Expert advice on rotary PD pumps

In brief:

- The rotary positive displacement pump can outperform a centrifugal or vertical pump under certain operating conditions.

- The positive displacement pump can self-prime if the differential between the net positive inlet pressure available exceeds the net positive inlet pressure required.

- A consolidated range chart and a capability table are two important tools for selecting an efficient pump.

This is the third in a series of articles based on Hydraulic Institute’s comprehensive e-learning course, “Positive Displacement Pumps: Fundamentals, Design and Applications.”

Last month, we focused on positive displacement pump hydraulics. In this installment, we’ll focus on an overview of the common characteristics of rotary pumps, the pump types within the pump family and the application analysis and pump selection processes.

Rotary pumps are available to handle a broad range of flows and pressures, which explains why users recognize them as the solution for many pumping needs. Recent enhancements have increased rotary pump reliability and operating envelopes. They’re increasingly recognized for efficiency in an energy-conscious environment.

A rotary pump typically has a stationary pumping cavity containing rotating pumping elements powered by a drive shaft. This rotary motion is the distinguishing feature of this class of pumps, hence, the name rotary pump. The pumping elements are characterized by close-fitting running clearances. Rotary pumps have no need for separate inlet or outlet valves.

The rotating pump elements draw fluid through the suction port into the pumping cavity, transport it through the pumping elements and force it through the discharge port into the system. Pump element and pumping cavity geometry determine the volume of fluid pumped per shaft revolution. This volume is called the displacement. Most rotary pump types are configured for fixed displacement; however, they can produce variable flow rates by varying the shaft speed. Vane and piston rotary pumps produce variable volume by changing the internal geometry, that is, by varying the displacement of the pumping elements.

Rotary pump types

The most common types of rotary pumps and their subcategories are shown in the rotary pump tree (Figure 1).

Figure 1. The many varieties of rotary positive displacement pumps can be configured to handle a range of applications.

Vane-in-rotor pumps have movable vanes, or rigid blades, that are retained, but not necessarily fixed, by an eccentric rotor that turns within the pumping cavity. This action draws fluid in and forces fluid out of the chamber, thereby delivering flow. Vane pumps can have fixed or variable displacement.

The Hydraulic Institute is the largest association of pump producers and suppliers in North America and is a global authority on pumps and pumping systems. Its mission is to serve as a forum for the exchange of industry information, while providing value-added services to member companies and pump users worldwide. Nearly 100 companies belong to HI, and engineering consulting firms affiliate as “Standards Partners.” For more information about the Hydraulic Institute, its member companies and Standards Partners visit www.pumps.org.

Along with e-learning courses, HI also offers ANSI/HI Web-based standards subscription packages. Web-based subscriptions provide company-wide access to the ANSI/HI Pump Standards for one or more simultaneous users, 24 hours a day, 7 days a week, from anywhere in the world. You might access your ideal subscription from the Web or download to view locally. Visit estore.pumps.org/subscriptions to learn more.

Attend any “Pumping System Optimization” course and receive seven PDH credit directly from HI. Those interested in hosting the course might do so at their own facilities. For more information about attending or hosting a course in 2011, visit www.pumpsystemsmatter.org or call Kathy Doran at (973) 267-9700, ext. 216.

Rotary piston pumps produce flow as fluid is drawn in and forced out by multiple pistons that reciprocate within cylinders in a cylinder block. The two types are axial and radial piston. Both are available as fixed and variable displacement pumps.

Flexible-member pumps transfer product from the inlet to outlet by making use of the elasticity of the flexible members. The flexible members might be a tube, vanes or a liner.

Lobe pumps carry the pumped fluid from the inlet to the outlet between rotor lobe surfaces and the pumping chamber. In this regard, they’re similar to gear pumps but don’t produce the shear effects. Timing gears coordinate the motion of the lobe surfaces, avoid surface contact and provide continuous sealing.

Gear pumps carry the pumped fluid between gear teeth and displace it as the gears mesh. The gear surfaces cooperate to provide continuous sealing, trap pockets of the pumped fluid and push it out the discharge port. One gear drives the idler or driven gear. There are two main variations — external and internal gear pumps.

Circumferential piston pumps have timed rotors and each rotor has one or more wing lobe elements, called pistons. There’s no sealing contact between the piston surfaces.

Single-screw pumps, commonly called progressing cavity pumps, have a rotor with external threads and a stator with internal threads. The geometry of the rotor and stator are such that cavities form and progress from inlet to outlet as the rotor spins to produce the pumping action.

Multiple-screw pumps are divided into two broad families — timed and untimed. Typically, multiple-screw pumps have two or more intermeshing screws and the flow is in the axial direction. The inlet fluid, which surrounds the rotors, is trapped as the screws rotate. With the rotors in tight-fitting bores and the casing acting as the stator, rotor action moves the fluid uniformly along the axis and forces it out at the other end.

Application analysis

The application analysis stage is a vital step in the selection process. Application of rotary pumps benefits from careful attention to the system’s performance requirements. Application analysis determines initial affordability, flexibility to cover the application’s entire operating range, reliability and energy requirements. It’s important that you understand, identify and communicate your requirements to your pump supplier. The recommended analysis sequence is (a) consider the characteristics of the fluids to be pumped, (b) consider the operating conditions the process requires and (c) determine the system’s hydraulic requirements (Figure 2).

Figure 2. These are the elements of the three-step process for identifying a suitable rotary positive displacement pump.

The ability to self-prime is an important advantage that rotary pumps have over rotodynamic (centrifugal and vertical) pumps. But the design of the pumping elements and the inlet configuration introduce considerable variation in suction capability among rotary pumps. It’s important to remember that the fluid to be pumped is pushed into a pump by the differential pressure available at the pump inlet. Therefore, special attention should be focused on inlet conditions. Users and system designers are advised to ensure the system’s net positive inlet pressure available (NPIPA) exceeds the pump’s net positive inlet pressure required (NPIPR) by a reasonable margin.

Because a rotary pump delivers an essentially constant volume of fluid per shaft revolution regardless of system pressure, it’s necessary, when applying rotary pumps, to provide protection against over-pressurization in the event of a system malfunction.

Pump selection

The third module of the PD pump course explores the various types of positive displacement rotary pumps. Topics covered include:

- Definition of the types of rotary pumps

- Selection, sizing and performance considerations common to rotary positive displacement pumps

- Basic pumping concepts, operating features, benefits and typical applications of the different types of rotary pumps.

The module includes a section covering each rotary pump type. A quiz and an interactive component-labeling activity at the end of each section help to reinforce subject matter comprehension.

The flow a rotary pump delivers depends on its displacement per revolution, operating speed and slip flow. Even though rotary pumps have close internal clearances, there will be some leakage between high-pressure outlet and low-pressure inlet volumes within the pump. This leakage is called slip and might be large or small depending on the type of pump, fluid characteristics and operating conditions.

Rotary pump input (brake) horsepower requirements vary as a function of the pump type and the application’s operating conditions. Input power is the sum of the power required to move the pump’s theoretical flow volume against differential pressure plus internal power losses. Internal power losses include mechanical friction and the viscous drag and shearing effects of the pumped fluid.

Many rotary pump types are available, which makes the selection of the proper unit for the application seem complex. The selection process involves matching the pump’s capabilities with the fluid properties, operating conditions and system requirements identified in an application analysis. Rotary pump performance capability must be verified over the full range of the required operating conditions. Two useful tools help narrow the choice.

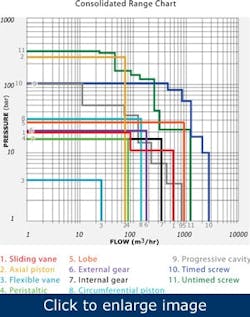

A consolidated range chart (Figure 3) depicts the flow and pressure envelopes of each rotary pump type. Given knowledge of the full range of application flow and pressure requirements, use the range chart to identify suitable rotary pump types. Consultation with the supplier is recommended to confirm specific application recommendations and to investigate special designs, which often are available to provide unique solutions.

Figure 3. The consolidated range chart maps the pump type to the process requirements.

A capability table (Figure 4) provides an overview of operating ranges and application characteristics for the rotary pump types. The table shows relative capabilities such as abrasive handling, shear sensitivity and pulsation, which are dependent on application conditions and the pump technology to which the comparison is made. Shear sensitivity relates to the effect the pump has on the pumped fluid. The abrasive handling capability ratings allow inclusion of material enhancements. The appropriate rotary pump for each application can be identified by matching capabilities to requirements.

Figure 4. The table applies solid values to the variables involved in selecting a rotary positive displacement pump.

Energy efficiency and power savings

Rotary pumps are known for their ability to pump viscous fluids more efficiently. Figure 5 uses HI/Europump Life Cycle Cost Guideline data and compares maximum attainable rotary efficiencies to maximum attainable rotodynamic efficiencies. Specific attractiveness can be identified for applications with viscosities as low as 10 centiStokes (cSt), or 60 Saybolt universal seconds (SSU), and differential pressures greater than 50 psi. Note that the chart is based on operating a centrifugal pump at its best efficiency point (BEP). If the pump is installed in a system in which pressures vary, the centrifugal pump operating point typically moves along the operating curve to the intersection with the system curve, which is typically a lower efficiency region.

Figure 5. This chart shows the approximate pumping efficiencies for several types of rotary positive displacement pumps.

Having a working knowledge of rotary pump fundamentals and the specific process application and system for which the pump is being selected is essential for making a good pumping choice. Basic differences in operating capability can guide rotary pump type selection. Selecting the pump to match system and operational requirements is key to reliable operation and low ownership cost.