Preventive maintenance like the military: Part 2

This is Part Two of a two-part article on performing preventive maintenance like the military. The purpose of the article is to demonstrate how to develop a preventive maintenance (PM) program for your organization using principles similar to those employed by the United States Army. Part One appeared in the June 2022 issue of Plant Services, and is available online at: https://plnt.sv/PM-MILITARY-01

Develop the training

The Army uses a phased approach to train personnel on each piece of equipment as follows:

- classroom (crawl)

- hands-on (walk)

- testing in classroom and field as applicable (jog)

- perform PMs on the job (run).

Military training uses a structured process that covers task, condition, and standards along with performance measures for each PM. Training is structured and consistent throughout the military (not including local Standard Operating Procedures or SOPs). PM training and certification allow seamless transfers from unit to unit. Some additional training is carried out for site-specific requirements, such as temperature, altitude, and local regulations. Such training enables the soldier to go from the street to service in six months (although some skills take longer). This provides a good model for industrial sites to use to develop both craft task training and PM training that is consistent and can be used at multiple sites.

The classroom PM training would be set up using tasks, conditions, and standards. Figure 1 shows a side-by-side comparison of tasks, conditions, and standards for the protective mask and a PM for changing oil on an over-hung pump. From the standards in its technical manuals, the military develops a performance sheet to test the soldiers after the training.

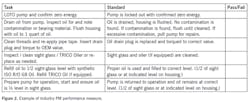

Using the same task, conditions, and standards format for an industrial PM (changing oil in a pump), the PM performance sheet would look as shown in Figure 2. The training would include classroom instruction, hands-on training in the classroom with an actual pump, and then a performance evaluation in the field, evaluated either by the instructor or by a qualified craftsman chosen to evaluate training tasks.

This process is a good model to use to develop a training program for each PM at your site either to train new personnel with no skills (part of a journeyman program) or re-certify current personnel. A recertification program is a necessary part of the PM process to ensure your personnel remain qualified to perform the work in your organization.

Starting with your critical equipment, you can review the PMs to determine if they are set up correctly. Standardize the PMs as needed, validate with your senior or experienced personnel, and then develop training for each PM to cover all skill levels of your organization. One training course can cover all personnel for that PM, but the more skilled craftsmen should be re-qualified on the hands-on or field execution of the skills on a periodic basis. I have used an interval ranging from one to three years, depending on the criticality and difficulty of the PM.

Optimize the PM program

Keeping track of the PM work performed on equipment is important for several reasons. One is to ensure compliance with respect to the PM program. Another is to review and optimize the PM program itself. The military uses forms to record the data and digitizes that information to assist in recordkeeping and for ordering repair parts. I have worked at facilities where PMs are performed, but no records of the work or issues found were kept, making it nearly impossible to gauge the effectiveness of the PM program.

An additional benefit of tracking PM work done is being able to establish the proper stocking levels of spare parts based on actual work performed. Tracking what part (object) was worked on, what the issue was (damage), and what the cause of the failure/issue was (cause) over time will provide valuable failure data and information to help optimize the process.

Continuous improvement will lead to PM optimization. The reason for optimizing your PM program is to ensure reliable operation of your equipment. If your reliability is not improving and the same failures are occurring, you may want to consider the following in your program:

- The PM interval may be too long, and potential failure is not being identified during the PM, so failures are occurring before the next PM.

- The PMs are not set up to identify the potential failures by asking the wrong questions, or looking for the wrong potential failure mechanisms. Object damage cause (ODC) codes from repair WOs will assist in this review.

- PMs are not repeatable or consistent and are performed inconsistently by different technicians.

- The wrong tools are being used or the technician is using tools improperly.

- Human error is induced into the equipment during the PM.

The ODC information data from PMs and work orders can provide insights on reliability and fitness for service of the equipment, allowing for reliability improvements.

Here are some actual PMs I reviewed and modified to make them more specific, repeatable, and effective. Figure 3 shows a PM assigned to an instrument technician to perform on a level switch on a sump pump. This PM is used on more than 100 pumps at various sites by eight different technicians. From discussions with the technicians, I learned there were several different methods used for performing this PM. The worst case was from one technician who said he would check the set point of the system in the PLC, and the PM was done.

The review of the PM provided the following:

- the PM was not performed in the same manner.

- the results of the PM varied among craftsmen.

- many key objectives of the PM were missed based on the interpretation of the PM.

I discussed the goal of the PM with the technicians, and we determined the following goals:

- Check the functionality of the transmitter.

- Check to see if the pump:

• starts when required

• has high level indication

• initiates high-high level test and shutdown sequence

• stops when required; doesn’t run the pump dry

• points are within a specified tolerance.

- Perform visuals on the system for wear and tear.

- Ensure a repeatable process.

- Record the results.

From the above results, we reworked the PM and developed a new PM form. The new form had information on the transmitter to allow the technician to verify that it was the correct transmitter, and to determine if the transmitter has been replaced since the last PM. Next, there are four level checks (not one) performed, which are actual level filling checks to confirm the functionally of the transmitter, pump, and PLC and ensure they are all working together. There are also tolerances for each check with instructions on actions to perform if there is a functional failure. Finally, there is a section to place the system back into operation.

Once this PM was reworked, we field-trained the technicians and tested the procedure, made some final adjustments, and then placed the PM into our CMMS, allowing us to perform the PM on a tablet with results uploaded into the CMMS upon completion.

During the field verification of this PM, I noted that one of the supervisors kept finding the transmitter he was working on in a failed condition. As I observed his actions, I noted he was using the test equipment incorrectly. I asked a senior technician I trusted to assist the supervisor on the correct use of the test instrument, allowing the transmitter to pass and the PM to be completed. Why did I have the supervisor performing the PM in the field? By being part of the process, including performing the PM, the supervisor will be more in tune with the work the personnel perform, and the bonus was that I determined the need for additional training on the test equipment.

PM program review and grass roots setup

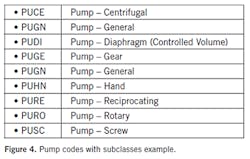

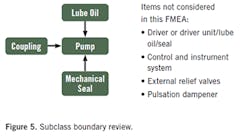

If you have a PM program you want to revamp, or no program at all, a good place to start at is with an equipment class versus PM comparison. First, sort the equipment into classes of equipment along with their criticality. Next, for each class of equipment, sort by subclass. The example in Figure 4 shows pump codes and the subclasses. For each subclass, review the boundary for the analysis (see Figure 5). Next, the different failure modes are reviewed, along with the severity and consequences of each failure, and PM/PdM strategies are developed to reduce the severity and/or the occurrence of the failures.

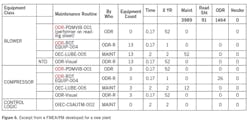

Figure 6 shows an example from a grassroots PM program developed at a new site. This example shows only 3 out of 43 equipment classes with a total of 67 PM/PdM routines. There were close to 4,000 hours of work assigned to maintenance and more than 1,500 assigned to operations. All this work needed to be set up in the CMMS, including training and field verification. Due to this being a new program, a PM optimization was performed after one year of operation.

Although this is an example at a new facility, this same process can be used to evaluate any existing program. By organizing your equipment by class and subclass, performing an FMEA on each class and subclass, and developing the corresponding maintenance and operations routines to address the failure modes, a structured review can be performed. From this list, we can determine training needed for the PMs before beginning or continuing the program. As the PMs are performed and data are captured in the CMMS, we can then perform a PM optimization.

A PM optimization is an essential part of a PM program. Without a review of our PM program, how do we know if it is effective? Some ways to measure PM effectiveness is through the following KPIs:

- MTBF (mean time between failures) or MTBR (mean time between repairs)

- preventive maintenance vs. breakdown labor hours (follow-on work)

- review the comments from PMs: Are there issues being found?

If your MTBF/MTBR is not improving, you should review the failures of the equipment to determine if PMs/PdMs can reduce the number or severity of failures. You should also review the follow-on work orders from PMs and the comments and observations about the PM work being performed. If you conduct a review and your current PMs are not developing follow-on work or there are no comments listed on your PM forms after the work is performed, you have issues with your PMs.

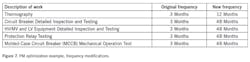

Now let’s review two examples of PM optimizations performed at different sites. The first example will focus on the electrical side (although the optimization covered the entire PM program). A review of the program discovered some PMs had been set up to benefit the contractor performing the work, not the company or the equipment. Thermography was being performed on electrical equipment every three months, but the hands-on PMs were performed on the equipment regardless of the thermography results. Part of the review included the changes shown in Figure 7.

These changes in the electrical area alone resulted in a reduction of 21 full-time equivalent contract employees. Further review and PM modifications resulted in a reduction of 2,210 mechanical tech hours, 2,683 electrical tech hours, and 853 instrument tech hours. In general, the PM program at this site involved working on the equipment. The review reduced the overall PM program by 50% and provided focus on the work that needed to be done. We modified the remaining PMs that were generic and created specific and focused plans that were mapped back to the failure modes of the equipment. The process we used was to develop a list of equipment by class, and list the PMs assigned. Next, we mapped the tasks back to applicable failure modes and removed tasks that were not needed. We also added tasks to PM or added PMs to ensure all feasible failure modes were covered by a PM.

At another site, we reviewed the current PM program and were able to reduce the PM work by more than 70% due to unnecessary work and to re-focus the remaining work on applicable failure modes. For example, pump PMs had more than 94% of the work removed because it was unnecessary. One 12-month PM for all pumps was to perform an alignment check.

Although the facility had an active vibration condition monitoring program that would identify misalignment, they ignored the vibration program and would check alignment of all pumps on an annual basis. This site was another example of where most of the PM work being performed was unnecessary and had been added over the years without a proper review of the system. Both examples show the need to optimize PMs to ensure they are focused on failure modes, and they highlight importance of a review process to ensure the PMs are fit for purpose.

Leadership

Finally, an organization with an excellent PM program will still fail in execution without the proper leadership. All successful PM programs require engaged, hands-on leadership to support the program and the optimization process. Without committed and engaged leadership, the PM program will be marginally functional or even ineffective.

Leaders should spend up to 75% of their time with their maintenance techs. Without being in there where the work is being done and understanding what the technicians do on daily basis, how can a leader provide true direction and motivation and understand the issues that confront the technicians? Leaders can only lead by being involved at the point of action, not from the office.

This story originally appeared in the July 2022 issue of Plant Services. Subscribe to Plant Services here.

Craig Cotter is an engineer with more than 30 years of experience in refining, chemical, and E&P organizations in the areas of reliability engineering and maintenance management. He was responsible for setting up training, certification, and qualification processes for millwrights, pipefitters, and boilermakers at a refinery and setting up formal training programs for non-hourly personnel at several sites. He has a BS in Mechanical Engineering from the United States Military Academy, West Point, NY, and an MBA from Lamar University, Beaumont, TX. He is a retired U.S. Army Colonel, Infantry, with 20 years of active and reserve service.

About the Author

Craig Cotter

P.E., CMRP

Craig Cotter, P.E., CMRP, is a mechanical engineer. He has more than 30 years of experience in reliability engineering and maintenance management. Cotter has a B.S. in mechanical engineering as well as an MBA. He is a retired U.S. Army Colonel. Contact him at [email protected].