Coal to maintain leading role in electricity production

Looking back over the last 150 years or so, it is not hard to see that electricity has been a primary force in shaping human development. It has been a basic ingredient in our industrial revolutions that simultaneously improved the productivity, working and living conditions within our farms, factories, hospitals, offices and homes.

Today, it has become an essential part of our daily life and our future. Our economies need it to grow, our scientists need it to discover, our doctors need it for our health care and our nations need it for our security and defense. The amazing thing is that we keep finding new ways to use electricity to make our lives more safe, comfortable and productive. It is a great success story of human ingenuity, achievement and development.

Our hunger for electricity

The convenience and value of electricity has not gone unnoticed by consumers. According to the Department of Energy1 (DOE), electricity is the fastest-growing form of energy in the world, and during the next 20 years, the world will likely consume twice as much of it as it does today.

In 2008, we consumed almost 20,000 terawatt hours of electricity globally1. That’s enough electricity to light-up over two million baseball stadiums or power over 11 billion computers continuously for an entire year. No matter how you look at it, we consume an incredible amount of electricity.

The United States has the dubious distinction of being the largest consumer of electricity in the world with enough power to provide each American with over three kilowatts of electricity — that is about twice the power currently available to Europeans, eight times the power available to the Chinese and over 25 times the power available to the citizens of India2.

Yet the US represents less than 5% of the world’s population. Further, an astounding 1.6 billon people (almost 25% of the world’s population), doesn’t have access to electricity at all1.

The rest of the world has a long way to go to catch up with the US and if they ever do, we would need over five times more power plants than we currently have in the world today.

Electricity and the environment

Electricity is not an energy source by itself; rather it is produced from primary energy sources like fossil fuels, nuclear and renewable energy. Today most of our electricity, about 67%, is produced from fossil fuels (coal, natural gas and oil), with coal being the largest single contributor producing about 43% of the total electricity in the world1.

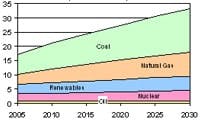

(Click to enlarge image) Figure 1 — World electricity generation (terrawat-hours)

Looking out to the future, to feed our tremendous hunger for electricity, we will need to tap deeper into all of our world’s primary energy sources. Most projections show that coal will maintain its leading role in producing the world’s electricity.

There are good reasons for coal playing such a large role in our power generation. It is the most abundant primary energy source in the world, capable of supporting our energy needs for over 300 years at our current usage rate, as compared to oil or natural gas which is projected to be exhausted in about 30-50 years3. It is located in or near our largest population centers and our largest industrialized countries like the US, UK, Germany, China and India. It can also be easily transported and produces among the most reliable and affordable electricity today.

However, coal also carries a significant environmental cost with its use. When coal is burned to produce electricity, it emits air pollutants in the form of oxides of sulfur, nitrogen and carbon into the atmosphere. The oxides of sulfur and nitrogen can contribute to acid rain and smog. And the oxide of carbon in the form of carbon dioxide (CO2) is a green house gas that can contribute to global warming.

Steam generator technology – the critical component

At the heart of every coal plant is the steam generator, which converts the energy stored in coal into high quality steam needed to drive a steam turbine generator for efficient production of electricity.

The steam generator is the most critical component in our energy future since it allows us to unlock the energy value of coal, but also determines the environmental impact or cost we pay for this value. Improving its environmental performance is the most important thing we can do for ourselves and the environment.

CFB technology

At Foster Wheeler, we have developed a different steam generator technology called Circulating Fluidized Bed (CFB). Unlike conventional steam generators which burn the coal in a massive high temperature flame, CFB technology doesn’t have burners or a flame within its furnace. It utilizes fluidization technology to mix and circulate the fuel particles with limestone as they burn in a low temperature combustion process.

The limestone captures the sulfur oxide pollutants as they are formed during the burning process, while the low burning temperature minimizes the formation of the nitrogen oxide pollutants.

The fuel and limestone particles are recycled over and over back to the process which results in high efficiency for burning the fuel, capturing pollutants and for transferring the fuel’s heat energy into high quality steam used to produce power.

Due to the vigorous mixing, long burning time and low temperature of its combustion process, CFBs can cleanly burn virtually any combustible material; greatly surpassing the fuel limitation of conventional combustion processes. Unlike conventional steam generators, CFBs capture and control harmful pollutants during the burning process and don’t need to rely on add-on pollution control equipment.

(Click to enlarge image) Figure 2 — Foster Wheeler 500 MWe supercritical Circulating Fluidized Bed power plant

To further improve the CFB’s environmental report card, we have applied highly efficient vertical-tube, supercritical steam technology to our utility scale CFB designs. Supercritical steam technology allows more of the fuel’s energy to be transferred to the steam. This improves power plant efficiency, reducing the amount of fuel needed for electricity production and further reducing air emissions.

The carbon issue

Global warming and the emissions of greenhouse gases, like CO2, to our atmosphere is a relatively new concern in the world. Significantly reducing our carbon footprint while maintaining or improving our standard of living is probably the biggest challenge the human race has ever faced, since almost every thing we do from heating our homes, putting food on our tables, power our businesses, travelling, as well as, breathing, emits CO2.

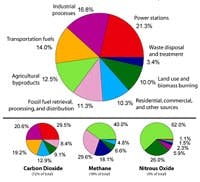

(Click to enlarge image) Figure 3 — Annual greenhouse gas emissions by sector

CO2 is not normally harmful to any life forms. In fact, it is an integral part of nature’s life cycle. Humans and animals breathe in oxygen and exhale CO2, while plant life does the opposite. Burning large amounts of fossil fuels (coal, natural gas, oil) in our power, transportation and industrial sectors has upset nature’s CO2 balance causing the level of CO2 to increase in our atmosphere. Since CO2 is a greenhouse gas which can hold the sun’s heat within our atmosphere, it contributes to global warming which is a significant concern in the world today.

The production of electricity is a significant source of greenhouse gas emission, contributing about 21% to the total greenhouse gases we emit to the atmosphere. Unlike other pollutants, CO2 is an essential byproduct of the fossil fuel combustion process and can only be reduced by burning less fossil fuel.

Addressing carbon

Due to its ability to burn carbon neutral fuels like biomass, CFB technology offers a unique solution to the CO2 issue. Biomass is considered carbon neutral since it absorbs and stores carbon from the atmosphere during its growth cycle through the natural photosynthesis process. When biomass is burned, it releases the same carbon back to the atmosphere, resulting in nearly no net carbon emission to the atmosphere.

However, due to the world’s limited and undeveloped biomass supply chain, biomass power plants are practically limited to about 25-50 MWe in size. The plant’s small scale, coupled with its fuel supply limitation translates into electricity costing about 20-30% more than that from conventional fossil power plants.

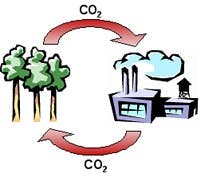

(Click to enlarge image) Figure 4 — Biomass power CO2 cycle

Again, the CFB offers a solution. Due to its fuel flexibility, a large scale (300 MWe or larger) CFB power plant can be built to burn a combination of coal and several types of biomass. This solution captures both the environmental benefit of reducing CO2 emissions and the economic benefit of providing affordable electricity. It is also flexible enough to utilize more biomass when it is available or fall back on coal when it is not to meet consumer demand.

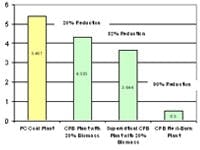

This concept can produce a substantial reduction in CO2 emission. A supercritical 600 MWe CFB plant burning 20% biomass is estimated to produce 32% less CO2 emission than a conventional coal plant. The good news is that this can be done today while still producing affordable electricity.

Addressing carbon with technology

While a 30% reduction in CO2 emissions is a big step in the right direction, projections show that we need to do much more to significantly reduce the risk of global warming6. What makes this task so challenging is that our CO2 emissions are tied to our energy use and to realize any reduction in CO2, we must first offset all new emissions connected to the growth in our energy use.

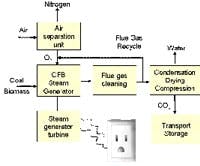

To take carbon reduction to the next level, Foster Wheeler is developing Flexi-Burn CFB technology. Flexi-Burn will allow the CFB to produce a CO2 rich-flue gas and be part of a practical carbon capture and storage solution (CCS). The technology has the potential to reduce coal plant CO2 emissions to the atmosphere by over 90% while minimizing the cost impact and technology risk to consumers.

Instead of using air in the CFB combustion process, Flexi-Burn technology uses a mixture of oxygen and recycled CFB flue gas. By doing this, the flue gas becomes rich in CO2 (containing over 90% CO2 on a dry basis), rather than rich in nitrogen as when air is used. Since its flue gas is nearly all CO2, Flexi-Burn CFB technology doesn’t need expensive and energy intensive equipment to remove the CO2 from its flue gas and has the potential to produce carbon free electricity at a very low cost as compared to other technologies.

(Click to enlarge image) Figure 5 — CO2 air emissions from a 600 MWe plant (Mtons/yr)

But the challenge goes well beyond capturing CO2 from coal power plants. Transporting and storing CO2 in under-ground locations, like saline aquifers, is not proven and requires years of study to understand the cost and risks of doing this. And no one really knows how much consumers are willing to pay for (or can afford) truly carbon free electricity. Due to the uncertainty of carbon regulation, the cost and risk of CCS technology and consumer behaviour, it is nearly impossible to predict when wide scale market acceptance of CCS power plants will occur.

To cope with the market uncertainty from a technology aspect, Flexi-Burn has been designed for market flexibility. The plant can operate in either economical air mode (as all coal plants operate today), providing affordable and competitive electricity to today’s market, or in CCS mode without requiring any significant modification to the plant. This gives power producers the flexibility to adjust plant operation with a changing and uncertain market for carbon free electricity and will likely allow faster adoption of CCS technology.

(Click to enlarge image) Figure 6 — Flexi-Burn CFB technology diagram

Flexi-Burn also provides investment flexibility by allowing the plant to be built in functional stages. The plant can be built first for full functionality in the economical air mode, allowing power generators to defer the CCS portion of the plant’s capital investment until it is justified by market and policy conditions. This flexibility will allow investment into the power capacity we need to meet our growing demand while giving investors the

As we are seeing today, the uncertainty surrounding the carbon issue is preventing needed investment in our power generation infrastructure. This hurts not only the consumer but the environment as well. Without, new modern power plants coming onto the grid, power generators have no choice but to keep relying on old, inefficient and polluting power plants to meet consumer demand.

Circulating fluidized bed technology is an important part of the solution to meet the world’s energy needs while conserving natural resources and preserving our environment.

References

1. International Energy Outlook 2008. June, 2008. Energy Information Administration.

1/07/2009. http://www.eia.doe.gov/oiaf/ieo/electricity.html.

2. Energy Statistics: Electricity>Consumption. 2007. Nation Master.com. 1/07/2009.

http://www.eia.doe.gov/oiaf/ieo/electricity.html.

3. All About Coal. 2007. The American Coal Foundation. 1/14/2009.

http://www.teachcoal.org/aboutcoal/articles/coalppf.html.

4. Annual Greenhouse Gas Emissions By Sector. 2007. Emission Database for Global Atmospheric Research. 1/05/2009. http://www.teachcoal.org/aboutcoal/articles/coalppf.html.

5. CO2 Emissions from a 600 MWe Plant. January, 2009. Foster Wheeler Research and Development Team.

6. What Will it Take to Stabilize Carbon Dioxide Concentrations? June, 2008. Energy Information Administration. 1/22/2009. http://www.eia.doe.gov/oiaf/ieo/scdc.html.