|

View related content on PlantServices.com |

Polyurethane’s elastic properties, mechanical strength and wear resistance make it a good material for pneumatic seals. When the polymer’s composition and design development are tuned to the specific demands of pneumatic applications, modern polyurethane pneumatic seals shift operating limits to new levels. This has been validated by rigorous testing and validation.

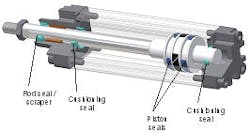

Pneumatic actuators are key elements of material-handling and automation systems used for moving, clamping and positioning goods, boxes, flaps, gates, etc. A typical pneumatic cylinder (Figure 1) contains several static and dynamic seals. The dynamic seals are:

- Double-acting piston seal (often two U-cup seals)

- Rod seal and dirt wiper (often combined in one element)

- Two cushioning seals for the adjustable pneumatic end cushioning.

Figure 1. This cutaway model of a pneumatic cylinder, cutaway model shows the basic components covered below.

- Oil-free compressed air using only the minimal grease lubrication that was applied during cylinder assembly

- Operating pressures to 100 psi with excursions to 360 psi during cushioning

- Creep velocity of 3+ ft./sec.

- A temperature range of -4°F to +176°F

With a typical cumulative lifetime travel of at least 4,000 miles, the area of dynamic contact must maintain grease lubrication. A flexible sealing lip geometry provides low radial forces, and a rounded contact area allows the lip to float on a grease film.

If hydraulic seals were used in pneumatic cylinders, the high radial force and sharp sealing edges would scrape the grease away from the contact area. The grease would collect at the ends and the ensuing poor lubrication would result in high friction, heavy wear and shortened useful life.

Seal design refined

The seal design follows the principles described above. Additional features ensure proper function under any operating condition.

Piston seal: U-cup-type piston seals have been used in pneumatic cylinders for many years. The design in Figure 2 has several special features. It has a thin connection between sealing lip and body to achieve low radial force. Toward the contact area, the lip is larger to give stability under pressure.

Figure 2. This piston seal provides stability in the contact area and minimizes radial forces that can affect cylinder movement.

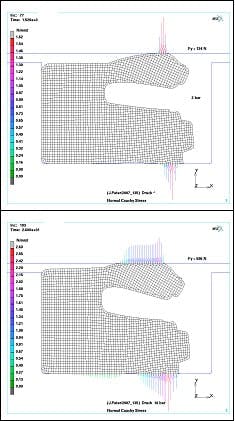

Notches at both lips and on the outer diameter of the back side avoid malfunctions. The notches on the side of the outer sealing lip ensure proper activation when the pressure increases. Notches at the outer diameter of the back (not shown in Figure 2) and on the inner lip act as pressure-release channels in case pressure is trapped between the two U-cups in a double-acting piston. Without these notches, a pressure trap, together with friction, can tilt the seal in the groove, which results in an inoperable cylinder. The rounded contact area of the sealing lip was optimized by finite element analysis to ensure good function over the whole pressure range (Figure 3).

Figure 3: Finite element analysis result of the lip seal reveal its performance at 29 psi and 145 psi.

A polyurethane material was developed for the specific demands of pneumatic applications. The 83 Shore A hardness is relatively low to minimize the radial force. With its good compression set, low friction and extraordinary wear resistance, it provides the preconditions for good functional properties and long service life.

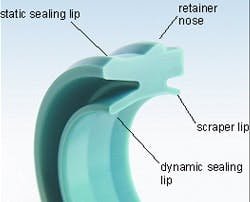

Rod seal: The rod seal (Figure 4) is designed to suit grooves for pneumatic cylinders to ISO 15552. The seal has a sealing lip and a dirt wiper lip, and is fixed by a retainer “nose” at the outer diameter. The seal can be mounted into an unsplit gland by pushing it into the bore until the retainer nose snaps into the mating groove of the housing bore. The outer, static sealing lip is chamfered for ease of installation.

Figure 4. The nose on the rod seal/scraper ensures proper installation.

As the seal is fixed only by its retainer nose, the seal material must be stiff enough to withstand the axial forces of pressure and friction. Therefore, a harder material (94 Shore A) is used to maintain the proper seal orientation.

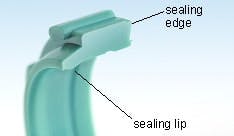

Cushioning seals provide smooth piston movement at the dead-end positions. The cushioning seal (Figure 5) works better than O-rings. The specific design features are:

- Dynamic sealing lip gives good tightness and low friction

- Axial sealing edge with check valve functionality

- Combined notches at the lip side and on the outer diameter to allow air flow

Figure 5. The cushioning seal protects the cylinder from end-of-travel shocks.

Tests validated performance

A test program performed with commercially available pneumatic cylinders confirmed the material and design-development efforts. The cylinders were equipped with a rod seal-scraper, two piston seals and two cushioning seals. The test program included:

- High-pressure test

- Bursting pressure test

- Low-temperature test

- Temperature cycling test

- Minimum speed test

- Endurance test

The test procedures reflected harsh, but realistic, operating conditions using oil-free compressed air with an oil content < 0.01 mg/m3 (class 1 to ISO 8573-1). Testing monitored two indicators of seal functionality: the leak rate at two pressure values (29 psi and 145 psi) and the break-off pressure in both directions. The break-off pressure is the minimum pressure needed to move the cylinder. It’s different for outstroke and return stroke because the pressurized area of the cylinder is smaller on the rod side.

High-pressure test: This test reflects the situation at peak pressure during the cushioning cycle. To avoid having to produce and dissipate excessive energy, the test equipment included a pressure intensifier to generate an operating pressure of 360 psi. The cylinders have a short stroke of 0.59 in. to simulate only the cushioning cycles. Special high-pressure lines and high-pressure valves are used.

After 100,000 cycles, the sealing function wasn’t compromised by physical damage, seal wear or leakage. Break-off pressure was the same as when new. The sealing system proved its robustness and reliability even under extreme pressure peaks during the pneumatic end-cushioning cycle.

Bursting pressure test: This test confirms seal robustness and safety in case of abnormally high pressure. For the rod seal, this test shows the safe fixation by the retainer nose. The cylinders functioned at the target pressure of 725 psi without problem. The first leakage occurred at 942 psi, when the rod seal was partly extruded out of the housing, but no seals were damaged. After re-installing the rod seal, the cylinder was fully functional with a leak rate and break-off pressure the same as new.

Low-temperature test: This test shows the minimum temperature under which the cylinder functions properly. The cylinders were installed in a temperature chamber and connected to an external measuring station to enable measuring of leak rates and break-off pressure. An additional air dryer helped avoid water accumulation in the system. After cooling down the system, the measuring was done quickly to avoid frictional heating that would affect the result.

The low temperature limits of the piston seals depend on their location on the piston, although the two piston seals are identical. The piston seal at the bottom of the cylinder is the most critical position because it is measured with the rod extended, when the guidance clearance causes a misalignment between the piston and the cylinder tube. The piston seal at the rod side is measured with the rod retracted, when piston and cylinder tube are in good alignment. Under such good conditions, the piston seal works well at lower temperatures. So, the degree of misalignment leads to a low-temperature limit between -4°F (piston seal bottom side, rod extended) and -22°F (piston seal rod side, rod retracted). The rod seal is tight down to -40°F because the volume shrinkage from temperature reduction helps to keep the lip in sealing contact.

To summarize, testing showed that the pneumatic cylinder remains fully functional down to -4°F under worst-case conditions, and down to -13°F under normal conditions.

Temperature cycling test: This test cycles between minimum and maximum operating temperature to show the seal material’s ultimate behavior. The test equipment was the same as for low-temperature testing. Temperature cycling revealed no leakage and no change in break-off pressure, which proves that frequent changes of operating temperatures don’t affect the service life.

Minimum speed test: This test explores a cylinder’s operation at creep velocity. The cylinder, equipped with a side-load weight, is pressurized on one side while a throttle valve on the other side is closed until the cylinder begins to exhibit stick-slip mode.

This test is relevant to polyurethane because its higher modulus gives higher stick-slip tendency compared to nitrile-butadiene rubber. The cylinder is connected to a position-measuring system, which records the movement . After five cycles of running-in, the air outlet throttle is closed stepwise until the minimum speed without stick-slip is found.

For a moment, the cylinder stopped (v = 0). That’s already understood as stick-slip, although usual stick-slip effects are found as a permanent alternation between stick and slip and produce a vibration noise.

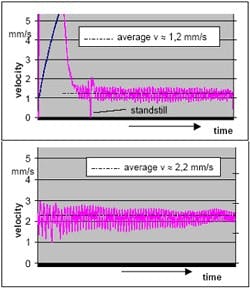

Figures 6a and 6b. The cylinder can operate at a low speed before stick-slip motion becomes apparent.

The average velocity of 2.2 mm/sec. (0.087 in./sec.) is the minimum speed without stick-slip and is significantly below the target of 5 mm/sec (0.197 in./sec.). This means that pneumatic cylinders equipped with the sealing system under test are suitable for demanding positioning tasks as well as for moving sensitive goods.

Endurance test: The endurance test is representative of a service life under harsh conditions with cylinders running continuously with side load weights and under high pressure. Every two weeks, the test was interrupted to measure the leak rate and break-off pressure.

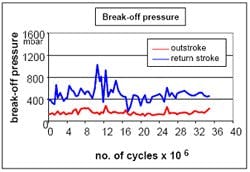

The pressure and the number of cycles were monitored automatically while the cylinders are fixed in a horizontal position. Every two weeks (about 600,000 cycles), each cylinder was tested with a high-precision pressure regulator and flow sensors to monitor the leak rates for every seal at two pressures (29 psi and 145 psi) and the break-off pressure in both directions. The endurance test was originally scheduled to be performed until the cylinders reached the maximum leak rate. After more than 36 million cycles (2.5 years), the test was stopped because the lifetime travel was already far above the expectations. A typical chart from the break-off pressure measuring of one of the seven cylinders is shown in Figure 7.

Figure 7. Break-off pressures from endurance testing remained stable long after exceeding the normal operating life.

The break-off pressure at outstroke is relatively constant at 3 psi, while the return stroke shows a higher varying value of around 7.5 psi because the pressure at outstroke acts on the whole area of piston diameter. At return, it acts on the piston diameter minus the rod diameter. So, the same pressure causes a higher axial force at the outstroke. In addition, the outstroke measurement starts with the retracted rod. The return stroke starts with the rod extended, when the guidance clearance causes an angular misalignment between tube and rod.

The leak rate values of the rod seal are constant and low during the whole endurance test. The maximum values are around 10 ml/min at 29 psi and around 20 ml/min at 145 psi, both far away from the limit of 200 ml/min. There is no tendency to an increase of leak rates toward the end of the endurance test.

Similar to the rod seal, the leak rate values of the APDF piston seal are low and constant during the whole endurance test. The maximum values are below 10 ml/min at 29 psi and around 20 ml/min at 145 psi, both far away from the limit value. There is no tendency to an increase of leak rates toward the end of the endurance test. The results of the endurance testing show the unique wear resistance of the polyurethane materials in interaction with the thoroughly developed designs.

The 36 million cycles are equivalent to a distance of 11,200 miles and the seals haven’t reached the end of their service lives. That’s around three times of the lifetime travel with nitrile-butadiene rubber seals under equal conditions. If a pneumatic cylinder with stroke length of 9.84 in. does four strokes per minute on three-shifts, five days a week, 52 weeks a year, it would need 24 years to reach a total travel of 11,200 miles.

The test results demonstrate how a sealing system can be optimized with material technology and design knowledge. The thorough consideration of functional aspects and use of latest development tools produce better performance. The material development, focused on the specific demands of pneumatic applications, was the second component of a high-performance polyurethane sealing system. Pneumatic equipment manufacturers and end users can be sure of the best functionality under extreme conditions, absolute reliability and outstanding service life. Thus, the costs for replacement and consequential costs from production shutdowns can be reduced.

Matthias Keck, Matthias Schott and Dr. Nils Kohlhase are from Trelleborg Sealing Solutions, Fort Wayne, Ind. Contact them at [email protected] and (260) 749-9631.