Throughout my years in manufacturing maintenance, I have faced situations in which my peers and managers above me have had no understanding of the value of maintenance. For a long time, I blamed them. As I have matured in my management journey, I have come to understand that it is my job to educate everyone, not just those for whom I am responsible, about maintenance's true worth.

Example 1: Cost avoidance related to a vacuum pump failure

When a vacuum pump failure occurred on a production line, the total cost associated with that failure was $9,523:

- 1 vacuum pump = $2,700

- 3 hours of downtime = $2,250

- 1 hole in the wall repaired = $500

- Emergency weekend work = $4,073 (four support techs were scheduled, multiplied by two shifts to run new wire and fix conduit. This 64 hours of work multiplied by $57 per hour = $3,648 in labor + $425 in materials)

By contrast, early detection of a similar vacuum pump failure incurred a total cost of two hours of downtime, which is equal to $1,500. (The pump from the manufacturer was faulty, so we will receive a replacement free of charge.)

This is a cost avoidance of $8,023.

The awareness gap results from management having limited or no knowledge of the maintenance function and its ability to contribute to the manufacturing process; and maintenance personnel, managers included, having limited understanding of the business side of manufacturing. The result is that management and maintenance often are often unsure how they together contribute to the company's success.

Your company's maintenance attitude

When I ask managers or hourly workers what their organization's perception of maintenance is, I tend to get the same types of responses. I hear things like:

- Maintenance is a cost center

- Maintenance is a necessary evil

- Maintenance is the cost of doing business

- Maintenance personnel are firefighters

When asked to define maintenance, they offer words such as fix, restore, replace, recondition, patch and rebuild. I'd say these are reactive definitions of the word.

What is maintenance? Maintenance is to maintain or the act of maintaining. The basis for maintaining is to keep something in a specific state or condition – that is, to keep it (the asset, in our case) in an existing state or preserve it from failure or decline. There is a world of difference between this definition and the words and functions normally recalled by most people who are “knowledgeable” about the maintenance function.

The best way to change the perspective is to show the entire organization how it is that maintenance provides value. To keep things simple here, let’s focus on three types of value: convenience, process improvement, and financial value.

- Convenience is sold through a demonstrated or statistical approach to prove that a plant will be safer and will produce higher-quality product, resulting in less rework. Greater production efficiency means lower costs; lower costs gives us marketing advantage; marketing advantage and enhanced competitiveness can promote job security. You empower people to do what they know to do by providing the proper tools and removing obstacles to their getting it done.

- Process improvement is sold through less downtime. This means running to plan, which makes the production manager look like a superhero. Better asset use improves capacity, which means more volume, more profit, and more recognition. Also, less downtime results in less frustration, raising morale and helping to drive culture change.

- Financial value is sold through the freeing of cash flow, reduced costs, and higher profits. These all translate into two things: higher stock value and more capital for reinvestment into the company.

Manage in three directions

There are three directions in which a manager has to manage: up, out, and down. Managing up, out, and down means sharing your vision for your department and educating everyone you can on what true, proactive maintenance is.

I have to educate the upper management, my peers, and those I am entrusted to manage. It is your responsibility as well (no matter your title). As a maintenance manager, I have not just a responsibility but an obligation to educate those around me on the maintenance function and the ways that we add value. So, let’s look at the three ways.

Let’s start with managing those we are entrusted to manage. Although all three of these areas are intertwined and affect everyone, the best way to sell this group is through convenience. Going home to their family with all limbs intact, not having to endure a day of hard labor, and striving to be the best are great ways to motivate this group. Convincing this group takes execution of low hanging fruit for quick wins. The goal is to gain their trust and buy-in into your system with the expectation of becoming world class.

You have to empower your employees to manage programs such as condition monitoring, MRO, planning and scheduling, etc., with you by their side as a coach. Also, one of my goals is always to set the standard for the organization in whatever we do. If you can do this, you will not have someone else determining how you are going to execute your maintenance strategy. The easiest way to get your vision squashed is to have another maintenance manager within your organization determining what your best practices should be, especially when they are contradictory to proactivity in maintenance.

At the peer level, the key is to try to develop a partnership. With that, you show value by showing them what can be if they buy-in to your system and partner with you in driving process improvement. What any production manager wants is process stability with reduced variation. One example would be defect elimination. Offer to train their employees and them as well as to how to drive defects out of the system. Show them statistics and case studies as proof that the system works.

Example 2: Raise profit margins through efficiency gains for "product XYZ"

The total financial picture is a complicated one, but bear with me in this example for the sake of simplicity.

We need to produce 800 cases of product XYZ, and run eight-hour shifts. Optimized, we can produce 10 cases an hour, but because of system defects causing minor stops and breakdowns, we run only five cases an hour. We have scheduled to run this product over the next two weeks. At the current run rate it will take us a month to run this product.

It takes five employees who make $10/hour to run this line. To hit commitment, we are going to have to run 12-hour shifts and weekends.

The product and material cost for 800 cases is $8,000.

- There are five cartons in one case.

- Material cost per case is $10.

- Cost per carton is $2.

At current run rate, labor cost without employee benefits is $11,200

- 80 hours straight time x 5 employees x $10/hour = $4,000

- 64 hours overtime x 5 employees x $15/hour = $4,800

- 24 hours double time x 5 employees x $20/hour = $2,400

Labor + material total cost is $19,200.

Total cost per case is $24, and cost per carton is $4.80. We then sell the case at $25, making our profit $1 per case.

By contrast, if we eliminate the defects from the line by restoring equipment and create procedures to make sure we do not go backward, we can run at operator design rate, which is 10 cases per hour.

Total cost of material and labor for ODR is $12,000.

- Our material costs stay the same: $8,000.

- If we run only on straight time to hit our commitment, our cost incurred from labor is $4,000.

Total cost per case is now $15, and cost per carton is now $3. Our profit is now $10 per case vs. the $1 per case at the previous rate.

If you extend that scenario over a full year, 20,800 cases a year produced on the line in each scenario, it looks like this:

- Current run-rate profit = $20,800/yr

- New (restored) run-rate profit = $208,000/yr

I do not know any manager who wouldn't want these results. I truly believe that the problem is that there is a huge knowledge gap about what kind of return on investment maintenance can provide.

A word of caution: Make sure you have the knowledge level to launch a system like this that will be sustainable. If not, seek help from outside resources. All of us have already been through 46 different flavor-of-the-month operations systems. What they do not need is another one. Understand the gaps that separate you from where you want to be. Also, don’t be a finger-pointer, be a solutions provider.

The first two directions to manage are fairly simple to understand and do. Managing up is normally where the wheels fall off. What happens in most organizations, because the maintenance manager does not understand this piece of the equation, is that they do not get their way with an initiative they want to roll out or a project they think will help them win over their department. They then become frustrated and use the management’s lack of understanding as an excuse as to why they will never succeed in their current situation.

What needs to be understood is that the upper management, 90% of the time, doesn’t understand what maintenance does or what they should or shouldn’t do. These managers know only that maintenance is a cost center. They normally think that maintenance is needed to keep things running, not make them a profit. This is where we can work to change that mentality. Value to the upper management is sold in dollars. If you can convert everything that you want to do to dollars, you will have a higher success rate at selling your ideas to the organization.

Will they say yes every time? No. Your job is to make it a difficult "no." We all seem to know that maintenance is a key part of any organization, but we really struggle when we have to explain to the upper management just how important maintenance is. Trying to translate a maintenance vision into financial benefits is a difficult thing to do, yet we have to if we want to be able to make the right decisions and do the right things to turn it around.

An area that most maintenance mangers seem to struggle with is the business side of their job. It is vital that we begin to understand the financial side in order to sell the organization on your maintenance vision. The biggest key to learning the financial side is that focus needs to be put on the fact that maintenance is a profit center, not a cost center. What needs to be understood, then, is that value, when sold to an organization’s upper management from the maintenance perspective, needs to be defined in terms of dollars. That means every project, plan, or initiative that you want to launch needs to be converted to dollars. Whether it is a raise in your OEE, raise in your wrench time, or prevention of failures, it needs to be captured and converted to dollars.

So let me say it one more time: You have to convert everything you do into dollars. You have to toot your own horn to begin the change of perspective of maintenance being a cost center to being a profit center. What you will find out is that you are probably already doing things that can be captured; you just need to understand how to capture and convert. It is all about perspective. When people hear of all these good things that are going on within your department, people begin to believe.

Business basics

If we really want to gain credibility with upper management (and, to be honest, everyone with whom you come in contact), you have to convert your maintenance initiatives into business language and dollars. For example, you can say that you need a $20,000 investment to start job kitting because job kitting will improve your wrench time. The question is why upper managers would care about job kitting. Do they even know what wrench time is?

Put your request in the right terms. Quantify that an initial investment of $20,000 to establish a job-kitting system will improve your wrench time by X% by eliminating wasted time spent trying to find parts and procedures. Explain that this reduction in waste is expected to lower labor spending by Y amount within Z years. Note that it will also raise productivity because the department will be able to do more with less, likely resulting in a gain in line efficiencies as well. The estimated plant-wide throughput increase thanks to this one initiative will be A%, leading to a profit gain of $B. So, by the end of year Z, your return on investment will be $C or $D.

It is very important that you do this as much as possible with everything that you do but, you first have to learn some basics about business.

Competitive Advantages give a company an edge over its rivals and an ability to generate greater value for the firm and its shareholders. The more sustainable the competitive advantage, the more difficult it is for competitors to neutralize the advantage.

There are two main types of competitive advantages: comparative advantage and differential advantage. Comparative advantage, or cost advantage, is a firm’s ability to produce a good or service at a lower cost than its competitors, which gives the firm the ability to sell its goods or services at a lower price than its competition, or to generate a larger margin on sales. A differential advantage is created when a firm’s products or services differ from its competitors and are seen as better than a competitor’s products by customers.

Understanding your competitive advantage will help you understand your area of focus. If it is a comparative advantage, you will be more cost driven. If it is differential, you will want your equipment to run more efficiently because demand for your unique product will be high. In most industries, the best way to gain market share and increase volume, it is to drive down costs. Driving down costs through reliability efforts will make your organization the most competitive in the market place.

Cash flow

A company’s cash flow is the difference between all the cash that goes out (buying raw materials, utilities, labor, overheads, investment, dividends, interest, and loan payments) and the money that comes in (receipts from customers). If the cash flow is negative, that is, the cash in is less than the cash out, the company will need to borrow more money or it will be unable to buy supplies, labor, utilities, etc. In short, if there is no cash, there is no business.

Under normal economic cycles, businesses will experience a series of upswings and downswings. During the upswing, a business can put on "fat" and then, during the downswing, it is difficult to lose that fat because they are used to operating in a manner consistent with the good times. This fat becomes a burden that exaggerates the effect of the downswing.

The secret to long-term profit maximization is to set up your business with a minimum of fat at all times. This maximizes the profits during a rising market and, when inevitably the market turns, minimizes your harm as business falls.

Where the rubber meets the road

Your goal is to do your part to make sure your organization's cash flow is positive, meaning that the amount of cash in is greater than the cash out. This is a profit gain. Profits do two things: they raise stock value and free up funds for more capital investments.

What can we do to make a positive impact on our cash flow, and turn the thinking around that maintenance is a cost center to a belief that maintenance is a profit center?

1. Work safely. Incidents don’t just hurt people; they hurt business as well. The National Safety Council reported in 2012 that the average comprehensive cost by injury severity was:

- Death: $4,538,000

- Incapacitating injury: $230,000

- Non-incapacitating evident injury: $58,700

- Possible injury: $28,000

- No injury: $2,500

2. Produce high-quality product without mistakes.

3. Produce the lowest-cost product as possible.

4. Reduce storeroom stock and costs incurred because of stockouts.

5. Use condition-based monitoring technologies to cut utility and failure costs.

6. Increase wrench time through planning/scheduling work, eliminating waste and allowing you to accomplish more work in the same amount of time.

Cost savings vs. cost avoidance

Many people do not understand the difference between cost savings and cost avoidance. Cost savings occur when there is a reduction that causes future spending to fall below the level of current spending, whereas cost avoidance refers to reductions that cause future spending to fall but not below the level of current spending.

Consider these scenarios for a better view:

Scenario 1 – Your MRO buyer finds the same part from another vendor at a reduced price, resulting in a savings of $100,000 per year. This scenario reflects cost savings. These cost savings may then be removed from budgets, reinvested, or redirected to other spending priorities, such as process improvements, driving profitability.

Scenario 2 – The buyer also resists a vendor’s attempt to raise prices by 5%, allowing the storeroom to avoid spending an additional $200,000 that year. This second scenario is an example of cost avoidance. Often, cost avoidance involves slowing the rate of cost increases. In other words, future spending would have increased even more in the absence of cost-avoidance measures. Also, and of most importance, prevention of failure will be a cost avoidance.

Your mission: Convert all of these savings to dollars and email the information to relevant parties in your plant to help you change the perception of the maintenance department from cost center to profit center.

Opportunity costs

Opportunity cost refers to the cost of an alternative that is forgone to pursue another action. Let's say the decision is made to run a fan to failure. This decision costs the plant $10,000 in lost production. The cost to do vibration analysis would have been $30 a month. This would have given you the opportunity to plan and schedule work on the fan on a down day, avoiding the lost-production cost. The opportunity cost is $9,970.

KPIs. Which key performance indicators should you track for your political campaign? I measure four things:

- Dollars of maintenance spend to percent of RAV

- Dollars of inventory stock to percent of RAV

- Maintenance cost per unit

- Year-over-year utility spend.

Are these the only KPIs out there? No. These are what I track. Choose to use whichever you see fit. All I am trying to measure is our effectiveness toward profit gain.

Starting your political campaign

Announce that you're starting your campaign, and capture as many cost savings and avoidances as you can. Share your findings with the world. You can even get creative with it. Create a newsletter and share your “Find of the Week,” for example. Here are some other possibilities:

Savings-avoidance log

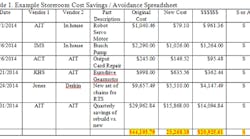

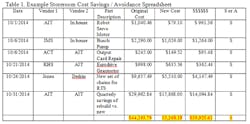

Cost savings is a bit easier to capture than cost avoidance. I give my buyer and planner/scheduler a spreadsheet as shown in Table 1, with a few columns delineating, for example, vendor 1, vendor 2, part description, old cost, new cost, cost savings or cost avoidance, etc. An updated spreadsheet gets turned in to me on a monthly basis, and I share the savings with the leadership group. (In-house vs. third-party rebuilds contribute to cost savings as well.)

Cost avoidances are a bit different. When you talk vendors out of price hikes, that's easy to capture. Make sure your buyer captures these on the spreadsheet, too.

The hard thing to capture is failure prevention. Find out your replacement asset values, your maintenance cost per unit produced, the total cost of downtime with overhead figured in (remember, total cost of downtime per line). Illustrate what a 1% improvement in overall equipment effectiveness (OEE) is worth in profit. Also, find out how long failures normally last. If you use your CMMS/EAM system properly, you should have this information. If you do not, good luck –you will have to do it all manually.

As you begin to sell to members of your organization, remember that return on investment will be key for them. Be sure to capture all you can to show that they are getting this. Brag about your department and learn from your mistakes. Strive to be the best at all you do. In so doing, you'll put yourself in the best position to win the political campaign of selling maintenance as a profit center.

He is a CMRP, CRL, CARO, MLT2, MLA1, LSSGB, IAM-55k, CRL Black Belt and was recognized as one of the top 50 leaders in the country by the United States Congress, being awarded the National Leadership Award.

Most organizations have 3 typical problems: People issues, process issues, or profitability issues. Which is most important to your organization? Which one would you like help with? Please contact [email protected] with any questions or comments.