It might not be opera, but you know what you like. Air compressors run most economically when well maintained, in their highest-efficiency operating range, and at their lowest design pressure. In an ideal system, all but one compressor will be fully loaded or turned off, and the combination of compressors will be the one best suited for the current load.

But few facilities have the luxury of an ideal compressed air system. They tend to grow as production is added and changes, and depend on funding, capital and real estate. “They’re evolved rather than planned, with big and small compressors, in annexes or wherever,” says Randy Finck, global category manager, Ingersoll Rand Industrial Technologies (www.ingersollrand.com). “So you play the hand you’re dealt.”

Maximize potential savings

Compressed air systems typically waste 20% to 60% of the input energy. “Systems are designed for the periods of highest demand on the largest shift, plus a fudge factor,” Finck says. “Other periods and shifts typically use less air, so the average load is 60% to 70% of capacity. Part of the 20% to 60% inefficiency is because too many compressors are running, and they’re not the right compressors for the load.”

The problem is compounded when compressors are decentralized. “In general, we want to have them in a central location,” says Wayne Perry, technical director, Kaeser Compressors (www.us.kaeser.com). Instead, “People have compressors scattered all over, each running itself with no central control. Decentralized systems are hard to keep efficient.” If demand goes down in part of the plant, the local compressor might spend more time unloaded, but it can’t be shut off. So it runs less efficiently.

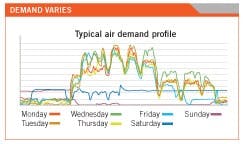

Figure 1. Most plants run too many compressors, too much of the time because once they turn on a compressor to support peak production, they never turn it off. (Atlas Copco)

“During this time of economic slowdown and consolidation, users might be causing inefficiencies by doing things like running a 200-hp compressor on a 50-hp load,” says Steve Briscoe, corporate sales manager and U.S. DOE AIRMaster+ Specialist, Brabazon Pump, Compressor & Vacuum (www.brabazon.com). “They might get a big compressor from a closing facility, run it on a small load and waste a lot of energy. That ‘free’ compressor might cost more than paying for the right piece of equipment.”

Today’s intelligent, microprocessor-based, Web-enabled control systems can be set up to get the best out of virtually any combination of compressors, but like any other effort to improve a system, it’s best to start with an audit. “Everyone believes they understand how their system works,” says Briscoe. “In fact, every system is different, and there’s no one fix.”

[pullquote]

An audit includes evaluation of compressed air demand (pressures, leaks, inappropriate uses) and distribution (storage, manifolds, piping) before recommending changes to the supply-side compressors or controls. (For more about audits, see the “More resources …” sidebar.) “By itself, going from electromechanical to electronic controls might give 2% to 4% energy savings,” says Mike Iacino, vice-president service marketing, Atlas Copco (www.atlascopco.com). “Doing it with an audit might give as much as another 15%.”Controls and automation aren’t an end in themselves. “Alone, they do nothing,” says David Booth, U.S. Department of Energy AIRMaster+ Specialist, Sullair Corp. (www.sullair.com). “Automating a poorly designed or badly installed system just adds complexity. You might get improvement, but it’s not optimal because you didn’t get to the core problem. Fix the system first.”

Shut ’em off

“The most efficient machine is the one that’s not running when you don’t need it,” says Forrest Landes, engineering supervisor, Controls Dept., Compression Systems, Cameron (www.c-a-m.com).

One of the newest controller developments is adaptive algorithms. You program in the sizes and capabilities of the compressors, and it matches the combination of compressors to the demand. As demand changes by shift or time of day, the controller adjusts and uses the most efficient set of compressors.

Most plants run too many compressors, too much of the time. Part of the reason is variation in demand (see Figure 1). “When production sees low pressure, they call maintenance to turn on a compressor. They never call to turn it off,” Finck says. “Which compressor is turned on? There’s no management. You want the big compressors on the main shift, and the small compressors on off shifts. Controls automate that.”

Multi-compressor control systems automate compressor shut-down according to demand, but might keep extra capacity or pressure available in case it’s suddenly needed. Operations scheduling can be used to set pressures or toggle machines off and on based on a clock or calendar, says Emmett Sills, service trainer, Atlas Copco (www.atlascopco.com). “Timers can shut down unneeded equipment at night or on weekends, and turn them back on so it’s ready when everyone comes back in.”

Off is good. “We prefer to run a compressor either on or off,” Perry says. “Variable-speed compressors have their place, but they’re not as efficient as a fully loaded, fixed-speed compressor because of the losses in the variable-speed drive.”

[related]

Keep pressures down

If running too many compressors is the main cause of energy waste on the supply side, then running pressure too high is second. “The other main source of waste is excess system pressure,” Finck says. In typical compressed air system pressure ranges, “Every 2% increase in pressure loses about 1% of efficiency.”

“Compressors run at high pressures for the same reasons that too many are running: Production calls for more. We don’t want to be the reason why production slows or a tool breaks. But the more you raise the pressure, the more air the process will use.”

People think point-of-use regulators prevent this, but when you go out and look at them, many are turned all the way up. And more pressure means more leakage. “The average plant has a 20% leak rate,” Finck adds. “Raising the pressure from 100 psi to 125 psi will increase leakage 12%. That’s a lot.”

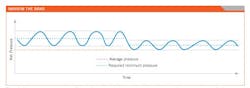

The traditional way of staging compressed air systems is with cascade controls: As system pressure drops, more compressors turn on. As it rises, they drop off. Each compressor uses its own controls and runs in is own pressure band. “The problem with staggering pressure switches is you need to have your final compressor 20 psi to 25 psi higher than the needed pressure,” Briscoe says (Figure 2). Most of the time, the system runs well below its capacity, so it runs well above the lowest pressure — it only runs production’s minimum pressure at 100% output.

Along with excess pressure drop, cascade systems are prone to drift in the individual controls. “When each compressor tries to operate itself, none get the same pressure signal,” Perry says. “When people try to cascade them, they get horribly out of balance.”

One step up from cascade is sequencing controllers. These use a single pressure band to control multiple compressors. For example, if the needed pressure is 100 psi, set the pressure at 102 psi. When the pressure drops to 101 psi, the sequencer turns on the next compressor.

Electronic systems go one step further by using algorithms for each size and type of compressor to choose the right combination for a given demand situation and to minimize total power requirements.

Hold your horsepower

A system might have a combination of fixed-speed, fixed-capacity, variable-speed or variable-capacity compressors. These could include rotary, reciprocating or centrifugal designs.

There are several types of capacity control for individual compressors, sequencing controls for multiple compressors and pressure and flow controls for compressed air systems. The correct selection of each determines system efficiency over the anticipated operating ranges. “The rules for achieving optimum efficiency are one: Only the number of compressors needed to maintain the required system pressure should be in operation at any given time, and two: All but one, a trim compressor, should be running at full capacity and pressure,” says Bill Scales, P.E., owner, Scales Air Compressor Corp. (www.scalesair.com). “The trim compressor should have an efficient capacity-control mode. If it’s a reciprocating compressor, this could be unloading in a series of capacity steps. For a rotary compressor, variable-speed control or variable displacement is most efficient.”

Controls programmed with algorithms for individual compressors can help you run the best combination of compressors at full or partial loads. For example, centrifugal compressors can be especially difficult to control at partial loads. “We’re a centrifugal compressor company, so we directly replace controls on centrifugals,” Landes says. “We can integrate different kinds of machines by designing the system to do that. It can handle modulation, surge control, turndown limitations and coordinating multiple machines.”

An air-end’s efficiency peaks at its design speed, typically 1,800 rpm for direct drive and higher speeds, perhaps 5,000 rpm, on gear-driven compressors. “An air-end designed for variable speed will have a broader efficiency peak but it won’t be quite as high,” says Steve Centers, manager, electrical engineering, Quincy Compressor (www.quincycompressor.com). “As you slow a screw compressor, there can be more blow-by at the rotor tips, further decreasing efficiency.”

Some compressors are offered in variable-capacity versions. “Along with variable speeds, we also offer compressors with a bypass system for capacity adjustment,” Centers says. “Lift valves can open ports on the compressor, effectively reducing the lengths of the screws. Four lift valves reduce the compressor capacity in 12.5% increments from 100% to 50%, without the losses associated with variable-speed drives.”

Those losses in variable-speed-drive (VSD) compressors are being addressed with more efficient controls and air-ends. “VSD is the de facto standard of efficiency for trim,” Booth says. “Now we have specific air-ends for VSD, and geometry control, or variable displacement. It interacts with the controls to give higher efficiency at turndowns.” The VSD controls now are part of the compressor controls, not a separate controller, to simplify the system. Built-in tools are used to configure the controls and VSD simultaneously.

“At 100%, a fixed-speed compressor is most efficient,” Centers says. “At 80%, the VFD is most efficient. At 50%, the lift valves are most efficient. We think the future calls for a mix of technologies to maximize efficiency. We’re developing a control system that can handle a combination of base, variable-capacity and variable-speed compressors and run the right one or right combination for a given load.”

The role of flow control

Perhaps the wildest frontier in compressor control is getting feedback from the demand side that allows supply side machines to anticipate load changes. “We’re looking at predictive controls, where we would know that equipment is firing up,” Booth says. “When we understand the demand side, we can integrate it.” But where compressor and control systems remain independent, a practical approach often is to separate demand from supply using a pressure flow controller.

“There are three parts to a system: the demand that’s used, the supply coming in, and the distribution/storage system,” Booth says. “Demand can often overwhelm supply, and supply is always over or under demand. The storage and distribution system mediates.”

A pressure flow controller is a valve or valves between the demand side and a storage vessel on the supply side. The valve is controlled by a pressure signal to keep the demand-side pressure low and constant. “The keys are fast response, little or no restriction (pressure drop), and constant output pressure — plus or minus 1 psi despite input pressure variation,” Booth says. “They can be pneumatic or electronic.”

Without a pressure flow controller, any rapid change in demand must propagate back through filters and dryers to reach the compressor controls. A flow controller can detect that change and signal a compressor to turn on. But unless the system is tuned and stays in tune, the pressure drops at filters and dryers can overload the compressors. It also can get complex with multiple compressors on separate filters and dryers.

In practice, pressure flow controllers generally are used to keep the demand side pressure low and constant, while the storage and supply side pressure are kept somewhat higher and allowed to vary. “You can minimize plant air pressure because there’s no drop during the lag before compressors turn on,” Booth says.

Pressure flow control also can be used to run the plant air at a pressure lower than the compressor design would allow. “For example, lubricated screw compressors will carry oil over if the pressure is too low,” Booth says. “So store the air at the lowest compressor pressure, say, 80 psi to 100 psi, and operate the plant at a lower pressure via a pressure flow controller. The higher-pressure storage will buffer plant air pressure drops during short increases in demand.”

More efficient maintenance

Electronic controls offer the opportunity to streamline compressor maintenance and improve reliability for reduced and busy staffs. “Our touch-screen-equipped controllers can be accessed with a Web browser and if you set up the security to allow it, you can to monitor the equipment, collect data, change variables, even start and stop the compressors over the Internet or a company intranet,” Centers says. “Browser technology provides a familiar look and feel, and reduces training requirements.”

Controls can warn of impending failures, notify you when they’re out of adjustment or outside setpoints, track actual hours and send an e-mail when preventive maintenance is due, and collect historical data for analysis or troubleshooting.

“The controller records variables such as cumulative kilowatts-hours and flow for efficiency calculations — a year’s worth of data,” Perry says. “It’s like an ongoing audit, where you can see the effects of shift changes, production changes, a new machine. It helps plans for expansion, or these days, contraction. One of our customers is an automotive supplier who’s keen on maintaining efficiency as production drops.” Historical information also lets you see if you’re running the right combination of compressors for base and peak demand under varying production loads.

“Through Web and LAN technology, we can control remotely and do reporting,” Booth says. “A service provider can take a look before coming out to do service. What’s the condition? If temperatures are running high, is the cooler plugged?”

Inputs for sensors can be used to monitor related equipment and variables such as filters, pumps, cooling towers, temperatures and flows. “Our service tech can log in and see every machine — dryers, drains, everything — so he can evaluate it and decide the urgency,” Perry says. “Is it an emergency or can it wait? He can both prevent a shutdown and avoid paying time-and-a-half.”

The cost of electronic controls is coming down and competing directly with conventional electromechanical systems. “Electronic controls now can cost less than a set of gauges, relays and pressure switches,” Booth says. “Should we offer the machines with a controller as an alternative to gauges at the same cost? Should we upcharge for the gauges? These are now the questions.”

The volume production of standard electronic hardware and software that drives down costs also brings previously unimagined capabilities. “We chose Windows CE for a familiar look and feel for graphics and Windows connectivity via Ethernet, FTP and USB,” Landes says. “These days you can roll it into one system that’s proven, deterministic and has vendor support.” There also are readily available modules, such as Modbus, for connectivity to integrate air, control and SCADA systems.

“Electronic controls offer reliability and control of multiple machines,” Iacino says. “You can use one standard controller, a standard transducer, a standard pressure switch, and reduce inventory.

“You can reduce maintenance by working with actual run times. You can monitor pressures, temperatures, vibration, flow, dew point, motor temperatures. You can spot problems like leaks or inappropriate use, 24 hours a day, and get a monthly report on machine usage and events. You can do all that over the Web from anywhere.”

“You can do it yourself or have us do it as part of a service agreement. You can see when a problem is developing, see it in detail and see it before it shuts down the machine.”

E-mail Paul Studebaker, CMRP, editor in chief, at [email protected].

Compressed Air ChallengeThe Compressed Air Challenge (CAC) is a national collaborative of public and private organizations dedicated to increasing the understanding and improving efficiency of compressed air systems within U.S. industry. The CAC offers Fundamentals of Compressed Air Systems and Advanced Management of Compressed Air Systems training, and in cooperation with the U.S. Department of Energy, the Compressed Air Systems Sourcebook for Industry as well as the Qualified AIRMaster+ Specialist training. CAC has built a reputation for being a reliable resource for cost-effective solutions and unbiased information, including the recent publication Best Practices for Compressed Air Systems, a comprehensive and detailed reference for plant personnel. For more information about CAC training and publications visit www.compressedairchallenge.org.