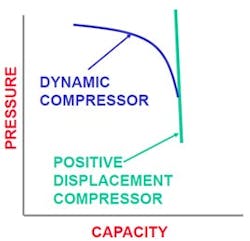

There are two basic principles of air or gas compression: positive displacement compression and dynamic compression.

Positive displacement compression

In positive displacement compression, the air is drawn into one or more compression chambers, which are then closed off from the inlet. The enclosed volume of each chamber decreases through the displacement of one or more moving parts and the pressure increases, compressing the air internally. Once the pressure reaches the maximum pressure ratio, a port or valve opens; the continued reduction of volume in the compression chamber discharges the air into the outlet system.

Positive displacement compression occurs in the following types of compressors: piston, vane, scroll, liquid ring, rotary screw, tooth, and roots blower compressors.

Dynamic compression (turbocompressors)

In dynamic compression, air is drawn between the blades on a rapid rotating compression impeller and accelerates to high velocity. The air or gas is then discharged through a diffuser, where the kinetic energy is transformed into static pressure. Most dynamic compressors are turbocompressors with an axial or radial flow pattern and are often designed for large-volume flow rates. Unlike a positive displacement compressor, which works with a constant flow, a dynamic compressor works at a constant pressure. Dynamic compression occurs in radial (centrifugal), axial, and ejector compressors.

Pressure and flow rate comparison

Positive displacement and dynamic compression are affected by different variables. The following calculations show the influence of factors such as inlet pressure, inlet air temperature, volume flow, mass flow, and pressure ratio on power consumption and performance.

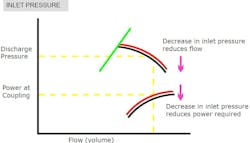

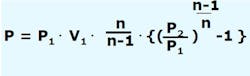

Positive Displacement: Inlet pressure, volume flow, and pressure ratio are the only variables that influence the power consumption in positive displacement compressors. Inlet air temperature and mass flow (density) have no effect on power.

P1: Inlet pressure

V1: Volume flow (not mass flow)

P2/P1: Pressure ratio

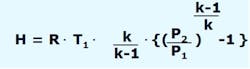

Dynamic Compression: Inlet temperature and mass flow (density) have a direct effect on the power of dynamic compressors.

H: Isentropic head

R: Real gas constant

T1: Inlet temperature

K: Spec heat ratio cp/cv

P2/P1: Pressure ratio

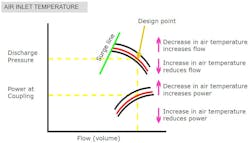

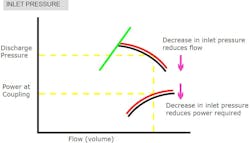

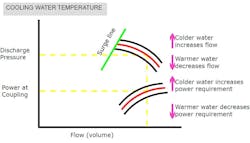

The following diagrams illustrate the effect of inlet temperature, molecular weight, and cooling water temperature on the performance of a dynamic compressor.

As inlet air temperature decreases, flow and power increases.

As molecular weight increases, flow and power increases.

As the cooling water temperature decreases, flow and the power requirement increases.

Selecting positive displacement or dynamic compression

Selection of either technology depends on the application, but there is a rule of thumb: Dynamic compression technology is best suited for base load requirements, while positive displacement compression is better suited to variable load. For larger flows and variable demand applications, a combination of both technologies often helps to reach the optimal usage of compressed air while simultaneously reducing energy consumption.