Fundamentals of positive displacement pumps

In brief

- PD pumps handle flow rates from less than 1 gpm to 15,000 gpm and pressures from a few psi to more than 70,000 psi.

- Be aware of the reasons that positive-displacement pumps might be the best solution to a specific pumping problem.

- Positive displacement pumps perform across a range of process conditions, including viscosities to 3 million SSU, flow rates from less than 1 gpm to 15,000 gpm, and pressures from a few psi to more than 70,000 psi.

- The 12 reasons to select PD pumps are grouped by fluid characteristics, pressure conditions, environmental system requirements and flow control.

Positive displacement pumps are used in myriad applications across multiple industries. Users have found them to be the solution to many specific pumping challenges. However, because of their size, simplicity and ruggedness, they often aren’t as well understood as other pump types.

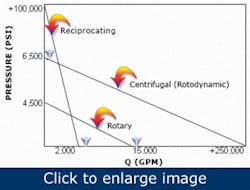

Technologies within the extensive positive displacement family enable coverage of a broad range of horsepower, fluid and pressure applications (Figure 1). These products, therefore, merit increased consideration in the pump selection process. To help in the understanding of the definitions, applications, installation, operation, maintenance and testing procedures, the Hydraulic Institute published 10 ANSI/HI Standards covering air-operated, controlled-volume-metering, reciprocating and rotary PD pumps.

Figure 1. There are many types of positive displacement pumps that can find application in the plant.

Centrifugal versus PD pumps

ANSI/HI standards perform a vital function in pump-industry commerce and serve important roles in minimizing misunderstandings in the marketplace. The Hydraulic Institute, in responding to member and pump-user needs, has extended its mission to include the development of a pump-knowledge and education portfolio. Among the first key elements is a relaunch of the centrifugal-pump e-learning course and the development of a new positive-displacement-pump course covering fundamentals, design and applications. These and future courses will be hosted within HI’s new educational portal, www.pumplearning.org.

The PD pump e-learning course is a five-module, Web-based learning program designed to provide a broad and comprehensive knowledge of positive displacement pumping technologies. Material is highly visual and interactive and is designed to allow the student to take full advantage of the latest Web technology.

Content is arranged in independent modules, each of which focuses on markets and applications, and provides basic recommended technical terms and fundamentals for an understanding of positive displacement pump hydraulics. The first two modules in the series are titled “Why Positive Displacement Pumps?” and “Positive Displacement Pump Hydraulics.”

Three additional modules are each devoted to a specific positive-displacement pump technology. To enhance the learning experience, these modules rely heavily on color photographs of pumps and pumping installations.

The rotary pump module addresses vane, rotary piston, flexible member, lobe, gear, circumferential, piston, progressing cavity, timed screw and untimed screw pumps. The reciprocating pump module covers power, direct acting, power diaphragm, air-operated double diaphragm and air-operated piston pumps. The module on metering pumps focuses on a review of torque sources, drive mechanisms, capacity control and the liquid end.

Modules are designed for either self-instruction, instructor-led courses by one of the 12 PD pump company sponsors, or as HI-sponsored webinars. Each module, designed to stand alone or combined with others, includes an examination and completion certificates suitable for submitting for professional development hours or continuing education credit. Additional detail about these courses is available at www.pumplearning.org. Hydraulic Institute PD pump sponsors have exclusive access to the course for group training within their organizations. Educational institutions and professional societies should contact HI for special PD e-Learning program opportunities.

Pump education courses typically highlight rotodynamic (centrifugal and vertical) pumps, and a good knowledge of that technology is helpful for understanding positive-displacement pumps. Many subjects are common, but certain terms and concepts are unique because PD pumps involve an entirely different technology.

In simple terms, the impeller in a centrifugal pump moves a stream of liquid from the pump suction to a discharge cone, where the gradually decreasing kinetic is converted to pressure energy. A positive-displacement pump, however, doesn’t rely on a velocity change. Pressure is obtained as liquid and is forced through the pump discharge into the system, thereby converting shaft work into pressure. An example of this principle is reciprocating motion, in which a moving piston forces liquid out of a closed cylinder through inlet and outlet valves.

Reciprocating pumps represent one form of PD technology. In portions of their operating range, reciprocating pumps are the single technology that can successfully provide the necessary pumping solution.

Rotary pumps constitute the second major positive-displacement category. In this case, a rotating pumping element inside a pumping chamber drives the fluid. This family is distinguished by its lack of inlet or discharge valves. These pumps are available in a number of pumping principles, each with its own features and benefits that provide specific pumping solutions.

The third major category is the controlled-volume metering pump (CVMP). These often are called chemical-injection feed pumps or dosing pumps. Essentially, these are reciprocating positive-displacement pumps configured to dispense an accurate volume of liquid during a specified time period using any of several mechanisms for varying the effective volumetric displacement. This pump type is used where highly accurate, repeatable, adjustable flow rates are required.

Pumping solution products

Positive displacement pumps often are called “pumping solution products,” because they perform that function for applications across a range of process conditions. For example, rotary PD pumps handle viscous products (3 million SSU), whereas reciprocating pumps handle water-thin liquids. PD pumps handle flow rates from less than 1 gpm to 15,000 gpm and pressures from a few psi to more than 70,000 psi. It’s important to emphasize that PD pumps, at constant speed, are constant-flow devices, whereas centrifugal pumps are variable-flow devices. And PD system design requirements are very different from those for centrifugal pumps. For example, PD pumps require some type of pressure protection, and certain designs require pulsation control.

PD pumps can be used almost anywhere, but the generally accepted view is that more than nine out of 10 PD applications are in six industrial markets:

- oil and gas

- water and wastewater treatment

- chemical

- food, beverage and pharmaceutical

- power

- general industrial (marine/medical/OEM).

Many of these industries are representative of multiple markets. Oil and gas, as an example, has distinctly different applications for PD pumps across its segments: exploration, production, pipeline, processing and distribution marketing. The food and beverage market is another key positive-displacement market with multiple segments that include beverage, bakery, confectionary, dairy and meat packaging.

A dozen benefits

Some applications clearly should use positive-displacement pumps and others should use centrifugal pumps. It’s important to recognize, however, the broad range of applications in which both types should be considered with selection being based on the user’s desired results. Be aware of the reasons that positive-displacement pumps might be the best solution to a specific pumping problem. Twelve reasons to select PD pumps, grouped by fluid characteristics, pressure conditions, environmental system requirements and flow control are summarized below. Table 1 provides a matrix of the 12 reasons compared to the primary markets of PD pumps.

Table 1. These are the pump-application characteristics that prompt specific industries to select positive-displacement pumps.

High viscosity

Certain rotary technologies and air-operated piston pumps easily handle viscous fluids, whereas frictional losses degrade centrifugal pump flow rate and efficiency when used with fluids that have a viscosity above 500 SSU. Flow and efficiency in a rotary pump, however, typically increase with viscosity. In fact, PD pumps can handle fluids with viscosities of several million SSU.

Low and variable viscosity

PD pumps, such as vane or air-operated double-diaphragm (AODD), often are used for thin fluids. Other liquids, such as oil, have viscosities that vary with temperature. With variable viscosity liquids, a moderately small change in viscosity can have a large effect on centrifugal pump efficiency but little effect on PD pump efficiency.

Low-shear pumping

In many fluid applications, liquid shear isn’t a problem; however, in some applications it is critical. PD pumps excel in the handling of shear-sensitive fluids.

Solids-handling capability

[pullquote]Progressing-cavity pumps handling the high-solids-content sludge in a waste treatment plant and coal slurry pipelines use reciprocating pumps to handle fluids with a solids content as high as 40% by weight. You might find this to be a surprising PD pump characteristic, but widely varied applications serve as examples.

Multi-phase flow

A centrifugal pump needs a constant source of liquid, but not all processes can provide it. If there’s insufficient liquid at the pump suction, a gas bubble forms, the pump loses its prime and the fluid stops moving. Such isn’t the case for PD pumps because they’re capable of handling a high percentage of air or gas entrainment.

High pressure

Beyond the range of centrifugal pumps are many chemical, sandblasting and high-pressure water-cutting applications in which PD pump technology dominates. Figure 2 provides an overview of the pressure and capabilities among pump technologies.

Figure 2. This chart shows the regions where the three pump technologies can function at their best.

Low flow

PD pump technology easily handles flows below 100 gpm and pressures greater than 200 psi.

Efficiency

HI is the largest association of pump producers and suppliers in North America and is a global authority on pumps and pumping systems. Its mission is to serve as a forum for the exchange of industry information, while providing value-added services to member companies and pump users worldwide. Nearly 100 companies belong to HI, and engineering consulting firms affiliate as “standards partners.” For more information about the Hydraulic Institute, its member companies and standards partners visit www.pumps.org.

The Hydraulic Institute Positive Displacement Pumps: Fundamentals, Design and Applications five-module course can be found at www.pumplearning.org, an educational website created by HI to serve pump-users worldwide. The website also offers other e-learning and in-person courses and technical webinars. PDH credits, awarded by HI, are provided upon completion of any e-learning course, in-person or technical webinar offered by HI or its Pump Systems Matter (PSM) organization.

The first module of the Positive Displacement Pumps and companion Centrifugal Pump course is available free of charge on the HI website at www.pumps.org/freestuff. The “free stuff” page also includes other useful information to pump users, including executive summaries of HI/PSM guidebooks, an index to ANSI/HI Pump Standards and access to free software tools to evaluate pumping systems.

The Fundamentals of Positive Displacement Pumps course was created by the following positive displacement pump companies, and their subject matter experts, who are members of the Hydraulic Institute:

- ARO/Ingersoll Rand

- CLYDEUNION

- Flowserve Pump

- Grundfos

- Iwaki America

- Leistritz

- Milton Roy

- Moyno

- Warren/Colfax

Among the pump user community HI is known for world-class standards that define pump nomenclature, definitions, application, operation and test procedures. Over 80% of pump tests performed are conducted based on standards created by the Institute.

HI and PSM webinars address such topics as “Pump Systems Energy Assessments,” “Variable Speed Pumping,” “Fundamentals of Mechanical Seals” and “HI’s New Pump Test Standard.”

For viscous fluids that both PD and centrifugal pumps can handle, the positive-displacement option often can be 10 points to 40 points more energy-efficient than the centrifugal pump.

High-pressure, low-flow, efficiency demand

Any of the previous three individual characteristics are reason enough to use PD pumps. But, if the application features all three simultaneously, the PD pump solution becomes the obvious choice.

Sealless pumping

Magnetic drives and canned motor pumps, which require no shaft seals, are available in PD pump designs. Other designs that have no shaft penetration include peristaltic and diaphragm pumps.

Self-priming

The PD pump’s ability to self-prime is a useful feature because it allows substantial flexibility in system layout and eliminates the need for suction-priming systems. PD pumps aren’t only self-priming; they also have excellent suction lift capabilities — raising liquids on the suction side — and are capable of drawing down to near vacuum.

Constant flow/variable pressure

At a constant speed, PD pumps deliver practically constant flow. This is true even if the system pressure varies, which is a desirable condition in certain systems.

Accurate, repeatable measurement

Because a PD pump is a constant-flow device, certain designs that limit slip are useful for metering fluids into or out of systems. This application, of course, requires accuracy and repeatability. It might also need flow variation, which typically is obtained mechanically or electronically by speed variation.

There’s a universe of standard PD solutions in addition to the baker’s dozen described here. Because these pumps also must meet many other requirements, manufacturers provide products with special options, such as jacketing, non-corrosive materials and built-in pressure relief valves, to name a few. Some PD units have duty-cycle limits that users should investigate. It’s important to note PD pumps are constant-torque devices. In variable-speed applications, VFDs must be rated with that understanding.