Are VSD-controlled compressors best for regulating air pressure?

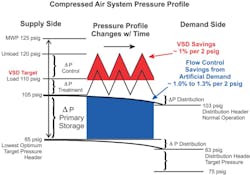

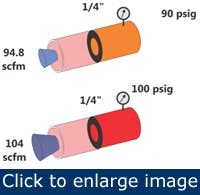

Figure 1. Airflow through an orifice as a function of pressure.

The idea of regulating the compressed air pressure of the whole plant from one location is a fairly new innovation. Operating a compressed air system at the lowest optimum pressure to meet the needs of production reduces energy cost. But there’s a controversy: Should compressed air pressure/flow control be used, or should modern compressor controls, especially VSD-controlled compressors, be used as an alternative to providing precise pressure regulation? Or is the best configuration using both?

What is artificial demand?

Artificial demand is defined as the excess volume of air that is required by unregulated end uses as a result of supplying higher pressure than necessary for applications. Compressed air flows from the compressed air system to atmosphere through an opening or hole in the system. That opening could be a leak, an air tool, a pneumatic cylinder, control valve or other production application. If there’s a hole or orifice in the air system, increasing compressed air pressure increases the airflow (Figure 1).

Flow rates for various orifice sizes and pressures are shown in Table 1. A 10-psig reduction in air pressure causes approximately 10% less compressed airflow.

| Orifice (in.) | Pressure (psi) | ||

| 90 | 100 | 125 | |

| 1/16 | 5.92 | 6.49 | 7.9 |

| 1/8 | 23.7 | 26 | 31.6 |

| 1/4 | 94.8 | 104 | 126 |

| 3/8 | 213 | 234 | 284 |

| 1/2 | 379 | 415 | 506 |

Table 1. Flow rate (in SCFM) for various orifice sizes (Source: Best Practices for Compressed Air Systems) |

|||

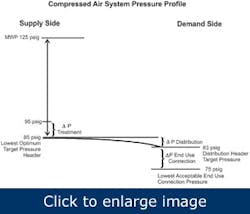

Example system pressure profile

A typical compressed air system pressure profile (Figure 2) shows a lowest acceptable end use pressure of 75 psig. This is the pressure below which unacceptable end use performance results. Calculating backward, the corresponding system pressure differentials are 8 psid for end use pipe connections, 2 psid for the distribution piping and 5 psid for the treatment equipment pressure loss — main air dryer and filter. Therefore, the minimum acceptable operating pressure at the air compressor discharge is 95 psig. Operation at lower pressure results in low pressure at the end use during peak system demands.

Figure 2. A simple pressure profile illustrates how the overall system CONSUMES outlet pressure.

Where it goes

More efficient compressed air system operation can be achieved by reducing the system pressure to a point low enough for good energy savings, but not below the point where critical end uses experience low pressure during normal system events such as high flow transient demands and compressor switching operations.

Pressure reduction using only VSD control

[pullquote]Compressors equipped with a variable speed drive offer the most efficient part-load capacity control available. Suppliers of VSD compressors often argue that, because of the precise control at a constant setpoint, pressures can be reduced to the minimum acceptable pressure. So, why not just reduce the compressor discharge pressure to get the energy reduction benefits of both artificial demand reduction and reduced compressor power? It’s not that easy, the problem being that this strategy leaves the system without stored energy.

Compressed air energy storage

Compressed air energy available in a storage system depends on two factors: storage receiver size and the pressure differential between the storage pressure and the system’s minimum acceptable target pressure. The relationship for this is shown in Equation 1.

Vgas = Vrcvr x (Psto-Ptar)/Patm

where:

Vgas = storage volume (scf)

Vrevr = receiver volume in cu. ft.

Psto = storage pressure (psig)

Ptar = target pressure (psig)

Patm = atmospheric pressure (psia)

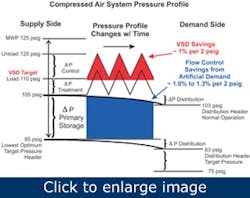

Figure 3. Compressed air block diagram.

The system shown in Figure 3 has a total of 187.2 cu. ft. (1,400 gal) of receiver volume, which is about 4 gal/cfm of the 335 cfm trim compressor capacity. If the compressor discharge pressure is maintained at, say 20 psi higher than the lowest acceptable discharge pressure, the usable storage would be about 258 scf. However, if the trim compressor operates at the lowest allowable pressure of 95 psig, as shown in Figure 2, the storage pressure and target pressure are equal and there’s zero scf of compressed air available from the storage system. If the compressed air storage receivers are at the system’s lowest optimum target pressure, there’s no useable compressed air energy in the storage system.

Need for stored air

Compressed air systems need stored compressed air for many reasons. One common condition that causes random low pressure problems is transient demands exceeding the compressor’s total capacity. A compressed air system is like a bank account balance. If you deposit less than you withdraw, the balance falls. Maintaining a higher balance (pressure) than you need allows you to ride out short duration deficits without causing major problems. Similar to the bank account analogy, setting a VSD compressor at the minimum required pressure doesn’t protect the system from short duration transient demands because there’s no available stored air.

Another condition that might cause a temporary supply deficit is the need to start up more capacity or the failure of an air compressor in a multi-compressor system. When another compressor is called to start, it requires time to respond, perhaps as long as 20 or 30 seconds before it produces compressed air. Air storage is necessary to allow the system to ride through the permissive startup time before the system falls below the minimum acceptable pressure. If the compressor setpoint is already at the minimum, there’s no usable storage.

Usable compressed air energy storage

For the system shown in Figure 3, the useable compressed air volume was calculated at 258 scf. This is the equivalent to the full capacity of one 335-cfm air compressor running for 46 sec. That’s a reasonable and useable storage capacity for permissive start-up and enough to cover small to moderate transient demands.

In a typical system without a pressure/flow controller, this usable energy storage is gained simply by using a compressed air system setpoint 20 psig higher than the system’s minimum acceptable discharge pressure. The air compressor’s average power use will be 10% greater than it would be if the system were operated without any cushion for normal operation. The problem is that without any flow/pressure control, the 20-psig pressure increase is also applied to the demand side of the system. Artificial demand will, therefore, increase by another 10% to 16%.

Use flow control

Flow control valve packages can be called pressure/flow controllers, intermediate controllers, demand expanders or main plant regulators. They all perform the same basic function: to eliminate waste lost to artificial demand and control compressed air energy storage to maintain a consistent pressure supply to the demand side of the system (Figure 3).

Flow control valves applied properly produce a real-time dynamic balance between compressed air supply and demand. When using flow control to separate the system’s supply side from its demand side, the system’s storage pressure can be operated at the pressure required for usable stored energy, while the flow control maintains the system’s demand side at its lowest optimum target pressure.

Figure 4. An operating pressure profile displays the important factors in an integrated manner.

The best approach is to use flow control and VSD to balance supply and demand. The problem with using only flow control is that it doesn’t address the potential savings by optimizing the compressor discharge pressure. The use of a VSD compressor, rather than load/unload or modulating compressors, can achieve this goal. The compressor discharge pressure must operate within a fixed pressure band with load/unload control — in the example, 110 psig to 120 psig (Figure 4).

For systems in the 100-psig range, every 2-psi increase in discharge pressure increases air compressor energy consumption by about 1% at full output flow.

Higher-than-needed pressure imposes another penalty. Raising compressor discharge pressure increases the demand of every unregulated usage, including leaks and open blowing. Although it varies by plant, unregulated usage is commonly as high as 30% to 50% of air demand. For systems in the 100-psig range with 30% to 50% unregulated usage, a 2-psi increase in header pressure increases energy consumption by another 0.6% to 1% because of the additional unregulated air being consumed. In the worst-case scenario, the extra flow could cause another compressor to start.

For a system in the 100-psig range having 30% to 50% unregulated usage, the combined effect of that 2-psi increase in discharge pressure is an energy waster of somewhere between 1.6% and 2%.

Source: The Compressed Air Challenge – Advanced Management of Compressed Air Systems Seminar.

A compressor’s part-load efficiency depends on the width of the pressure band and the storage volume. In general, the wider the pressure band, the more efficiently the compressor will operate. However, the wide band causes higher average compressor discharge pressure, which increases energy use.

Lower average supply side pressure can be achieved using VSD compressor control, if the load/unload compressor operates at a constant set target pressure near its load point. The red shaded area in Figure 4 represents the VSD energy savings achieved by operating at a constant 110-psig target with VSD control, rather than using a 10-psi wide load/unload pressure band.

Rather than setting the demand side pressure 20 psig higher than the system’s lowest optimum target pressure, pressure/flow controls can allow reduced demand side pressure and achieve artificial demand savings of between 1% and 1.3% per 2-psi reduction. These savings are represented as the blue shaded area in Figure 4.

Optimizing the pressure profile

Most compressed air systems require usable energy in storage as a cushion to ensure production won’t fall below the desired target pressure. Those unfamiliar with flow control believe it’s the flow control valve that increases compressor discharge pressure. In reality, it’s the need for usable energy storage that determines the target for compressor discharge pressure. All compressed air systems benefit from an optimized compressor control strategy, and VSD compressors provide good performance characteristics.

To reduce energy use, evaluate the system’s need for compressed air energy storage, map out the optimum pressure profile and implement a good optimal control strategy. You will find for many compressed air systems, pressure/flow control combined with variable speed drive trim capacity is a winning combination.

Tom Taranto is an independent compressed air system professional in Baldwinsville, New York. Contact him at [email protected] or (315) 753-0070. Ron Marshall is a member of the Project Development Committee at the Compressed Air Challenge. Contact him at [email protected] and (204) 360-3658.