In these troubling times, most maintenance departments must make difficult economic decisions. For manufacturing companies, one of the first areas to go under that microscope is maintenance. To the unsophisticated, maintenance costs, both labor and parts procurement, seem easy to scale back during economic downturns. Preventive maintenance tends to drift toward maintenance-by-emergency.

A well-planned V-belt maintenance-reduction program can help you survive while minimizing equipment degradation. The planning process doesn’t have to be a protracted agony. Using simple processes and some tailored resources will deliver good results.

If you’ve developed a decent CMMS database or manual paper proactive maintenance system, you have already benefited from reduced labor and parts replacement costs (prevent a catastrophic failure), reduced production downtime and maximized energy savings (minimized belt slippage).

Proactive maintenance can be scaled back, but that involves significant risk-taking. Obviously, maintenance can be eliminated on idled equipment. However, scaling it back on operating equipment risks reversing the benefits listed above. This is especially true if the cutbacks are made without a rational thought process.

Reducing a maintenance program to the “if it ain’t broke, don’t fix it” level will result in significant degradation of equipment condition over time, costly major repairs and production downtime. That last effect might not seem like a major issue during reduced production schedules, but you can bet money that it’ll be a critical machine that will break down at midnight while production is working to fill that oh-so-important order that must be delivered on time.

Test low-cost suppliers

Before we explore possible ways to tweak your V-belt maintenance program, let’s discuss belt-purchasing practices. In tough times, purchasing always seeks alternative, low-cost vendors. In the case of belts (both V-belt and synchronous or timing belts), there are inferior-quality imported belts being sold in the United States. I’ve visited some of these plants and the astonishingly poor quality amazed me. The manufacturers often will claim to meet the standards of the either the Rubber Manufacturers Association (RMA) or ISO. The problem is that these standards are geometric standards, not performance standards. They define belt and pulley dimensions and tolerances. In the case of RMA, the organization publishes horsepower ratings, but no performance qualification method. Any manufacturer can claim that its belts meet the ratings, but there’s no way to confirm the claim. An inferior product will manifest itself in drastically reduced belt life and significantly greater maintenance demands. In the long run, purchasing name-brand belts from industry-recognized distributors is money well spent.

If purchasing wants to evaluate alternative, low-cost suppliers, it should be done in a premeditated manner. Maintenance should be involved and select one or two challenging applications so that the belts will be evaluated properly in a real-life application. This teamwork will allow purchasing to evaluate the prospective vendor properly. The goal of a test program shouldn’t be one of ranking vendors; that takes many months or years and requires considerable testing in many applications. Rather, the test program should help you gain assurance that the potential vendor isn’t furnishing a vastly inferior product. The cheap belts will likely fail after a month or two on a challenging drive, as opposed to two to three years for a quality belt installed on a properly designed and maintained drive. Preliminary evaluation can be based on inspecting the belts for unusual wear or cracking, and any additional required maintenance. If the prospective vendor’s belts last for a month or two, up the ante and expand the evaluation to additional drives, again selecting challenging candidates.

Collect data to reduce maintenance

Reduce your belt maintenance in a systematic manner. This doesn’t have to be a huge undertaking. The primary information source supporting your logical decision process is your CMMS or paper-based work order databases. Then, augment that data with input from the mechanics and machine operators. Group your equipment into logical categories, for example:

- Belt drives on active equipment with no history of service problems are candidates for deferred maintenance.

- Belt drives on idled machines or those that have reduced usage are candidates for deferred or “no maintenance” status.

- Belt drives on critical machines exhibiting minimal service problems should be subjected to an analysis of risk versus cost before instituting an extended maintenance schedule.

- Belt drives on critical machines with a history of significant service needs will require a review of maintenance procedures, product quality level (look for use of off-brand belts) and a request of your vendor for recommend remedial options.

- Belt drives that are trending toward increasing maintenance demands will need to be prioritized for a failure analysis if resources are available or the component vendors can make recommendations.

This process will likely identify some troublesome belt drives. If these belt drives are on important production equipment, they probably justify a first-level troubleshooting process. A belt drive that is both designed and maintained well in a reasonable factory environment should last from two years to three years. The most frequent causes of reduced belt life are:

- Improperly designed drive

- Belts of inferior quality

- Improper maintenance with respect to tension, misalignment, etc.

- Worn pulleys

- Abnormal heat, dust, chemicals, etc. in the operating environment

- Improper belt storage in the stockroom

Use the right tools

A skilled, trained mechanic can do some troubleshooting on a drive that isn’t performing up to expectations, but a good belt vendor with whom you’ve built a partnership often can assist in troubleshooting. They’re better equipped for the process. Troubleshooting a belt drive requires various tools. Those commonly available in the plant include:

- Infrared thermometer (belt temperatures should generally be less than 140ºF)

- Stroboscope to observe belts under all operating conditions (with emphasis on start-up, shock loads and shut-down)

- Straightedge (or string for drives with long center distances) to check both parallel and angular misalignment (Figure 1).

Figure 1. Use a straightedge or a taut string to look for misalignment.

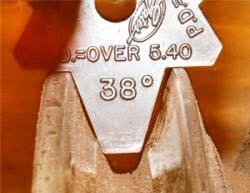

Advanced tools include a thermal imager and vibration analyzer. Some inexpensive tools you might want to add to your arsenal include groove gauges to check for sheave and belt wear (Figure 2), a belt-tension gauge (Figure 3) and the belt vendor’s preventive maintenance manual. These are available from your belt vendor, who will show you how to use them. Preventive maintenance manuals, your primary guide for maintaining and troubleshooting belt drives, might be available on the belt manufacturer’s Web site. The manual should provide generalized tension recommendations and lead you though the troubleshooting process.

Figure 2. Use a groove gauge to help visualize sheave wear.

Figure 3. The tension gauge should be used for proper drive tensioning.

A most versatile tool

One final “tool” that will prove extremely valuable in your efforts to reduce belt maintenance is the machine operator. Typical operators know their machines inside out. Encourage them to monitor their equipment using their full range of senses:

- Watch for signs of abnormal operation

- Listen for unusual noise that could signal pending problems

- Observe unusual scents (probably an overheated component on the verge of failure)

- Feel for unusual machine vibration

Give your operators the authority to shut down a machine they believe has a significant probability of a major failure. It’s better to have one or two false alarms than one major failure that damages associated equipment.

Done properly, scaled-back maintenance can help you survive and be prepared when the economy improves and orders pour in.

Jim Shepherd is chief engineer (retired) at The Gates Rubber Co. Contact him at [email protected] and (303) 478-3501.

Figures: The Gates Rubber Co.