can be extremely costly.”

“Personal protective equipment, safety category ratings and arc flash calculation are,” says Frank Healy, Power Quality Products Manager at Fluke Corp. (www.fluke.com), “extremely important to plant maintenance personnel, as well as to engineers. In general, avoid working power live unless it’s necessary to troubleshoot performance. If live electrical work is required, carry appropriate liability insurance. Only qualified personnel are permitted to conduct live electrical work, and then only after conducting an arc flash survey and while wearing personal protective equipment and using measurement tools that are appropriately rated for the electrical environment.”

Figure 2. The presence of cobwebs in an electrical panel might be indicative of negligent maintenance practices. (EMP Engineering Services)

Figure 3. Mold growing in a panel might lead to carbon tracking and the problems that brings. (EMP Engineering Services)

Joseph Weigel, product manager at Schneider Electric (www.us.schneider-electric.com), says he’s spoken with thousands of customers and knows a bit about their current practices relative to their electrical distributions systems. “There’s one common universal problem many of these facilities face in their electrical systems,” he explains. “That is the lack of funding for, or lack of attention to, routine electrical system maintenance. Lack of maintenance ultimately will lead to failures that can interrupt production or operational processes, and it poses a serious safety hazard, as well.”

Douglas K. Smithman, P.E., president of EMP Engineering Services (www.empes.com), offers one easy-to-do answer: “Infrared inspections and periodic connector tightness checks are common, but cleanliness often is overlooked,” he says. “Cobwebs and using cabinets to store spare part and documents provide a backbone for dust accumulation and eventual problems with carbon tracking and failures.” (Figure 2 and Figure 3)

Thermal imaging has become commonplace in many daily plant operations, says Rick Maday, product manager at Fluke (www.fluke.com/irwindows). “It’s no longer left to a simple yearly inspection,” he explains. “As the frequency of IR inspections increases, so too does the exposure to and risk of arc flash. Enclosures must be opened to scan with IR and doing so greatly increases the likelihood of an arc flash explosion. IR windows can mitigate this risk. They let infrared scans be performed without opening enclosures, virtually eliminating the risk of an arc flash.”

Weigel also says, if he could choose one thing to help improve electrical system safety and reliability in most facilities, it would be to exercise more diligence about electrical maintenance and testing of electrical system components, and standards from the National Fire Protection Assn. (NFPA, www.nfpa.org) are a good place to start. “The standard NFPA 70B (Recommended Practice for Electrical Equipment Maintenance — 2006) is a useful guide to electrical equipment maintenance,” suggests Weigel. “Other sources, such as the original equipment manufacturer’s O&M documentation, also are useful to establish proper maintenance practices and intervals.”

{pb}Health checkup

Once the plant maintenance strategy is in place, several diagnostic tools can assess the health of your plant’s power distribution system.

“The infrared scans are a good start and easy to use for hot spots,” says EMP’s Smithman. “However, they’re not reliable for more complex problems unless the operator is well-trained. Coils with shorts, interlaminar shorting in armature iron, worn contacts inside a molded case breaker and arcing inside of metal-clad switchgear are but few of the problems that can be missed. Ultrasonic scans and load monitoring are good diagnostic measures. So is common sense. Look for malfunctioning heaters in outdoor ductways. Look for burnt fuses on items that aren’t under load or lightly loaded at the time of the inspection (Figure 4). Listen for noisy contacts and relays. Be aware of the smell of burnt insulation. In short, use your eyes, ears, nose and sense. They’re great diagnostic tools.”

Figure 4. Contact points in the electrical system should be clean, with no evidence of arcing, burning or other discoloration. (EMP Engineering Services)

Fluke’s Healy adds that “The best way to ensure adequate and reliable power supply is to perform a power survey and then regularly assess power quality at both the mains and at major loads – particularly if loads are changed or increased. While there’s always a chance that power supply from the utility might carry some kind of distortion, most power supply and quality problems are caused by equipment or usage cycles. That’s why it’s rarely sufficient to assess power only at the mains. A power quality survey assesses power consumption, usage cycles and signal distortion throughout the facility. Electrical environments change, and a system that worked fine a year ago might develop power quality issues later.”

“Our recommendation,” says Edwin Hoh, Market Development Manager at Agilent Technologies (www.agilent.com), “is to do preventive testing of all measurable test points on a routine basis, using compact and convenient tools like a handheld DMM rated properly for the plant environment (Cat III 1000 V, etc.). Ease of use, including remote measurement using Bluetooth technology, will help facilitate such practice. For plant maintenance, the cost in time and effort, not just the equipment cost, is always paramount.”

Regularly scheduled performance testing and validation of overcurrent protective devices such as circuit breakers and fused devices identify weaknesses that can lead to failure and safety hazards if they remain uncorrected, explains Schneider’s Weigel.

Standard bearers

NFPA 70E: Standard for Electrical Safety in the Workplace contains numerous parts that are relevant to the industrial plant maintenance and engineering function. “NFPA 70E provides a complete guide to electrical safety in the workplace,” says Miller of B. Miller Engineering. “Industrial electricians need to understand all of its requirements, rather than attempting to pick and choose those they feel might be relevant.”

[pullquote]For maintenance and engineering functions, there are increasingly strong references in NFPA 70E that maintenance of electrical systems shouldn’t be ignored for safety reasons, says Schneider’s Weigel. “Another universal shortcoming that should be of concern both to maintenance and engineering is the lack of accurate electrical single-line drawings,” he warns. “This is a common deficiency in almost every plant or facility that I’ve visited. Having inaccurate system drawings presents a safety hazard, as well as a potential financial liability exposure in the facility.”

Arc flash studies are of extreme importance and relevance, says Fluke’s Maday. “NFPA 70E requires that electrical equipment be evaluated to determine potential arc flash dangers,” he says. “This includes the PPE needed as well as establishing an arc flash boundary around the equipment. With frequent infrared inspections becoming prevalent and effective, companies are reluctant to alter this inspection technique. Post-study, many companies turn to IR windows to allow them to perform IR inspections.”

Section 130.3 is the most important part of NFPA 70E for electrical maintenance and engineering, says Timothy L. Gauthier, senior training specialist at AVO Training Institute (www.avotraining.com). “It covers the arc flash hazard analysis,” he explains. “It needs to be updated after a major modification or renovation. Review it at least once every five years.”

Fostering economies

Electrical power might be a commodity, but it doesn’t make a lot of sense to consume more than you need. If nothing else, it’s wasteful and a matter of doing your part to reduce the quantity of greenhouse gases and mercury that a coal-fired power plant would otherwise be forced to release to satisfy your excess demand. Yes, there are measures the industrial plant can take to help minimize its electric utility bill.

{pb}The so-called smart grid will bring changes and have an effect at the industrial plant level. Fluke’s Healy says “If a plant is in an area where smart meters have been implemented, then the utility might substantially refine its kWh charging scheme. In other words, it might monitor and even control the amount of power supplied at a given time, and will charge different rates for different levels of power consumed at different times throughout the day. The utility’s objective is to distribute power consumption evenly throughout the day, instead of having to provide substantial power supply at peak consumption times and then having to reduce supply during off hours. At the transmission and distribution level, the smart grid will have far more sophisticated switching, to both better route power supply and to control and limit the factors leading to power outages. Lastly, the smart grid aims to increase the local utility’s ability to receive power from alternative sources, such as wind, solar or cogeneration, and then redistribute it.”

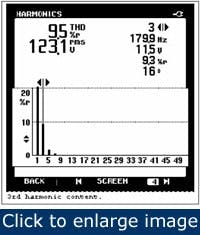

Figure 5. Power quality waveform anomalies that are present in the time-domain trace (top) are revealed in the frequency-domain trace (bottom). (B. Miller Engineering

“You can use the newer, more efficient lighting in combination with motion sensors in lightly used areas,” says EMP’s Smithman. “Not just more efficient motors, but more efficient use of motors also helps. Does a fan need to be on or off, or is a VFD a better way? Does a hydraulic system need to recirculate fluid, or can an accumulator provide most of the need?”

LEED certification is all about sustainability, says Larry Ray, director of Schneider Electric Engineering Services (www.powerlogic.com). “One major component is energy efficiency,” he explains. “LEED certification requires adherence to ASHRAE 90.1, a standard for energy-efficient buildings. To ensure ongoing energy efficiency, each type of LEED certification — existing buildings, commercial interiors and new construction — also requires close monitoring of the facility’s energy usage. This, in many cases, requires submetering of the facility and presents an excellent opportunity for a company to implement power quality monitoring at the same time.” (Figure 5)

Each type of LEED certification requires fundamental commissioning of the plant’s energy-consuming systems, continues Ray. “While it is common practice to ensure equipment is functioning properly, commissioning can be overlooked in the rush to complete the project,” he says. “LEED commissioning requires that the facility go one step further to ensure the proper functioning of each energy-consuming system. This can help avoid improperly installed lighting and HVAC systems and the resulting negative impact to the facility’s electrical distribution system.”

Stay safe

Shock and electrocution as a result of contact with energized components is still a common occurrence, says Schneider’s Weigel. “In electrical systems, the electrical hazards are shock, electrocution, arc flash and arc blast, all of which are addressed in the NFPA 70E,” he explains. “Machine safety and safeguarding also are vitally important to protect workers from injury. Much of the existing electrical equipment, including machine safeguarding components in existing systems, often is non-existent, very old and poorly maintained.”

Weigel estimates, in the United States, fewer than 10% of facilities are currently fully in compliance with NFPA 70E. “But more than 90% at the operational level are aware of the NFPA 70E standard’s requirements and enforcement,” he explains. “The disconnect comes from a lack of understanding and focus by senior executives within the company to foster, maintain and fund an electrical workplace safety culture as a legal requirement and fundamental best practice for their companies.”

Besides arc flash, other electrical system safety hazards exist in the plant environment. “I have more stories of untrained personnel doing things in electrical systems that, in the best case, only put their safety in jeopardy,” says EMP’s Smithman. “In the worst case, they put other people’s safety on the line, usually while the other party is unaware of the possibility of the hazard. I once had a 2,300-V connection in a junction box blow to ground about 10 ft from me while I was talking to somebody. The root cause was a connection made up with nothing but 600-V electrical tape. The good news was that the box contained the shrapnel.”

Too many maintenance organizations act as though an electrical system doesn’t require maintenance because nothing electrical moves, so they don’t worry about it, claims Smithman. “Thermal growth, magnetic forces and vermin are but a few of the things that cause changes in an electrical system over time,” he syas. “Without maintenance, the net effect of items such as these will be failures.”