Smoothly running industrial bearings keep manufacturing processes moving and producing. Bearings are the joints in the process, carrying the body weight and production load. They remain invisible until wear eventually brings them down – and then they are painfully visible, requiring attention and forcing a person to sit or a process to stop.

Without effective bearing motion, a machine shaft can fail and the machine can break down. But there are ways to prevent improper wear on bearings and increase their life, thereby increasing process availability and improving the safety of your environment. There are also indicators of bearing failure to look out for.

Whether or not your facility has experienced bearing failure recently, you can be sure that bearings are busy being worn down during every second of process operation. Consider these six actions you can take now to prevent a bearing — and process — failure.

1. Choose the correct bearing design

Perhaps the most basic determinant of proper bearing operation is choosing the right bearing design for the application as defined in the original equipment manufacturer (OEM) documentation. The bearing must be able to handle the load that is being applied to it. For example, bearings requirements for belt-driven equipment are different from those for in-line equipment.

Also, it’s vital to choose the most appropriate bearing size, or you’ll risk premature wear and eventual failure of the bearing. Again, the size will depend upon the machine and the manufacturer’s recommendations. When replacing the bearings, replace what was originally used in the machine unless an issue has developed in the machine that requires engineering to be involved.

2. Store bearings actively

Today, most facilities minimize the spares they keep in their stores. Through predictive or preventive maintenance, these facilities can detect potential failure early enough to be able to correct, order, and replace bearings before a machine goes down. This just-in-time ordering means that machines and bearings do not need to sit on shelves.

But sometimes bearings and machines with bearings must be maintained in the facility stores. In these situations, although they’re resting on shelves, the bearings still can experience vibration because of the facility operating around them. Those bearings should be stored actively – in other words, they should be rotated or spun occasionally. Without occasional rotation, they can experience false brinelling, in which bearings etch a pattern into the raceways because of vibration. This can result in premature failure.

3. Install bearings properly

Sheer force does not work in bearing installation. Heat, however, often does. For example, in roller element bearings, the inner race fits tightly if it is cold during installation. That is because heating the inner race expands it to fit more easily during installation.

After completing installation according to the manufacturer’s instructions, give the bearings a good flushing and cleaning out with lubricant. Finally, apply the proper amount of lubricant before the machine is used. This leads to the next important activity in improving bearing life: lubrication.

4. Lubricate bearings according to manufacturers' guidelines

When facility personnel properly lubricate bearings, they extend the life of the bearings and machinery. Without enough lubrication, the balls, retainers, and raceways will have metal-on-metal operation, and friction will wear down the bearings. In an overlubrication situation, heat cannot be dissipated, and wax will build up, making the bearing stick and not move correctly. Both conditions eventually reduce the efficiency of a machine and a process.

Keys to proper lubrication include using the correct lubricant quantity and viscosity (as determined by the machinery OEM) for the load, avoiding extreme out-of-range temperatures, and preventing ingress of dirt or other contaminants.

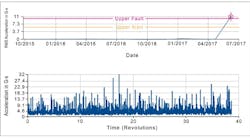

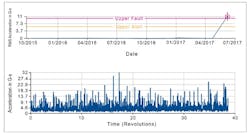

A facility can monitor lubrication conditions by monitoring stress waves, which are created by friction. Some industry tools can detect short-duration, high-frequency stress waves and produce graphs indicating their presence. Graphed data at right show a bearing in which the seal had been leaking and the lubricant washed out. In these underlubricated conditions, the software-generated graph shows the force of impacts. Notice that the impacts are random and that some are as large as 32G-s. Also notice in the top graph that the impacts began suddenly to reach the upper fault level. These are signature characteristics of underlubrication.

When improperly lubricated, a rolling element in a bearing might cause the inner or outer race to deflect and spring back, creating a stress wave. New technology can parse out the frequencies to see the stress wave, leading to the early detection and elimination of bearing anomalies.

A facility can also use ultrasonic detection to listen to bearings and hear when the lubrication is sufficient to minimize friction.

5. Align machinery precisely

In manufacturing environments, maintenance teams want to get machines repaired and back into service as quickly as possible. But the job is not complete without precision machinery or train alignment. Proper shaft alignment will help maximize the reliability and availability of production assets, extending machine life in some cases from months to years.

Without precise alignment between components, the bearings of the machine or train will experience abnormal wear. Flexible machinery couplings will adequately absorb some amount of misalignment, but this is not true for machinery bearings, which will experience premature wear. A misaligned machine train also will experience high energy consumption and a decrease in efficiency.

The best practice is to be proactive by checking alignment before putting the machine or train into operation correcting any misalignment detected before starting up operation. Then, document the alignment before operation so that the maintenance team can later compare day-to-day operation against the baseline startup.

Laser alignment systems can make sure components are set correctly before putting them back into action.

6. Balance equipment well

Look for imbalance in machinery. If a fan is out of balance, for example, the bearings will experience more load and shorter lives. The problem can be found through vibration diagnostics equipment or with a trained vibration expert analyst. Analysis of collected data can be used to determine whether the machine needs precision balancing or perhaps a thorough cleaning to remove material buildup. When a machine undergoes maintenance, make sure that it is rebuilt accurately and that components are reinstalled correctly (mark each component prior to removal). It’s not uncommon to detect an imbalance condition after maintenance or a rebuild.

Monitoring trend data can help an analyst determine proper corrective action for an imbalance condition. Normal wear and material buildup will be reflected by a slow, steady increase in amplitude over time. If a piece of the equipment has broken off or if the machine was assembled incorrectly, then the trend will show a sudden increase in amplitude.

Regardless of the root cause of the imbalance condition, the additional forces applied to the bearings will lead to abnormal wear and premature failure.

Additional diagnostic tests

After putting into place these six practices, if you find that you must continue to replace bearings every few months, perform a root-cause failure analysis (RCFA). If, for example, you see that the roller element bearings continue to have unusual wear patterns, reach out to the bearing manufacturer so that they can examine them and tell you whether the lubrication was sufficient for the load the bearing was trying to handle.

Without being destructive or invasive, vibration analysis gives the most detail about what is happening inside machinery by detecting bearing wear, installation error, and other mechanical problems. Supplemental technologies can ferret out issues that might be indicated by the overall vibration analysis.

Brian Overton is sales development and training manager at Emerson.

IR thermography will help determine whether the issue relates to conditions that are too hot or too cold by indicating the temperature in the couplings and bearings.

Oil analysis runs samples of the lubricant or oil to determine whether there are abnormal wear particles or contamination-causing issues in the bearing. This is also a good way to determine if there has been any contact with a sleeve bearing by looking for babbitt in the sample.

Whether done in-house or by third-party experts, bearing analysis is an important part of a facility’s installation and maintenance procedures for short- and long-term returns on investment.