Money in your pocket: Fix your compressed air system leaks

Using compressed air to provide power to plant production equipment is quite costly because you must supply the compressor with about 10 times more energy than what you typically get out of the machine. Air compressors produce mostly heat, with only about 10% to 15% of the energy remaining to use for compressed air powered applications. Additional losses occur as a result of drying equipment, pressure losses, and leakage, all reducing the amount of compressed air available to the plant.

Studies have shown that an average of 25% of all compressed air produced is lost because of system leakage before it ever gets to the final end use. In extreme cases, more than 80% of the air that the compressors produce is lost through system leakage. Let’s now examine further the cost of system leakage as well as things you can do to find and fix leaks and the kinds of energy savings that plants have achieved by tackling their leaks.

Leakage costs

A typical fully loaded air compressor running at about 100 psi will consume between 17 and 22 kW per 100 cfm. At 10 cents per kWh, this would mean the cost of the compressed air would be about $1.70 to $2.20 per hour of operation for every 100 cfm of constant flow. If the compressor is never turned off, running 8,760 hours per year, this 100 cfm flow – about the equivalent to a 25 hp compressor – would cost between $14,900 and $19,300 a year in electrical charges to run. Further costs would be incurred in maintaining the compressor because of this operating time.

If you need only 100 cfm and your leakage level is 30%, you will have to produce 130 cfm of compressed air to account for the losses. This would increase the electrical cost of producing the air to $19,200 to $25,000 per year.

For systems operating less than full time, the annual energy would reduce proportionally. For example, operating only 4,500 hours per year would reduce the energy consumption by 48% but not necessarily reduce the cost by the same percentage. If the energy bill has a demand charge component, the peak consumption would lock in part of the electrical costs. Note that this example of reduced operating costs as a result of reduced operating hours is a hint of a possible strategy to reduce leakage costs – we’ll discuss this more later.

Assessing leakage levels

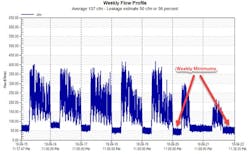

Assessing the general level of compressed air flow during nonproduction periods can be a good way to gauge the potential of reducing leakage. If you are lucky enough to have a main flowmeter on your compressors (if you don’t have one, get one!) and your plant production is shut down at certain times during your production cycle, you can get a general idea of your potential leakage flow by recording the flow-meter readings over the production outages. Figure 1 shows a flow profile in a shift-oriented fiberglass parts plant. Upon inspection of the data, we can see that the plant minimum during weekends is 50 cfm, suggesting there could be up to 50 cfm in leakage.

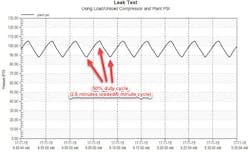

If there is no flowmeter installed, things get more difficult, but it may be possible to roughly estimate the nonproduction flow based on the duty cycle of the running compressor if it is running in load/unload mode. (If you have more than one compressor running, you probably have big leakage problems.) Figure 2 shows an example of this: A compressor rated for 1,000 cfm is loaded during Sunday production shutdown 2.5 minutes out of every 5-minute cycle (50% duty). This equates to approximately 500 cfm nonproduction flow, most of it leakage, but some caused by factors such as compressed-air-powered pain agitators and the pneumatically controlled HVAC system for the plant offices. Fortunately, this plant did something about its leaks.

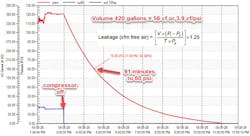

For a system running with modulating compressors, a receiver draw-down test can be done. Before the test, the total system storage volume is carefully calculated by measuring all of the storage receiver capacity and piping volume (for all pipe 2 inches or larger) and then using the formula in Figure 3 to calculate leakage during a special receiver draw-down test. During the test, the running compressor is stopped temporarily and the pressure is allowed to fall to half its normal value. The time it takes for the pressure to drop determines the cfm flowing at that time.

If the compressor is a VSD-style, observation of the compressor’s rpm can help calculate the percentage capacity being used during nonproduction using a simple ratio. For example, if the compressor full-load reading is 3,100 rpm and it is running at 1,000 rpm to feed nonproductive load, then the percentage flow can be estimated at 1,000/3,100, or 32% of the compressor’s capacity.

For systems that run 24 hours a day, 7 days a week and cannot shut down, leakage estimates can be difficult. If a section of the plant can be isolated from the main system, then leakage estimates can be made during nonproduction hours by isolating sections and observing the change to the main flowmeter during the operation. If this is not possible, then the only option is a complete plant leak detection audit with an ultrasonic leak detector.

Ultrasonic leak detection

When compressed air escapes from a pressurized vessel, it emits not just an audible hissing sound but also inaudible frequencies that the human ear can’t detect. Ultrasonic leak detectors convert these frequencies to sounds the operator can hear but block the low-frequency production noises that might make leakage inaudible in a busy plant. This allows the operator to home in on compressed air leaks big and small and find other, potentially wasteful compressed air uses.

There are many manufacturers of ultrasonic leak detectors, with leak detector prices ranging from $500 to more than $5,000, depending on the meter features installed. Thorough use of these meters in industrial plants will find almost all of the significant compressed air leaks.

Using the leak detector to estimate flow consumed by each leak is tricky. Some manufacturers provide a table of decibel values that correspond to an estimated flow if the leak is measured a certain distance away from the detector. Experience shows, however, that leakage levels are often overestimated using this method, so it’s best to be conservative in doing the calculations. If a main flowmeter exists, it’s a good idea to check whether the total flow found by leak detection matches or is less than the main flow to the plant.

The best practice when finding leaks is to fix them immediately. If this is not possible, use of manufacturer-provided leak-recording apps that can run on a smartphone is very convenient. A number of leak detector vendors offer these programs, which can be used on a smart device you carry in your pocket or recorded in built-in memory in the leak detector itself. These programs allow you to record leaks, estimate flow, and record a photograph or two for later identification. At the end of the audit, the apps can produce a report of all of the leaks for the maintenance staff’s benefit and in some cases allows the leak repair progress to be tracked. Flagging the location of leaks with paper tags also is recommended to make it easier to track leaks down come repair time.

Leak detection experiences

A variety of industrial sites have achieved impressive results through their leak detection and correction efforts. Some examples:

Foundry audit. A railway wheel foundry was replacing its air compressors, and the regional power utility was providing an incentive for an upgrade to a more-efficient type of compressor. The utility support engineer had identified, through measurement on a main flowmeter, that there was 1,000 cfm of flow during nonproduction shifts on holidays. The reduction in power and energy for a recommended leakage reduction of 200 cfm was estimated at 38 kW, or 333,000 kWh per year. This had the potential to save $24,000 in energy costs per year and generate an additional $48,000 in incentives that would be used to help finance the compressor purchase. The customer agreed to this and attempted to repair as many leak as it could by simply detecting leaks heard with the naked ear, but after two weekend repair blitzes, the leakage flow had been reduced by only 60 cfm. An auditor using an ultrasonic leak detector was called in to spend a day combing the plant for significant leaks. About 30 significant leaks worth about 50 cfm were found in the first pass. But a second sweep of the plant found a very large leak on a dust collector manifold that was partially masked by its location near the plant roofline in the middle of a noisy production area. The leak was isolated for special testing, and the auditor found that this one leak accounted for 550 cfm of flow, worth 867,000 kWh and equivalent to $66,000 per year in electrical costs.

The leak detection exercise found not only leaks but also inappropriate uses of compressed air. Cooling of cabinets with compressed air, faulty desiccant air dryers, and failed drains also were found – issues that, when corrected, could yield $15,000 more in annual savings.

Aerospace. As in the case of the foundry, an aerospace plant was wanting to access a power utility incentive program to help finance their production capacity upgrade. Main flowmeter data showed about 360 cfm of leakage on the weekend when no personnel were working in the plant. A leak audit was conducted, and shortly into the exercise the auditor noticed a dust collector making strange noises. On investigation he discovered a blast valve had failed in the open position, allowing a high flow of air to escape, for no useful purpose. Further testing found 115 significant leaks in the plant and various outbuildings. Repair of the faulty blast valve reduced the compressed air flow during all hours by 160 cfm, as confirmed by the main flowmeters, allowing one compressor to be held off during the main shift. Estimated savings for the valve repair alone are $20,000 in electrical costs. Further savings will be gained as the other significant leaks, estimated at 100 cfm, are repaired.

Mining. A large mine has a huge compressed air system consuming between 3,200 and 4,000 kW of power during normal operation. The powerhouse superintendent had flowmeters installed that showed the main flow of compressed air and also section out the flow to various separate production areas. Occasionally a large spike in the power used by the air compressors happens, indicating that something has gone wrong with the compressed air system. The increase is usually the result of a piping failure underground due to the advanced age of the network. Whenever a failure occurs, the flowmeters allow the compressor operating personnel to detect where the excess air is being used so remedial action can be taken. The superintendent also tracks the long-term increase in compressor power and sends out a call to action whenever the flow reaches what he feels are excessive levels. Figure 4 shows that his efforts in achieve savings and that over time leakage levels climb until more action is required.

Tractor plant. A compressed air assessment was conducted at the tractor plant mentioned previously after a compressor failure. This plant was operating only one shift of full production with a small second shift, where only a few production machines were running, yet the compressor ran full time, nights, weekends, and holidays. Plant flowmeters showed 500 cfm of flow when no personnel were in the facility. Flowmeters also showed that the average plant flow was only 577 cfm when production was included. A quick calculation showed the nonproductive load was 87% of the average – a very poor result that was embarrassing to the maintenance staff.

Based on this information, the maintenance manager set out to reduce the leaks. A millwright was hired whose only job was to find and fix leaks. After four weeks, the leakage flow had declined to 400 cfm, a 20% reduction, which would save a projected $12,000 per year. But the big savings came when the maintenance manager started looking into what assets actually needed air at night and on weekends. He found that he could supply his office HVAC system with a very small compressor and turn off his air agitators, thus allowing him to completely shut down his main compressors when there was no production. This act alone saved 45% of the original compressed air energy consumption and significantly reduced compressor run time, thereby reducing maintenance costs.

An important step in addressing plant leaks and compressed air waste is to measure your nonproduction flows. There are a number of ways to do this, from using a simple timer test to installing and taking advantage of a network of flowmeters. Ultrasonic leak-detection instruments often prove highly valuable in locating small and large leaks and identifying other compressed air waste that can be addressed through equipment repair. It might be time to take action on your system.