Safety training and PPE are not first-lines of defense

Nothing captures people’s attention more than a good show. Add fire or explosions and people will give you all their attention. Therefore, it is not surprising why the industry gives its complete focus to electrical safety for arc flash. It is a showstopper – with its 19,400°C (or more) of heat capable of destroying a business and the lives of anyone in its path in just a tenth of a second. Arc-flash safety is important; however, the electrical industry’s deadliest act – electrical shock – is often forgotten.

More than 90% of electrical fatalities among U.S. workers are from electrical shock. This number does not account for the high proportion of fatalities that are often misclassified under a different cause of death. And yet shock is downplayed within industrial settings. Most electrical safety training programs do not cover shock. Even with training, workers usually do not exercise precaution against it, at least not enough to cut the power before proceeding to work.

Oftentimes, companies’ safety methods primarily focus on providing workers with personal protective equipment (PPE) and safety training, which they assume makes them safe from any incidents. However, PPE is considered the last line of defense on the hierarchy of controls, with safety training (an “administrative control”) falling next in line. A last line of defense is a last resort, and thus for companies to devote their resources to using last-resort protection methods, the disproportionate rate of worker fatalities that occur from electrical shock each year comes as no surprise.

What makes electrical shock so dangerous

An electric shock is a sudden violent response to electrical current flow through a person’s body. Even minor shock injuries can result in life-altering and debilitating symptoms. Electrical shocks can cause long-term injuries that can cause neurological, psychological, and physical symptoms. People suffering these symptoms often do not realize that these are due to a past electrical shock injury.1,2

It is the current – not voltage – that kills. Many factors contribute to the amount of current that enters the body, which is why a lower voltage does not indicate safety.

More than 99% of the body’s resistance to the flow of electrical current is at the skin.3 Skin’s resistance becomes far less protective against electrical currents when:

- there is a breakdown of skin at 500V or higher;

- the skin is damaged through cuts, abrasions, or burns;

- it is immersed in water; or

- there is a rapid application of voltage to an area of the skin.3

The human body, which is composed mainly of water, has a very low internal body resistance, between approximately 300 Ω and 500 Ω. The skin has a much higher resistance. The dryer the skin is, the higher its resistance will be. A calloused hand will typically have a resistance of around 100,000 Ω due to the thick outer layer of dry dead cells at the skin’s surface.3

There are many factors that cause a lower body resistance. A person with sweaty hands, for example, will have a lower body resistance and can be electrocuted at a lower voltage than what would otherwise be nonlethal.

Abrasions on the hand allow the current to bypass the skin resistance. The skin acts similar to a capacitor – it allows more current to flow when a voltage rapidly changes. If a person’s hand is holding a metal tool that suddenly touches a voltage source, the rapidly changing voltage will be applied to the person’s palms and fingers. If this happens, the current amplitude within the body will be significantly higher than would otherwise occur.3

The let-go threshold is when a person is experiencing an electrical shock and loses their ability to let go of the object. This often is the difference between life and death. Alternating current (AC) repetitively stimulates nerves and muscles that cause sustained contraction onto the muscles. These contractions do not stop so long as there is contact with the object. When a person’s muscles contract, their grip tightens. Once the current passes through the heart, fibrillation, resulting in brain damage and eventual cardiac arrest, is likely.

What electrical shock incidents data is missing

No one is immune to dying from an electrical incident, regardless of their qualifications. More than 64% of all electrical fatalities occur in non-electrical occupations.9 Thus, companies still have a high risk of a fatal electrical shock incident occurring regardless if their personnel consists of qualified workers. Accidents happen.

Electrical injuries are particularly underrepresented in occupational injury and fatality data because many are classified as a different type of incident. For example, if a worker is shocked while on a ladder to change a light fixture and falls from the ladder, the cause of death is a fall, not electrical shock.

It is also difficult to gauge the full extent of fatalities due to electrical shock because of a lack of consistent, transparent, and complete fatality data between the Occupational Safety and Health Administration (OSHA) and the Bureau of Labor Statistics (BLS) data sets.

Industry reports4 say that electrical fatalities have steadily declined since NFPA 70E became required. This belief is outdated. A two-year sliding average of these rates finds that this trend nearly flatlined after the fatality rate sharply dropped in 2007 after OSHA published 29 CFR Part 1910, subpart S, which was the first revision to OSHA’s general industry electrical standard in 25 years. This steady stream of electrical fatalities, including those due to direct exposure, isn’t even the full picture.

Most companies have detailed and comprehensive safety policies, regular training in NFPA 70E, and regular safety meetings and logs, which makes the occurrence of an electrical accident seem impossible, “but preventing electrical accidents requires more than policies and training - it requires utilizing safe work practices 24/7 without exception. A checklist indicating a worker has PPE is not a guarantee that the PPE will be worn and worn properly. … A worker is often more focused on fixing the problem rather than navigating the gray area of selecting the most appropriate PPE for an undefined task.”10

Every shock fatality is preventable. Electrical injuries are among the costliest type of worker injury due to their high medical and associated rehabilitative costs.9 Human life is priceless, and the cost of an incident exceeds far beyond even the steepest of OSHA fines.

The first step is to understand why PPE and training methods will not always work, and hazard elimination using components like GFCI protection is the solution. Littelfusesurveyed 575 people who work directly with electricity from Jan. 23 to Feb. 21, 2020:

- The respondents were spread across industries such as manufacturing, electrical maintenance and repair, and utilities.

- About 70% of respondents primarily work with more than 220V, and 30% mostly work with 220V or less.

- Company size was evenly represented among the respondents (29% work at companies with more than 1,000 employees; 21% work at companies with 1 to 19 employees).

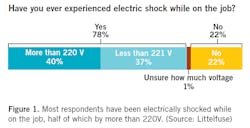

Finding #1: A shocking paradox – Confidence in ability to recognize an electrical hazard and a history of being shocked. Nearly 40% of the respondents said they have been shocked by more than 220V while on the job, which was about half (51%) of the 78% who reported having experienced electrical shock at any voltage (see Figure 1).

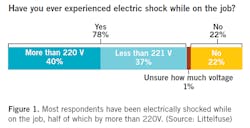

Most (85%) of the respondents who reported having experienced more than a 220V shock also rated themselves as either “very confident” or “extremely confident” when they were asked to rate their ability to recognize an electrical hazard. This was significantly more than those who have never been shocked when on the job and slightly higher than those who reported having experienced shock from less than 220V (82%) (see Figure 2). Overconfidence was also frequently cited among respondents as the main reason why people at their facility work on live equipment.

Finding #2: In the heat of the moment, even the best safety training tends to be forgotten. More than two-thirds of the respondents said that workers in their facilities perform work on energized equipment. The most common reason cited for doing so was the same for both groups: to maintain production and troubleshoot.

When respondents were asked an open-ended question to cite the main reason people at their facilities work on energized equipment, troubleshooting was the most common justification, followed by production purposes (such as to avoid the economic loss from stopping the equipment), overconfidence, and rationales like laziness and convenience.

Workers often intend to just look, but in the context of determining the cause of the problem, this often cascades into a situation where the worker is suddenly troubleshooting energized equipment without proper PPE or safety protocol. Simple, quick fixes that change the nature of the work are easy to slip into.

So why, despite having received electrical safety training from their companies, have most of the survey respondents experienced electrical shock while on the job? “Written safety policies prohibit work on live circuits, but workers sometimes fail to recognize the injury potential of troubleshooting/working on live lower-ampacity circuits or using electrical test equipment.”10

Finding #3: Let-downs in safety training. When analyzing the results, it became clear that safety training frequently does not work. For example, every respondent who cited PPE (or a form of it, such as gloves) as the main reason for why workers at their facility work on energized equipment also said their workplace provides them with safety training. If a worker believes they do not need to de-energize equipment so long as they wear PPE, then their safety training failed.

Alarmingly, among the respondents who cited PPE (specifically gloves and boots) as the main reason for not de-energizing equipment before working on it also said:

- their facilities do not send their electrical gloves to a laboratory for testing (which they are required to);

- they consider 550V or less to be a safe equipment voltage to ground to work on or near (their choices were a: less than 50V; b: less than 120V; c: less than 240V; and d: less than 550V).

Research indicates that “many workers who experience electrical injury had inadequate safety training to recognize safety hazards and follow proper procedures”.10 Such deficiencies include:

- the training misses important NFPA 70E topics;

- the training does not cover the current edition of NFPA 70E;

- the trainer is not qualified;

- the training does not address the information that is pertinent for electrical workers to know.6

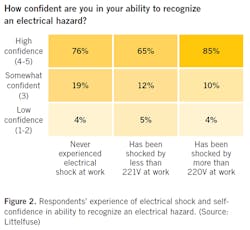

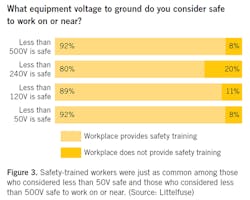

The survey found no connection between an accurate knowledge of how much voltage is safe to work on or near (50V) and those whose company provides them with safety training (see Figure 3). The rate of safety-trained workers among those who considered more than 50V to be hazardous to work on or near was just the same as the rate of safety-trained workers who believed up to 500V to be a safe working voltage.

More than 50V of equipment voltage to ground is not safe to work on or near. However, when the survey asked the respondents how much equipment voltage they consider to be safe to work on or near, a quarter of the respondents incorrectly believed more than 50V is safe:

- 9% said up to 120V is safe;

- 5% said up to 240V as safe; and

- 9% said 500V is safe to work on or near.

Almost 90% of those who considered 500V to be safe said their workplace provides them with safety training. Among those who believed up to 500V is safe, 62% said they have experienced electrical shock by more than 220V while working.

If a worker cannot identify a safe working voltage from a hazardous condition, then their safety training failed. Any pertinent safety practices the worker was able to retain are ineffective if they can’t identify a hazard to begin with.

A corporate case study found that 40% of electrical injury incidents involved 250V or less and were indicative of a misconception that electrical safety is a nonissue in low voltages.7

If safety training does not help to decrease the misconception that more than 50V is dangerous to work around, and if 40% of incidents involving 250V or less are due to this misconception, then safety by design is essential, even where not required under NEC.

Simply put: safety training does not guarantee incidents won’t happen. Electrical injuries and fatalities are one of the most preventable types of occupational injury and fatality, and yet they continue to happen.

Unlike other occupational hazards that center around the worker’s behavior, electrical hazards can be eliminated using “hard-science” methods like ground-fault circuit interrupters (GFCIs), which do not rely on human-based behavior for them to work.

Finding #4: Haphazard PPE Practices. While important, electrical gloves are the last line of defense. Electrical gloves must maintain their dielectric properties, physical strength, flexibility, and durability for them to remain effective. Whether the worker wears them is a different story.

Workers often complain electrical gloves make it difficult to get the job done because they are cumbersome or bulky.10,11 For female employees, this issue is even more present: electrical gloves are not currently made to fit women’s hand proportions.11 This is particularly dangerous when you consider that workers often don’t wear their gloves because of their fit; and the misinformation within the industry that the let-go threshold for the human body is 9 mA, which does not take women into account.

Almost a quarter (23%) of respondents said their facilities do not test their electrical gloves (which is required to be regularly done under (CFR 1910.137). Another quarter of the respondents said they were unsure if their facilities test them.

Safety is already at odds against shock hazards when PPE and training are the only hazard mitigations used by a company. To issue human-error prone workers PPE and then assume it to be in working condition without it undergoing required testing is reckless. PPE is important, but it is not good enough.

Rubber mats do not eliminate the potential for injury and fatality incidents, just like all other forms of PPE. Workers do not always use the mats due to the extra work they create when breakers or contactors are racked in or out. Rubber mats are also rendered ineffective when wet.10

These pitfalls can be eliminated through safety by design. For example, in wet applications, a three-phase GFCI (which can be used with a cart for portability), is the optimal solution to protect against shock.

Why safety by design matters

NEC does not require GFCI protection for all areas where shock hazards that can injure or kill a person exists. PPE, however, is required whenever a worker’s safety is at risk. This is problematic: PPE is the least effective method because it relies on human variables for it to work. GFCIs eliminate the hazard all together. GFCI protection is an out-of-sight-out-of-mind practice that requires zero energy from the workers for it to guarantee their safety.

This is why Class C, D, and E special-purpose GFCIs (SPGFCIs) are so important: they are responsible for monitoring the ground-return path continuity and then to interrupt power if any integrity is lost. This in turn eliminates the possibility of electrical shock.

Consistent execution

Only in the aftermath of tragedies is it easy to understand the importance of proper safety prevention. Human-based safety methods require consistent precision in their execution: without error, by every person, and every time. This is not possible because people make mistakes; it is only human. If safety training worked, workers would have a more accurate understanding of what makes an electrically hazardous situation, and shock injuries and fatalities would, at the very least, have leveled off over the past several years.

Mark Pollock is a global product manager at Littelfuse. He is active in IEEE and has a B.Sc. in electrical engineering and computer science from the University of Saskatchewan. He also is a past Chairman at IEEE in the North Saskatchewan chapter.

Rachel Metea is the technical writer at Littelfuse. She holds a BA in communications and an MA in journalism from DePaul University. Rachel is a member of IEEE.

References

[1] M. S. Morse, “A report on the current state and understanding of human response to electrical contacts,” presented at the IEEE Industry Applications Society Electrical Safety Workshop, Dallas, TX, USA, Mar. 11–15, 2013, Paper ESW2013-05.

[2] M. R. Zemaitis, L. A. Foris, R. A. Lopez, et al, ”Electrical Injuries,” StatPearls Treasure Island (FL): StatPearls Publishing; 2020 Jan. Available from: https://www.ncbi.nlm.nih.gov/books/NBK448087

[3] R. M. Fish and L. A. Geddes, “Conduction of Electrical Current to and Through the Human Body: A Review,” Eplasty, vol. 9, no. 44, Oct. 2009. Accessed: Mar. 04, 2020, [Online]. Available: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2763825

[4] Workplace Injury & Fatality Statistics, Electrical Safety Foundation International, 2019. [Online] Available: https://www.esfi.org/workplace-injury-and-fatality-statistics

[5] R. Bingham. “Flatlining: The Decline in Electrical Fatalities Has Nearly Leveled.” Electrical Contractor. https://www.ecmag.com/section/safety/flatlining-decline-electrical

-fatalities-has-nearly-leveled accessed (Mar. 13, 2020).

[6] T. Gammon, D. Vigstol and R. Campbell, “Workers at Risk of Fatal and Nonfatal Electrical Injuries,” IEEE Transactions on Industry Applications, vol. 55. no. 6, Nov./Dec. 2019.

[7] R. B. Campbell and D. A. Dini, “Occupational Injuries From Electrical Shock and Arc Flash Events,” Fire Protection Research Found. Quincy, MA, USA, Mar. 2015.

[8] Department of Labor, Federal Registrar, 29 CFR Part 1910, Subpart S. Available from: https://www.osha.gov/sites/default/files/laws-regs/federalregister/2007-02-14.pdf

[9] B. Brenner, J.C. Cawley and D. Majano, “Electrically Hazardous Jobs in the United States,” IEEE Transactions on Industry Applications, to be published. DOI 10.1109/TIA.2020.2980221.

[10] T. Gammon and S. Jamil, “The Disconnect Between Electrical Safety and Accident Prevention,” IEEE Industry Applications Magazine,” to be published.

[11] Industrial Accident Prevention Association and Ontario Women’s Directorate, “Personal Protective Equipment for Women – Addressing the Need,” The Center for Construction Research and Training, Silver Spring, MD, USA, Accessed on: Mar. 16, 2020. [Online]. Available: http://elcosh.org/record/document/1198/d001110.pdf