Infrared contact lenses bring sci-fi vision to real-world engineering

Key takeaways

- Infrared-vision contacts enable power-free night vision, ideal for industrial use in low-light or hazardous environments.

- Color-coded IR wavelengths boost visual data interpretation—helpful for inspection, diagnostics, and quality control.

- Lens tech supports secure data transfer via flickering IR signals—applicable in anti-counterfeiting and smart manufacturing.

- Potential for real-time, hands-free IR imaging enhances safety and precision in engineering, rescue, and maintenance tasks.

Like it or not, we’re all turning into cyborgs. Sounds dramatic, sure—but if you’ve ever panicked over a dead phone battery, you know it’s true. The line between humans and machines is getting blurrier by the day, and let’s be honest: we’re already halfway there. We rely on smartphones like they’re extra limbs, wear earbuds that double as translators, and put on glasses that add digital layers to real life. Tech isn’t just around us—it’s in us. And now, scientists have set their sights on supercharging the humble contact lens.

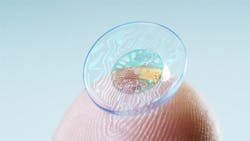

Researchers from the University of Science and Technology of China have developed a groundbreaking contact lens that gives both humans and mice the ability to see infrared light—without the need for bulky night vision gear. These lenses work by converting invisible near-infrared light into visible wavelengths, allowing users to perceive both visible and infrared light at the same time. Best of all, the contact lenses do not require a power source.

The lenses are embedded with specially designed nanoparticles that absorb near-infrared light (800–1600 nm) and emit it as visible light (400–700 nm). These particles are embedded in soft, non-toxic polymers—materials already used in regular contact lenses—making the technology both safe and comfortable for everyday use.

In lab tests, mice wearing the lenses showed clear signs of infrared vision: they avoided infrared-lit areas, their pupils constricted in response to infrared light, and their brains responded as if seeing. Human participants were also able to detect Morse code-like infrared signals and determine the direction of infrared beams—with enhanced performance when their eyes were closed, thanks to near-infrared light’s ability to pass through eyelids with minimal interference.

In a recent quote, Tian Xue, a neuroscientist at the University of Science and Technology of China, said, “Our research opens up the potential for non-invasive wearable devices to give people super-vision. There are many potential applications right away for this material. For example, flickering infrared light could be used to transmit information in security, rescue, encryption or anti-counterfeiting settings.”

Color-coded infrared vision for enhanced spectral differentiation

To add detail to what users can perceive, researchers engineered nanoparticles to convert different infrared wavelengths into different colors—such as turning 980 nm light blue, 808 nm light green, and 1,532 nm light red. This innovation not only enhances spectral perception but also offers future potential for helping individuals with color blindness.

Because light scattered too much inside the eye for high-resolution detail, the team also created an external glass system that uses the same nanoparticle technology to deliver sharper infrared images.

The team recently published their findings in a paper titled “Near-infrared spatiotemporal color vision in humans enabled by upconversion contact lenses.”

Next steps: Improving low-intensity infrared light sensitivity

Currently, the contacts only detect infrared emitted from LED sources. Researchers are now working to improve the sensitivity of the nanoparticles to detect more natural, lower-intensity infrared light.

This innovation offers a lightweight, power-free way to integrate infrared vision into everyday wear. From enhanced imaging in design and engineering applications to new tools for accessibility, this technology opens a wide range of possibilities for fields that rely on advanced optical sensing.

About the Author

Alexis Gajewski

Senior Content Strategist

Alexis Gajewski has over 15 years of experience in the maintenance, reliability, operations, and manufacturing space. She joined Plant Services in 2008 and works to bring readers the news, insight, and information they need to make the right decisions for their plants. Alexis also authors “The Lighter Side of Manufacturing,” a blog that highlights the fun and innovative advances in the industrial sector.