A U.S. manufacturer of refractory materials recently averted catastrophe by a slim margin. An arc flash began in a switchgear cabinet near the control room, but a just-installed arc flash relay shut off the power before major damage could occur, saving the plant from expensive downtime and equipment replacement costs.

The company operates a plant that makes fiberglass insulating blankets and glass insulating bricks. It is an older facility, and much of its electrical equipment dates to the 1970s. The plant had been having major issues with utility power; there were voltage dips, for which the utility refused to accept responsibility, that caused product quality problems. The refractory company then called on Evans Enterprises to install power quality metering that would detect any anomalies in the incoming power. Evans also did a number of other things around the plant, including installing shunt trips on all the circuit breakers.

An imminent danger

Prior to bringing Evans in, the refractory company had hired an engineering firm to conduct an arc flash analysis in an effort to reduce the arc flash hazard categories of equipment throughout the plant. While this might seem routine, the analysis had uncovered a dangerous situation: One 480 V cabinet, which was fed from a 3,500 kVA transformer, exceeded arc flash hazard Category 4, and there was no level of personal protective equipment (PPE) that would allow a worker to approach the cabinet if it were open. The door to the cabinet was therefore kept closed, and everything related to it was done remotely, but the cabinet, along with the heavy transformer associated with it, is located in a room next to the control room within feet of the operators. This was clearly an untenable situation.

An arc flash is a sudden release of energy caused by a fault between an energized conductor, either to ground or to another phase. It creates intense light that can cause third-degree burns, a high-pressure blast wave, and flying debris.

Protecting against arc flash

A circuit breaker — even a fast-acting one — by itself offers little to no protection against an arc flash, because it cannot operate quickly enough to stop the arc before it reaches dangerous levels. The same is true of a breaker operated by an overcurrent relay. Another issue is that a high-impedance arc fault may not draw enough current to cause a breaker to trip instantaneously, which requires a high-value overcurrent. An arc welder with a 1/8-in. rod, for instance, may use arc current of just 120 A, which is less than the normal trip current of many power-panel breakers. Ground-fault relays and resistance-grounding systems help to protect against arc flash caused by ground faults, but not in the case of a phase-to-phase fault, which is more likely to be caused by electrical worker error and therefore put human life in danger, not to mention the damage to equipment and downtime. One way to protect against all arc flash incidents regardless of the cause is an arc flash relay, which responds to the light of the arc flash itself and shuts off power before the arc grows to a catastrophic level.

How an arc flash relay works

Figure 1. Minimal damage occurred to the bus bar. The whole cabinet would have been destroyed had the arc flash relay not been installed.

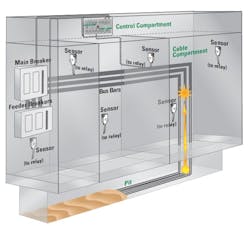

An arc flash relay works by detecting the bright light emitted by an arc and activating the relay trip input to the main circuit breaker upstream, generally in 1 ms, although this time is adjustable in some relays. Most main power breakers will open in 50 ms or less, greatly limiting the damage (Figure 1). The light is detected with a set of sensors, either individual point type or a distributed fiberoptic cable type that is sensitive over its length. Some arc flash relays can also use current transformers on the power inputs to the cabinet or enclosure to be protected. The idea here is to help the relay distinguish between a real arc flash and a sudden bright light that might be caused by nearby welding, flash photography, or even sunlight falling on the open door of the cabinet. If the current transformers are in use, then the arc flash relay looks for a sudden increase in current coinciding with a bright light; if the current is unchanged, then the relay will not trip, helping to prevent nuisance trips. Figure 2 shows a typical connection. In this particular case, current transformers were not needed because the cabinet was in a room by itself with no bright light sources near it.

Figure 2. The electrical cabinet shows arc flash and the arc-flash-relay installation.

When the refractory company asked Evans Enterprises to see what could be done to reduce the arc-flash hazard category, Evans decided to install a PGR-8800 arc flash relay from Littelfuse, which could be retrofitted in the existing panel.

Speed of response is critical; the whole idea of an arc flash relay is that it limits the energy released during an arc flash by “seeing” the light emitted from the flash, interpreting it as a fault, and triggering the upstream breaker to clear the fault in a time that is much faster than a typical overcurrent relay can react. An examination of the specifications for several arc flash relays on the market shows that the fastest possible trip times vary from less than 1 ms to about 9 ms. Trip reliability in the relay can be ensured by redundant trip circuits (both analog and digital) and self-diagnostics, including continuous closed-loop checking of the condition of the sensors.

The cabinet in question contains a three-phase, 4,000 A main breaker that feeds four 800 A MCC feeder breakers, plus one 2,500 A breaker that feeds an SCR power controller that controls current to three electrodes in the glass melting furnace. It has three sections: the back section for the cabling, the middle section for the bus, and the front section where the breakers are mounted. Across the top of the cabinet is another section set aside for control equipment, with no voltage greater than 120 V present. The Evans technicians installed the arc flash relay in this section and mounted two of the relay’s light sensors in each of the other three power compartments. They connected the trip output of the relay to the remote trip input of the main breaker. The installation of the relay was a simple job that took about three hours, including placing the sensors.

After the relay was installed, an engineering firm rerated the cabinet’s arc flash hazard rating from a Hazard Category 4 to a Hazard Category 2, a level approachable using 8 cal/cm2 PPE.

Trial by fire

The timing of this installation was very fortunate. The cabinet sits over a channel in the concrete floor with a dirt bottom. Cables from the load sides of the breakers in the cabinet emerge from the bottom and go down to enter buried conduits that end at the level of the pit bottom. While this would not be permitted in a new installation, this one dated to the 1970s and had been grandfathered.

Over the years, sand from the glass manufacturing process, dirt, and debris had accumulated in the channel, nearly filling it, and had found its way into the open ends of the conduits. The cables coming up through the pit were quite old, and the insulation had become brittle; it was just a matter of time before something happened, and, about a week after the arc flash relay was installed, it did. An arc started on one of the cables a few inches below the surface of the dirt. The arc tracked up the cable to the main bus inside the cabinet, where it became a phase-to-ground arc flash that threatened to destroy the cabinet and potentially the plant, not to mention the effect on any people who might be nearby.

As the flash developed, the relay saw the flash via its sensors and responded by sending a trip signal to the main breaker in less than 1 ms. The breaker then mechanically cleared the fault with a total clearing time of 51 ms. Without the arc flash relay, the breaker would have relied on overcurrent relays, for which a typical trip-signal time is between 16 and 32 ms, adding precious time to the incident energy equation. Instead, damage was minimal: a thumb-sized piece of copper was burnt off one of the bus bars, and the cabinet and the switchgear inside it suffered only minor damage.

The incident energy from the arc flash, which according to the initial arc flash analysis would have been in excess of 40 cal/cm2 without the arc flash, was just 8 cal/cm2, as had been determined by the second arc flash study.

Examination of the cabinet after the incident showed that the relay and sensors were undamaged and that all six sensors had responded to the arc flash. Even sensors that were not in the line of sight reacted to reflected light inside the cabinet. This could be determined both from the LED indicators on the front panel of the arc flash relay, which changed from green to red, and from the self-diagnostic LEDs built into each sensor, which changed from a quick double flash every second to a slow blink to show that they had been activated.

Costs avoided

Suffice it to say that the arc flash relay did its job and saved the company a great deal of expense and downtime. Had the relay not been there, the refractory company could have had costs of up to $1 million. A switchgear cabinet with a 4,000 A main breaker and one 2,500 A and four 800 A load breakers, plus the necessary bus bars, insulators, and cables are not off-the shelf items, and would have cost $100,000. And getting it into place would have required cutting a hole in the side wall of the plant. But that would have been only a small fraction of the cost, considering downtime. The lead time on electrical equipment of that size would be anywhere from 10 to 24 weeks, and that’s just for delivery, not installation. Those 24 weeks of downtime represents 46% of a year’s production.

| Tim Deschamp is power switch division manager at Evans Enterprises. Contact him at [email protected]. |

As it turned out, the repairs to the switchgear consisted of replacing a few insulators at a cost of about $6,000, and that was because the 1970s-vintage equipment could not be purchased from the manufacturer. Fortunately, Evans Enterprises was able to obtain the necessary parts from cabinets we had in stock, and the plant was back up and running within 24 hours.

Summary

This is an example of how a dangerous situation was made much less so by the installation of one piece of safety equipment. The fact that the incident described occurred just a few days after the arc flash relay was installed shows that it is never too early to adopt proper safety practices.