In brief:

- A primary consideration when selecting a seal is whether the seal is a pusher or non-pusher type.

- Another consideration is the amount of tension the spring applies to the seal faces.

- The other important component of the seal is the stationary face ring, which often mounts in a recessed bore at the bottom of the seal chamber.

With the variety of seal types, materials, and pump designs, it’s inevitable that what works well for one mechanical seal installation may not work for others. Some practical considerations might help to determine the best techniques for the pumps that might be encountered.

Non-pusher and pusher type seals

A primary consideration is whether the seal is a pusher or non-pusher type. The difference is not always obvious. The seal head of a pusher seal must move freely on the shaft during operation. If it sticks to the shaft, the spring cannot apply proper tension to the seal faces, so the seal will leak. Non-pusher seals, however, should actually grip the shaft during operation.

Non-pusher seals will have provisions for the spring to move the seal face independently of the elastomer that seals it to the shaft. That elastomer, generally called the secondary seal, can be an o-ring, a boot, a wedge or other shape or construction.

So how can you tell if a seal is a pusher or non-pusher type? Reach inside the bore of the seal head and hold the head at the secondary seal. Now push on the seal face assembly and see if it will move slightly toward the secondary seal. A non-pusher seal will move an eighth of an inch (3 mm) or so; a pusher seal will not. John Crane types 1, 2 and 21 and U.S. seal manufacturer types A through Q and S, T and U are all non-pusher seals (Figure 1).

Figure 1. When you push on the seal face assembly, a non-pusher seal will move slightly toward the secondary seal.

Seal installation

For pusher seals, the shaft should be polished to a 32-16 rms finish, which has a glassy appearance. The shaft for non-pusher seals should have a 90-62 rms finish, which looks slightly duller. No machining marks, threading or scratches of any kind should be present in either case. Both kinds of seals must also slide into the proper location on the shaft during installation without “rolling,” cutting, or otherwise damaging the elastomer device (secondary seal) that seals it to the shaft.

[pullquote]Some seal manufacturers recommend applying a glycerin-based, water-soluble lubricant to the shaft to allow the seal to slide smoothly into place. Others suggest coating the shaft with a light machine oil. Some pump manufacturers recommend a light grease for this purpose. The key is to use a lubricant that is compatible with both the elastomer material and the application (the pumpage). For instance, Nitrile (Buna-N) is not compatible with brake fluid. Motor oil may not be something customers want in their process fluids. Silicone lubricants such as WD-40 will not allow non-pusher seals to grip the shaft after installation. The glycerin-based lubricants seem to be satisfactory for most installations.

If the seal head must slide over a keyway or shaft shoulder during installation, the elastomer secondary seal may be damaged. Wrapping that section of shaft with a small piece of Mylar or stiff insulation paper will prevent such damage.

Amount of spring tension

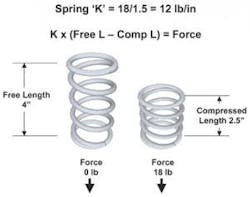

Another consideration is the amount of tension the spring applies to the seal faces. This is a factor of the amount the spring is compressed (Figure 2). Most seal suppliers and pump manufacturers provide a working length for the seal that determines the amount of spring tension. Switching seal suppliers can mean different working lengths. The pump manufacturer may specify a certain length, but a third-party seal supplier may have a different design, and a different working length.

Figure 2. Most seal suppliers and pump manufacturers provide a working length for the seal that determines the amount of spring tension.

Any machine work that may have been done to the shaft, bearing housing, or seal housing has the potential to alter the working length of the seal. On occasion, it may be advantageous for a user to swap parts from various new or used mechanical seals. In such cases, it is important to calculate the correct face tension and appropriate seal working length. While springs from different seals may appear similar, their spring constant (K) may be quite different.

Seal faces are lapped to precision smooth and flat specifications, usually to 3 helium light bands. The faces must be kept absolutely clean and scratch-free. Many suppliers caution against using any type of lubricant on the seal faces. However, at least one pump manufacturer has seal installation instructions that tell you to oil the seal faces. Some seal suppliers recommend that a glycerin-based lubricant should be applied to the seal faces.

Seal faces can always be lubricated with either a pure quantity of the fluid that is being pumped (pumpage) or with the barrier fluid used in the seal cavity for dual seals. Most submersible pumps use oil as the barrier fluid.

Work in a clean environment

One issue with applying a lubricant to the seal face is that lubricants trap airborne contamination, which can damage the seal face when the pump is started. Working in a clean environment and minimizing the time that seal faces are exposed will alleviate this risk. Incidentally, some may ask: “Where do you find a clean environment in a maintenance area?” The answer is that you must create one; a clean environment for pump assembly is an important element in quality pump repair.

Stationary face ring

Figure 3. Some seal suppliers caution against even touching the seal face, since that may leave fingerprints that can trap contamination and damage the face.

The other important component of the seal is the stationary face ring, which often mounts in a recessed bore at the bottom of the seal chamber. That can make the stationary face ring difficult to install if the seal chamber is small enough to limit access. Even when the mounting location is accessible, applying the necessary force to seat the face ring properly can be a challenge. As with the secondary seal on the rotating head of the seal, the stationary face ring will be mounted in an elastomer cup or boot, or with an o-ring. Therefore the same concerns for using a lubricant exist.

It is often necessary to press directly on the seal face to seat the stationary face ring (Figure 3). But some seal suppliers caution against even touching the seal face, since that may leave fingerprints that can trap contamination and damage the face. The solution is to wear clean latex gloves when handling the seal and touching the seal face or to use a piece of the wrapping paper from the seal package to protect the seal face when pressing it into the bore. Special installation tools that are available for some seals may be simply a section of plastic tube that fits the outer edge of the seal face. Sometimes a suitable installation tool can be fashioned from a clean piece of PVC pipe. Such tools should not touch any part of the seal face that will contact the rotating face.

| Eugene Vogel is a pump and vibration specialist at the Electrical Apparatus Service Association (EASA, www.easa.com) in St. Louis. Contact him at (314) 993-2220. |

It is absolutely critical that the installed stationary seal face be square to the shaft rotating axis. The seal ring mounting bore should have been checked for squareness during the repair process. The elastomer cup, boot, or o-ring must be in excellent condition, free of any anomalies that would prevent the face ring from seating properly. The edge of the mounting bore should have a slight chamfer to allow the face ring to be pressed in smoothly and fully against the bottom of the bore.

Given the wide range of seal and pump types and applications, there is no single best way of installing a mechanical seal. Although seal suppliers and pump manufacturers often can provide installation instructions and recommendations for specific applications, the tips outlined here can help users deal with common issues that occur during mechanical seal installation.