Anyone who has heard a refrigeration unit groan through a brownout or been frustrated by an inexplicable series of control system trips should have a healthy respect for the effects of power quality on equipment reliability and energy efficiency. Few doubt that sags and harmonics contribute to downtime, off-spec production and shortened equipment life.

But, like so many potential projects that improve uptime, product quality and life cycle cost, it’s hard to make a financial case for spending on power conditioning. These days, it’s much easier to gain support and financial backing for the rapid paybacks you can calculate from improving energy efficiency.

“Power-quality solutions have historically been sold as insurance policies to protect against the next damaging sag, surge or interruption,” says Daniel Carnovale, P.E., power quality solutions manager, Eaton (www.eaton.com). “Those benefits are hard to justify. By contrast, energy savings offers easy justification.”

The problem is that some of the solution providers significantly overstate the savings and customers are deceived. Carnovale says, “While these solutions provide excellent protection, they often provide very little, if any, energy savings.”

Common sense as well as the Electric Power Research Institute (EPRI) point out that you can only save energy that is wasted. The losses in a typical plant power system range from 1% to 4%, so eliminating them would, at best, reduce your bill by 1% to 4%.

But these days, even a couple percent of energy savings can add up to a worthy return on investment, and paying attention to power quality in the form of power factor and peak demand can reduce some industrial power bills as much as 30%.

Sources of savings

Sags, surges, interruptions and harmonics wreak havoc on equipment. It’s easy to believe they contribute to inefficiencies, and they do. But how much?

You might find low-hanging fruit in your existing power quality or uninterruptible power supply (UPS) equipment. Strides have been made in the efficiency of the rectifier stages that condition incoming power and connect capacitors or batteries to support sags and outages. Just a few years ago, “Typical losses were 10% to 15%, and worse at lighter loads,” says Ed Spears, product marketing manager, critical power solutions, Eaton. “Now we are in the range of 92% to 98%, even 99% efficient. This from better semiconductor technology but also topology. We can operate in modes where we can allow more straight utility power to come through.”

From there, savings directly from reducing inefficiencies drop off rapidly. For example, in motors, “A 3% voltage imbalance can lead to a 25% to 30% current imbalance, and increase motor losses by 10% to 20%. It also raises motor operating temperatures,” says Mike Melfi, manager, advanced variable-speed motor technologies, Baldor (www.baldor.com). But the increase in loss might not add up to much. “Altogether, a 95% efficient motor might be reduced to 94%,” Melfi says.

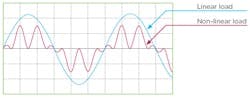

Figure 1. Harmonics are multiples of the fundamental frequency (60 Hz in North America), and are produced by nonlinear loads.

Harmonics are multiples of the fundamental frequency (60 Hz in North America), and are produced by nonlinear loads (Figure 1). “Unwanted harmonics equal heat, which equals loss,” says John Perry, product marketing manager, power factor correction products, Eaton. “Wiring sizes, conduits and other components can be minimized by minimizing harmonics.”

Ironically, some energy-saving technologies such as electronic lighting ballasts and variable-speed drives (VSD) can add harmonics, as can computer power supplies. These cause inefficiencies and shorten the lives of motors, transformers and other connected equipment. Even when the phase loads are balanced, “The third harmonics can add up in the neutral conductor,” says Rich Vesel, product manager, electrical balance-of-plant equipment, ABB. (www.ABB.com). “At 60 Hz, the neutral currents of a balanced three-phase system cancel, but the third harmonics don’t cancel — they add. An undersized neutral can run hot and might even become a fire hazard. Balance the phases, oversize the neutral line, and use harmonic filtering to minimize the effects.”

Furthermore, some of the ways plants deal with harmonics add to energy inefficiencies. “People used to throw in K-rated transformers all over the place because harmonics were eating up their standard transformers, but they would lose 2% to 4% efficiency,” says Carnovale. “Newer versions are much more efficient, and they handle the harmonics — they can absorb them like a capacitor set. You can use them in pairs to cancel out harmonics.”

The upshot is, while cleaning up power might pay off in higher system efficiency, that’s not where you’ll find 25% savings. “Companies want to install a black box and save a lot of energy, but unless they have a power factor situation and the utility is imposing a penalty, they’re not going to save 20% to 30%,” Carnovale says. “If they replace an inefficient UPS, they might pick up 10%. For harmonics, it’s going to be more like 2% to 4%.”

Understand power factor

Finding the proverbial 20% to 30% reduction in electricity bills doesn’t require an electrical engineering degree, though you might need to consult with a few to obtain your goal. So it’s worth having at least a rudimentary understanding of active power (also called true power), reactive power, apparent power and power factor.

Active or true power (P) is measured in watts (W) delivered into a resistive load and converted into mechanical work or useful heat.

Reactive power (Q), measured in volt-amperes reactive (VAR), is the power that energizes magnetic fields of inductors (coils) and charges capacitors. Motors, transformers and capacitors require VARs. Creating and collapsing the magnetic fields occurs within each half cycle. “Power engineers speak of motor loads as consumers of VARs and capacitors as suppliers of VARs,” says Harry Boulos, sales manager, Power Quality Group, Schneider Electric (www.reactivar.com).

“Reactive power doesn’t perform measurable work, but it loads the power-generating and transmission equipment the same as if it did,” Vesel says. “So, the power company has to support both types of load.”

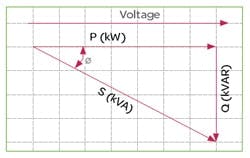

Figure 2. The active power component (P) is in phase with the applied voltage while the reactive component (Q) is 90º out of phase. The power factor (PF) is defined as the cosine of the angle between active power and apparent power (S). From the power company’s perspective, the closer the power factor is to unity, the higher the efficiency of the electrical system.

Apparent power (S), measured in volt-amperes (VA) or kilovolt-amperes (kVA), is the vector sum of the active and the reactive components (Figure 2), and represents the system capacity required to support the active plus reactive loads. Power transmission lines and transformers must be sized in kVA to supply the total VARs and watts.

Power factor (PF) is the ratio of active to apparent power (W/VA).

The utility is paid by the kilowatt-hour (kWh) for real power, and charges a fee based on the peak demand represented by the combination of real and reactive power. “If a plant has a large reactive load because of poor power factor control, along with the price of the power, you’re paying rent on an oversized ‘pipe’ to deliver it,” Vesel says.

The demand fee might not be explicit. “Sometimes it’s obvious, sometimes not,” Perry says. “If your bill includes terms like kVA or kVAR, they’re measuring your power factor and they might be charging for it with a surcharge that shows up on your bill.”

Power factor penalties take a variety of forms, calculated in different ways that are detailed in the white paper “Power Quality Solutions and Energy Savings — What Is Real?” at www.eaton.com/experience. Some utilities use multiple methods and might apply more than one penalty.

A power factor penalty might be invisible. “For example, in a straight kVA demand rate, there is nothing that explicitly mentions a power factor penalty,” Carnavale says, “but a poor power factor will result in a higher kVA for a given kW of load, so there is an implicit power factor penalty built into that rate. In other cases, the utility might give a rebate for maintaining a power factor above a given level. You might not realize you are paying a penalty if you don’t get this rebate.”

Customers of intermediaries such as municipalities or co-ops might find that penalties are simply buried in the demand charge. “The power factor penalty might be levied by the power supplier to the co-op and the penalty adjusted in the demand charge,” Carnovale adds. “It might look like a reduction in kWh when the penalty is removed.”

Be proactive about reactive

Your power factor penalty is typically determined by utility measurements of average reactive power during 15-minute or 30-minute periods throughout your billing cycle. You can reduce or eliminate the charge by balancing loads or using power factor correction equipment. But, you say, this isn’t news — didn’t you take care of that back in the 1980s with a set of tapped capacitors?

Maybe you did, but those were simpler times. “Loads have changed tremendously,” Boulos says. “VSDs, presses, welders and automation together cause problems on the network. With cyclic loads, traditional correction with a fixed capacitor, or even with a controller averaging every 30 seconds or every minute, doesn’t always work.”

VSDs offer higher system efficiency but can aggravate plant power quality and reduce the reliability and efficiency of fixed-speed and constant-torque motors on the same power supply. “The net energy savings can be reduced by these effects,” says John Malinowski, senior product manager, AC and DC motors, Baldor. “The drive design can help or hurt, and this is true of any load. Hence IEEE Standard 519, which is driven by reliability considerations but applying it also affects energy efficiency.”

So one strategy is to be selective about the technologies you install. VSDs with active rectifier units (ARUs) compensate for other inductive loads on the same power supply or bus — for example, in a group of motors on a bus where one or more run at full power and speed, a motor with an ARU can compensate the inductive loads of the full-power motors and correct the bus power factor. “It’s best to consider only drives with active front ends, where you can control reactive power and power factor,” Malinowski says.

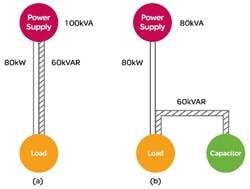

Figure 3. In this example, supplying the reactive power locally with a capacitor brings the power factor to unity and reduces the power supplier’s apparent load from 100 kVA to 80 kVA.

If today’s drives aren’t enough, separate power factor correction devices can improve overall electrical efficiency upstream of their point of connection in the electrical network (Figure 3). “The most basic example is a set of capacitors you switch in or out manually depending on the equipment that is running,” says Vesel. “Static VAR compensation (SVC), or STATCOM, might be applied at the substation.”

However, you can’t indiscriminately add power factor correction capacitors without understanding how their presence will affect the system. VFDs, DC power supplies, electronic ballasts and other nonlinear loads can cause harmonics, which can interact with the inductive reactance to cause harmonic resonance.

“Harmonic resonance is said to be a self-correcting problem,” says Carnovale. “Most times capacitor fuses will open, capacitor cans will fail, or the source transformer fails. Any of these events will lead to the removal of a component from the system, eliminating the resonance condition. However, they’re all undesirable results. In a best-case scenario, the electrical control equipment acts erratically.”

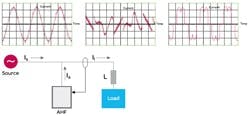

The interactions call for combining corrections for harmonics and power factor. For example, an active harmonic filter (AHF) can be part of a power factor correction system (Figure 4). Some potential benefits of a holistic approach include:

- Additional production without buying transformers and distribution equipment by reducing the power factor.

- Ensuring compliance with the utility’s harmonic standards.

- Improving reliability of the distribution network and process equipment, for example by eliminating logic faults of digital devices.

- Reducing overheating of transformers, motors and cables.

Figure 4. An active harmonic filter (AHF) senses dynamic power-quality problems and injects the appropriate harmonic and reactive current to limit harmonic distortion and improve power factor. The result is a nearly perfect sine wave.

Keeping up with loads that vary throughout the production cycle might require faster, automated equipment, like a hybrid VAR compensator. It has a passive component that works like a fixed capacitor, and a high-speed active component. It can act as needed as a leading, lagging or inductive load, and respond quickly to support voltage. “They can save more energy than folks think they will,” says Boulos. “Mars is saving an average of 5% at multiple facilities, where you’d traditionally expect a savings of 2% to 3%.”

The potential savings depends on the kind of equipment. An automaker would expect more savings with welding and stamping equipment than in painting or assembly. In the steel industry, it’s arc furnaces. Each part of the plant is a little different.

“It’s best to have someone visit and see what the problems are,” Boulos says. “Are they sags or transients? We look at the loads and, if needed, set up a study and take measurements. Then we can make recommendations and a proposal.” Paybacks typically are one to two years for a normal capacitor system, two to three years for a filtered system. “But reduced downtime and product savings by reducing scrap can make it less than a year, sometimes less than six months,” Boulos adds.

Know where it’s going

The first step toward improving energy efficiency is to know where your energy is going, and suppliers are supporting this measure by rapidly improving the capabilities and reducing the costs of power monitoring systems.

Monitoring systems are being used to look at power quality, sequence of events, trends in loads, temperatures and currents, and more. “We have a million boxes — relays, meters, current transformers — to go into any power system,” says Vince Tullo, general manager, sales, GE Digital Energy (www.gedigitalenergy.com). “From inputs to motor control centers — substations, switchgear, protective relays — you have, at every point, the ability to put on intelligence. You can have control, metering and fault detection all in one box.

“But it’s not the boxes, it’s the ability to take that data, turn it into information and give it to the right person in an actionable format,” Tullo continues. “The news during the past few years is the ability to get information down to the process level and be able to use it.”

To make educated decisions about corrective equipment for mission critical operations, Eaton says a monitoring system should be capable of:

- Capturing triggered events like sags, swells, and interruptions (many energy meters only captured time triggered data not threshold triggered data)

- Evaluating real-time and snapshot data for key electrical and power quality variables

- Having sufficient frequency response and sampling rate to capture high-speed transients such as events related to lighting or switching

- Trending appropriate variables so a change or variation from normal is obvious and can be flagged and used for analysis.

- Trending harmonic currents and voltage distortion to evaluate issues related to harmonics (overheating, nuisance operation or capacitor failures)

- Time/date stamping events to within one millisecond to help determine the correlation between cause/effect

“Electric power distribution units (EPDUs) can monitor and control, and be set to alarm on overload or unbalance, to help maintain efficiency and prevent failures,” says Perry. “By monitoring breakers and submetering components, you can catch negative trends to save energy and downtime.”

A well-instrumented and characterized power system can be modeled for more effective monitoring, engineering and maintenance. “Users can simulate, understand, and re-engineer the way their entire electrical infrastructure will respond in the event of unexpected faults or routine system maintenance,” says says Mark Ascolese, CEO, EDSA (www.edsa.com). “You can detect variations between as-designed specifications and actual electrical system performance so you can predict potential points of failure and ensure that facilities operate as they were designed to, down to the smallest component.”

A breaker removal or other maintenance on mission-critical equipment might typically have to be done at night or over a weekend or holiday to allow for surprises. “With simulation capabilities, you can see the effects, practice the operation and do it anytime without worrying about unknowns,” Ascolese says. “Modeling lets you see how changes would affect energy bills — whether doing something different would save energy and cost. You can look at shifting assets from peak to off-peak times and see what the effects would be.”

Shave a peak

With harmonics under control and a plan to keep power factors close to unity, you’re ready to work with your utility to reduce peak loads and shift non-critical power consumption to off-peak times. Your power company might offer to help pay for it.

Sags can be filled and peaks can be shaved with energy storage devices. Flywheel systems are used on material handling cranes, connected to the DC section of a VSD. “During lift, power usage peaks and the DC bus can sag, but during let-down, there’s energy available for regeneration,” says Frank DeLattre, chief sales officer, Vycon (www.vycon.com). “That energy can be stored and used during lifts to reduce consumption.” The devices also provide power for a short time during outages.

Energy storage also can be used to cover peak loads where capacity is limited, such as at the end of a heavily loaded power transmission line or a location where the substation has become marginal. “You can draw more than the utility can provide during short peaks, and use the flywheel to prevent a voltage sag,” DeLattre says.

“Clients like Valero Oil, BASF and Publix are putting in load-shedding systems to reduce peak loads and handle outages,” Tullo says.

When hurricanes take out the power lines, Publix food stores are shut down — no lights, no registers, and soon, the food spoils. So they put in standby power systems with generators. “Now, when a hurricane comes through, they stay in business, but more importantly, they also manage their peak demand,” Tullo says. “On hot summer days, they run the generators and sell excess capacity back to Florida Power and Light.”

Typical paybacks are 12 months to 18 months for load-shedding and critical power initiatives, Tullo says. “They’re spending money to save money.”

Utilities often have formal demand-side reduction programs where they invest as much to reduce demand as they would have to spend to increase capacity. “Some have called them ‘dollar-a-watt’ programs,” Vesel says. “Talk with your utility. Get your plant audited by people who know how to do it right and can give you a well-analyzed and well-engineered result, and go from there.”

E-mail Editor in Chief Paul Studebaker, CMRP, at [email protected].