Potential energy savings for two-step controller is next to nothing

Part 1 of this two-part article covered an overview of the five-step (variable displacement) controller central compressed air management system and examples of five-step and two-step controls. Potential energy savings with a two-step controller with examples and charts also were provided.

Real action at a real system

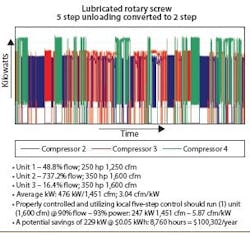

Figure 1 is a schematic of three lubricant-cooled rotary-screw compressors with a five-step variable-displacement controller. The units were converted to two-step control and used a simplistic central compressed air management system with a fixed sequence. The demand is only 1,450 cfm, yet we have the total 4,200 cfm online operating inefficiently all the time with the units using too much power and short cycling (Figure 2). This is the actual system with two 350-hp and one 250-hp lubricant-cooled rotary-screw compressor with five-step variable displacement poppet valve capacity controls. The relevant data:

Figure 1. Converting these lubricant-cooled rotary-screw compressors from two-step control to five-step variable displacement controller saved more than $100,000 per year.

Figure 2. All units exhibit extreme "short cycling" and the control manufacturer is still trying to correct the problem.

- Unit 1: 250 hp, 1,250 cfm operating at 48.8% flow

- Unit 2: 350 hp, 1,600 cfm operating at 37.2% flow

- Unit 3: 350 hp, 1,600 cfm operating at 16.4% flow

- Average power consumption: 476 kW at 1,451 cfm (3.04 cfm/kW)

If operating properly and using local five-step control, the system should have only one 1,600-cfm unit online operating at 90% flow and 93% power. This translates to 247 kW at 1,451 cfm, or 5.87 cfm/kW. This more efficient configuration would yield a potential annual savings of 229 kW x 8,760 hrs/yr x $0.05/kWh = $100,302/yr.

The bottom line is that a fully competent compressed air system audit should precede any design or control selection because it accurately identifies the pressure and demand profile. In any case, remember that you can eliminate surge demands that might upset a control scheme by using local storage to convert a surge into a low average demand.

Another real system

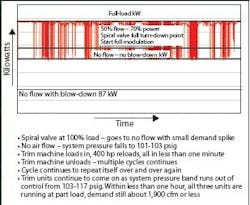

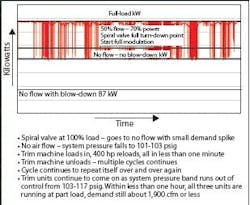

The three 24-hr trending charts (Figure 3a, 3b and 3c) indicate that one 400-hp, one 150-hp and one 100-hp compressor are on line and operating at part load. Also, the flow profile (1,720 scfm to 1,900 scfm with peaks to 2,000 scfm) is erratic and not representative of the apparent air demand. The charts reveal an operating pressure band between 103 psig and 117 psig with evidence of extreme short cycling. The nameplate demand of the connected users is near the full load of the 400-hp unit. When the system pressure falls, the control system first brings up the designated 150-hp trim unit. It comes on at full load and then overdrives the system pressure, fully unloading the 400-hp unit and immediately removing 1,728 scfm from the supply.

System stability collapses quickly, bringing a second 100-hp trim unit online to help the 400-hp base unit, overdriving the system again before the controls can catch up. The system continues to run out of control with too many units running at part load and short cycling. None reach a sustained idle and shut off.

We see far too much of this type of problem, which some careful planning can so easily avoid. The fix for this system was simply reconnecting the local five-step variable-displacement control on the 400-hp unit and allowing it to run base load outside the control of the central air management system. If you look, you’ll find modern well-thought-out central air management systems that can support two-step controls on both small and large units. Usually, these have the ability to control five-step units, modulation units and, perhaps, even centrifugal compressors without requiring that you convert all units to two-step control.

If you’re investigating a central air management system, be sure that its specific capabilities fit your situation. If it allows you to keep the five-step control operating as a five-step, your control will be a lot more responsive and reliable. When in doubt, observe candidate systems in operation. Even those with limited flexibility are described as having the same features and, of course, they all have so-called smart electronics. The real secret is in the knowledge and experience of the software developers and their understanding of a capacity control system and its effect on various types of compressors under various conditions.

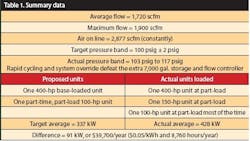

The data from the 24-hour trend curves for the central air management system study show:

- Three units online simultaneously, each operating at part load

- 2,948 cfm online, 1,720 cfm average demand (base unit capacity is 1,768 cfm)

- Demand peaks between 1,900 cfm and 2,000 cfm

- Pressure swings from 103 psig to 117 psig

The relevant data is summarized in Table 1. The two-step controller has a slower response time than either variable-displacement or modulation control. Therefore, it can’t respond as effectively to system dynamics. But, of course, you can do better than that in your own plant.

Hank van Ormer is owner of AirPower USA, Pickerington, Ohio. Contact him at [email protected] and (740) 862-4112.