With their unparalleled lifespan, energy-efficiency benefits and modern aesthetic appeal, it’s no wonder light-emitting diode (LED) illumination has soared in popularity during the past few years. The technology is no longer reserved for mainstream architectural applications, outdoor signs and signaling devices. Breakthroughs in semiconductor technology have broken the barriers for efficiency and brightness that prevented widespread use of LEDs in general illumination, now making it possible to use LED lighting in the industrial environment.

High-performance solution

|

View more content on PlantServices.com |

A well-designed and carefully planned LED system can be a practical, high-performance solution for a variety of industrial lighting applications, including flood lighting, wide area lighting and task lighting. For industrial facilities, lighting system selection should be carefully weighed because these facilities generally have much more complex requirements related to safety and productivity. As with any product selection, it’s important to evaluate the benefits, costs and most appropriate options to make the most-educated decision.

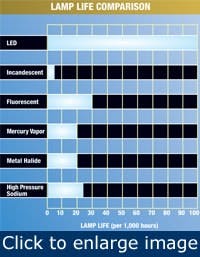

Figure 1. This chart compares the expected life of various lamp types, which translates into expected maintenance costs.

Perhaps the greatest benefit of LED lighting is its extremely long lifespan. LEDs rarely fail or burn out, instead they dim slowly over time while providing continuous useful life. The service life of an LED is typically in excess of 50,000 hours, and in some instances as many as 100,000 hours. This reduces lamp replacement and labor costs while additionally deferring maintenance requirements (Figure 1).

Unlike fluorescent and HID light sources that use mercury to generate light, LED lighting uses no mercury, eliminating the disposal of hazardous substances. And because LEDs save energy, they reduce the overall effect of fossil fuels on the environment.

Because products specified for industrial applications must meet harsh demands and often are installed in areas subject to high vibration levels, LEDs serve as a highly-functioning choice because they contain no fragile filaments or glass. LEDs also start instantly, requiring no warm-up period to reach full brightness. This is in contrast to HID-based lighting systems that require several minutes to start, as well as to re-strike in the event of a power loss. Also, linear fluorescent and compact fluorescent lighting systems exhibit limited performance and starting difficulties at colder temperatures. In contrast, LEDs are designed to operate even in extremely low temperatures with no loss of lumens. In many industrial applications, instant-on and low-temperature operation are critical requirements.

Recent improvements provide benefits that weren’t available with the original LED technology. Besides instant on and off, LEDs offer dimming, color temperature control and fault detection. LED systems also can be designed so that a fixture can stay illuminated, even if one or more LED components fail.

Reduced lifecycle costs

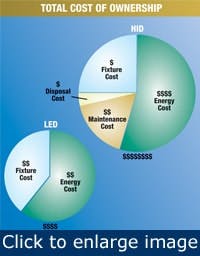

Figure 2. Lighting is no exception to the wisdom of considering the lifetime cost of any asset you purchase.

While it’s true that LED lighting systems require a greater initial investment than some alternative lighting systems, LEDs can be a much more cost-effective option when you consider life-cycle costs. LED systems can reduce energy consumption, improve light levels and reduce maintenance costs. This means that, over time, LED lighting can be a less expensive, more reliable option that reduces costly maintenance requirements (Figure 2).

LED-based systems generally consist of an LED package and module, thermal management solution, optics, a control circuit, and a power supply or driver. While many LED packages feature these components, they’re not all designed for industrial lighting applications that have high performance demands. Therefore, you’ll need to take additional factors into consideration when evaluating an LED system for an industrial facility.

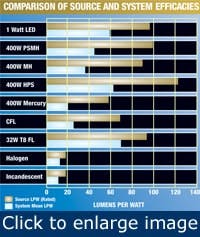

You’ll need to assess the complete system, including lumen output, lumen depreciation, efficiency and color quality. Well designed products with good optical efficiency and thermal management will be able to deliver more lumens, on average, than traditional lighting technologies such as HID, fluorescent, incandescent and halogen (Figure 3).

{pb}Figure 3. LED technology is more economical than at least seven competing technologies.

Thermal management of an LED system is the single most challenging — and crucial — task for an LED system designer. Although LEDs can feel cool to the touch, the life of the LED and lumen performance is directly related to its internal temperature. Industrial applications often expose a light fixture to elevated temperatures. An increase in ambient temperature will have a direct effect on the LED junction temperature. This is why it’s important to consider application requirements to meet the challenges associated with maintaining the LED performance over its life.

Another factor affecting LED operation and lifecycle is the operating current. Overdriving the LED system by increasing the current increases light output, but often will result in a greater junction temperature. A successful product installation must consider the application and optimize the design to maximize the LED performance and life requirements. When evaluating an LED system, consider both fixture construction and intended performance in line with the specific application.

It’s also important to note whether the application involves wide-area lighting, task lighting or both. For task lighting applications, where the goal is to illuminate equipment, LEDs can effectively illuminate tanks, instrument panels, switch racks, storage areas, pathways and security areas.

Retrofits require careful considerations

For new construction, lighting considerations are generally straightforward. Older facilities require comprehensive system evaluation to carefully measure existing lighting systems to confirm actual light levels before designing an LED system.

[pullquote]For example, a 25-year-old chlorine processing facility was still using 175-W mercury vapor lamps in Class I, Div. 2-rated light fixtures. The lamps burned out frequently, and relamping was both difficult and time-consuming because many of the fixtures were located over large tanks and equipment. Light levels were insufficient. After a thorough evaluation, the choice was LED lighting that could deliver optical efficiencies in excess of 80%, more lumens to targeted areas and a 60,000-hour life cycle.

After the switch to LED lighting, the facility experienced a 50% reduction in energy usage, an average light level improvement of 25% and reduced maintenance costs.

Choosing an LED manufacturer

From LED design engineering and challenges to component integration and thermal management, the range of elements that go into evaluating an LED system properly make it crucial to partner with a knowledgeable manufacturer. It’s important to note that not all LED systems and manufacturers are equal. Beware the non-lighting manufacturers getting into the LED market without competent knowledge of general illumination or the LED industry as a whole. Industrial facilities seeking to implement an LED system should partner with a company that maintains a proven track record and offers products complying with standards determined by independent lab tests, including Underwriters Laboratories (UL) and Canadian Standards Association (CSA) requirements.

Choose a manufacturer that offers a lighting layout analysis to develop a model of your existing lighting system and confirm actual light levels. This will provide added accuracy when it comes to evaluating and selecting a new system, especially for retrofit installations. Many manufacturers also offer tools to help calculate LED performance variables, which can help determine the return on investment.

Recent advances in LED technology are providing customers with a better choice of lighting options that take into consideration energy efficiency, safety, maintenance and productivity.

Michael Neary is a product line manager for Cooper Crouse-Hinds in Syracuse, N.Y. Contact him at [email protected] and (315) 477-5607.