People on the plant floor know when not enough air compressors are operating. The demand-side system air pressure drops below what production equipment requires, which triggers phone calls and complaints. But, do people know when too many compressors are running and inflating your plant’s energy costs?

The Compressed Air Challenge, sponsored by the Department of Energy, has impressed upon us that compressed air is an expensive utility. Typically, only 15% of the input power to a plant’s air compressor system produces useful compressed air. The rest is wasted as heat and pressure drop. In addition, compressors running in a partially-loaded condition or, worse, totally unloaded for hours on end waste considerable energy and maintenance resources. Many compressors can consume as much as 70% of full-load power while delivering less than 30% of full-load capacity.

[pullquote]The controls on individual compressors try to match the compressed air supply with the demand. If supply exceeds demand, system pressure rises and one (or more) compressors need to reduce output or risk exceeding system pressure limits. Rotary-screw, centrifugal and reciprocating compressors, each with varying individual compressor controls, can be efficient if applied and operated properly. The paradox is that even compressors with energy-efficient part-load controls can be inefficient when operated together or in concert with other capacity control types or air compressor brands. This is where modern multiple-compressor controllers can alleviate the part-load energy waste and the effects of wide swings in pressure on your compressed air system and production.

Many multiple compressor controllers available today use different logic to solve the same problem. Some controllers merely start and stop compressors based on system pressure; some rely on time of day to determine which compressors to run, while others will work only with specific compressor types or those from only one manufacturer. The most advanced controllers address all of these situations. Let’s examine the evolution and application of some of the more popular types.

Cascading may require a wide band

Figure 1. Cascading-pressure control operates multiple compressors in a predetermined manner.

This form of multiple compressor control has been in use for a long time. Multiple compressors are controlled based solely on system pressure. As system pressure falls below a setpoint, additional air compressors are brought online in a predetermined sequence. In many cases, the compressor with the greatest horsepower is started first and subsequent compressors are selected in order of descending horsepower. If the system air pressure continues to fall to a lower pressure setpoint, the next pre-selected compressor comes online. This controller requires the plant to operate with a cascading pressure band (Figure 1).

For example, the lead compressor loads or turns on when system pressure falls to 100 psig. The next compressor in the sequence might turn on when system pressure falls to 95 psig and the one after that at 90 psig, and so on. As online capacity begins to exceed system demand, system pressure rises to allow the last compressor brought online to unload or turn off (in our example somewhere around 100 psig) The previous compressor brought online will require system pressure to rise to 105 psig before unloading or turning off. As the number of compressors increases, so does the pressure band and energy consumption.

In a nominal 100-psig system, a 2-psi increase in discharge pressure results in a 1% increase in input power to the compressor. In addition, higher system pressure increases the consumption attributed to all unregulated users and leaks. Often, systems with a cascade-type controller have insufficient storage capacity and require a wide pressure band. When the pressure differential between the compressors’ maximum allowable operating pressure and plant’s minimum required pressure is tight, too many compressors end up on line for the demand required, and the full benefit of individual compressor energy saving controls is lost.

Networking might not be the answer

Figure 2. Networked controls can maintain tighter control over pressure swings.

Connecting a microprocessor controller to individual air compressors improves response time to system demand changes and allows for network-type sequencing of multiple, similarly equipped air compressors (Figure 2). Networking multiple compressors allows them to operate within a tighter control band. Typically, the control scheme has only one compressor operating at part-load while the other compressors run close to or at 100% capacity at the target pressure. The controller is connected via a communication cable. A network-type multiple compressor control system usually requires that compressors be of the same type from one manufacturer, are equipped with the same microprocessor controller and will only control air compressors. Because communication among the network elements requires cable, it’s often impractical to connect compressors located in remote areas of the plant.

Smart sequencers optimize efficiency

With programmable logic controllers, modern sequencers have evolved with the ability to determine the most efficient combination of available compressors to meet the ever-changing plant demand efficiently and effectively.

Advanced smart controllers not only monitor system air pressure, but also monitor system demand (flow). These controllers can sequence various types of compressors and capacity control systems. Smart controllers also integrate dryers, pressure flow controllers and other ancillary equipment.

Smart controllers are preprogrammed with information unique to your compressed air system. They store data such as individual compressor size and type, response rate, system storage capacity, full and part load performance characteristics, capacity control type and system operating setpoints. A smart controller continuously monitors the percent load of the individual compressors along with the system’s compressed air pressure and volumetric flow demand. By combining the monitored data with the stored data, a smart controller considers the compressor type and capacity control to ensure only the minimum kilowattage is online to satisfy the demand.

Compressors are brought online when system pressure falls below the target pressure. However, compressors are taken off line based on system pressure and the system demand or flow. One or more flow meters collect the demand data and send it to the controller. The controller determines which compressors to turn off and which to leave on line.

Figure 3. A smart controller is capable of coordinating the performance of multiple, similar compressors having different operating characteristics.

Smart controllers also take full advantage of different capacity controls on individual compressors to maintain maximum system efficiency. As a plant’s production expands, so does demand for compressed air. Typically, the increase in compressed air requirements is met by adding air compressors of different sizes and manufacturers. For example, in a system that includes multiple rotary-screw air compressors of different sizes and vintages, all with pneumatic modulation inlet valve type control, the compressors meet the system demands effectively but not efficiently (Figure 3).

It’s not uncommon to have every available compressor operating at part load because total supply-side capacity is greater than system demand. As the compressors modulate to reduce output and match the demand, the pressure bands overlap. Because each compressor is modulating and reducing output, system pressure won’t rise and the plant is left with all air compressors running at part load, thus wasting considerable energy and increasing maintenance costs.

By integrating a smart controller into the system, the plant’s compressed air demand is monitored along with system pressure. When plant compressed air demand decreases to a level that can be met by the total capacity of one fewer air compressors, one unit will go into standby. The reduced number of online compressors will now operate closer to full load, thus saving considerable energy. As demand falls further, another appropriately-sized compressor is taken off line; or because the smart controller is programmed with the capacity of each compressor, a larger-capacity compressor might be taken off line and a smaller compressor brought back on. Throughout this process, the relatively narrow operating pressure band (2 psi to 3 psi) reduces energy and maintenance costs associated with higher operating pressures.

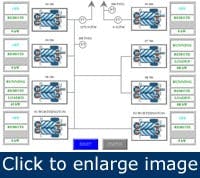

Figure 4. The ability to interconnect differing compressor styles is a good reason to use a smart controller.

In another example, consider a system with centrifugal compressors equipped with inlet guide vane controls and a rotary-screw compressor equipped with modulating inlet valve control (Figure 4). The smart controller directs the rotary screw to run fully loaded (at its most energy-efficient point) and then trims with one of the centrifugal compressors via its inlet guide vanes, maintaining excellent energy efficiency.

As system demand decreases, the controller continues to turn down the centrifugal unit, reducing output until maximum turndown is reached. If output capacity is still greater than demand, the controller begins to turn down the next centrifugal. By monitoring the demand flow, the controller knows whether to slightly modulate the rotary screw compressor or completely unload it. The load then can be supplied by one or both of the centrifugals or completely unload one of the centrifugals allowing the rotary screw compressor to operate fully loaded. Once again this is typically achieved within a relatively narrow pressure band of 2 psi to 3 psi.

Figure 5. Gain insight into compressor operations when the smart controller displays both measured and computed key performance indicators.

Smart controllers have many additional practical capabilities, including the ability to display the plant’s compressed air volumetric consumption rate; input power required to produce the compressed air; system efficiency data; peak, average and minimum demands throughout the day; and equipment status and alarms (Figure 5). A single smart controller can control compressors in different or remote rooms or even integrate multiple systems. Multiple plants can be controlled by a single smart controller through radio communication.

In addition to compressed air equipment, many modern smart controllers can control, as well as monitor and trend, other equipment (chillers, pumps, boilers, etc.) and utilities in a plant.

Generally, compressed air systems have become more modern and plant requirements more complex. Advanced smart controllers operate a system reliably, provide operators with the information needed to manage it properly, and above all, turn off air compressors that aren’t required.

Niff Ambrosino and Paul Shaw are general managers at Scales Industrial Technologies. Contact Ambrosino at (973) 890-1010 and Shaw at (203) 630-5555. Both are qualified instructors of Advanced Management of Compressed Air Systems for the Compressed Air Challenge workshops.