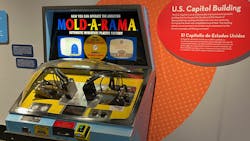

Meet the Mold-A-Rama machine, 3D printing’s older, kitschy cousin

What happens when you combine a vending machine with plastic injection molding and add in a pinch of mid-century flair? You get a Mold-A-Rama machine. If you’re not a Midwesterner, then you might not know what I am talking about. But for those of us who grew up in Illinois, Minnesota, Michigan, or Wisconsin, Mold-A-Rama holds a special place in our nostalgic hearts. Every time I went to the Brookfield Zoo or the Field Museum of Natural History, I would drag my parents to the closest machine and beg them to buy me a tiny plastic statue. The real magic, however, was in watching the figurine being created right in front of our eyes in less than one minute. This became many kids’ first introduction to manufacturing.

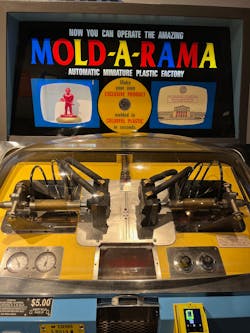

Here's how it works. First, insert your money into the machine. (Back in my day, each statue cost $1. The current price per figurine is $5. Thanks, inflation.) Next, two thick aluminum plates are pushed together, creating the mold. Polyethylene pellets, heated up to approximately 250°F, are then injected into the mold, while a blast of air works to hollow out the piece. Unnecessary plastic is removed through a drainage hole in the bottom of the mold. The statue is then cooled and hardened before the plates pull apart and the piece is pushed into the pick-up box.

The Mold-A-Rama machine was invented by J.H. “Tike” Miller and debuted at the 1962 Seattle World’s Fair. The initial batch of models included a monorail, a Buddha, and a 3D sculpture of the Fair’s logo. The 1964 World’s Fair in New York City, however, made Mold-A-Rama a household name. It is said that as many as 150 machines were installed over the Fair’s two-year timeframe, and models included various dinosaurs, Disney characters, animals, and presidential busts. After being featured at the Montreal World’s Fair, Expo ’67, Mold-A-Rama machines became staples at museums, zoos, amusement parks, and anywhere that sold souvenirs.

The mid-century machines remain popular to this day. According to the current owner, one in 10 people who pass a machine buy a model, and the company uses about 640 55-pound bags of plastic pellets a year. Each Mold-A-Rama machine hold a gallon of hot liquid plastic and can produce up to 150 figures a day.

If you’re looking to experience the magic of a Mold-A-Rama (or its cousin, the Mold-A-Matic) for yourself, here is a list of 10 locations where you can see these marvelous machines in action. If you happen to be in the Chicagoland area, take a trip to the Museum of Science and Industry and check out their latest exhibit, Mold-A-Rama: Molded for the Future.

About the Author

Alexis Gajewski

Senior Content Strategist

Alexis Gajewski has over 15 years of experience in the maintenance, reliability, operations, and manufacturing space. She joined Plant Services in 2008 and works to bring readers the news, insight, and information they need to make the right decisions for their plants. Alexis also authors “The Lighter Side of Manufacturing,” a blog that highlights the fun and innovative advances in the industrial sector.