Maintaining variable frequency drives (VFDs) is easier than you might think. By using some basic tools and integrating some simple, logical steps into your preventive maintenance (PM) program, you can ensure your drives provide many years of trouble-free service. Before looking at those steps, let’s quickly review what a VFD is and how it works.

A quick overview

A VFD controls the speed, torque and direction of an AC induction motor. It converts fixed voltage and frequency AC input to a variable voltage and frequency AC output. Control circuitry coordinates the switching of power devices, typically through a control board that dictates the firing of power components in the proper sequence. A microprocessor or digital signal processor (DSP) meets the internal logic and decision requirements.

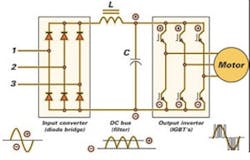

Figure 1 shows what the three main sections of a VFD are and what they do. The input section of the drive is the converter. It contains six diodes, arranged in an electrical bridge. These diodes convert AC power to DC power. The next section — the DC bus section — sees a fixed DC voltage.

Figure 1. Pulse width modulation (PWM) drives contain these main parts, with subtle differences in hardware and software components. This is a basic variable frequency drive (VFD).

The DC bus section filters and smooths the waveform. The diodes actually reconstruct the negative halves of the waveform onto the positive half. In a 460-V unit, you’d measure an average DC bus voltage of about 650 to 680V. You can calculate this as line voltage times 1.414. The inductor (L) and the capacitor (C) work together to filter out AC components on the DC waveform. The smoother the DC waveform, the cleaner the output waveform from the drive.

The DC bus feeds the final section of the drive: the inverter. As the name implies, it inverts the DC voltage back to AC. But, it does so in a variable voltage and frequency output.

How does it do this? That depends on the type of power device your drive uses. Bipolar transistor technology began superceding thyristors (SCRs) in drives in the mid-1970s. In the early 1990s, those gave way to insulated gate bipolar transistor (IGBT) technology. Today’s inverters use IGBTs to switch the DC bus on and off at specific intervals. In doing so, the inverter actually creates a variable AC voltage and frequency output. In very small VFDs, a single power pack unit may contain the converter and inverter.

From this description, you can see a VFD is basically a computer and a power supply. And the same safety and equipment precautions you’d apply to a computer and a power supply apply here. Drive maintenance requirements fall into three categories:

- Keep it clean.

- Keep it dry.

- Keep the connections tight.

Keep it clean

Most VFDs fall into the NEMA 1 category (side vents for cooling airflow) or NEMA 12 category (sealed, dust-tight enclosure). Drives that fall in the NEMA 1 category are susceptible to dust contamination. Dust on VFD hardware can restrict cooling airflow, resulting in diminished performance from heat sinks and circulating fans.

Dust on an electronic device can cause malfunction or even failure. Dust absorbs moisture, which also contributes to failure. Periodically spraying air through the heat sink fan is a good PM measure. Discharging compressed air into a VFD is a viable option in some environments, but typical plant air contains oil and water. For cooling, you must use dry compressed air that is oil-free, or you are likely to do more harm than good. This requires a specialized, dedicated and expensive air supply. And you still run the risk of generating electrostatic discharge (ESD). A non-static generating spray or a reverse-operated ESD vacuum will reduce static build-up. Common plastics are prime generators of static electricity. The material in ESD vacuum cases and fans is a special, non-static-generating plastic. These vacuums, and cans of non-static-generating compressed air, are available through static control equipment companies.

Keep it dry

Figure 2. Moisture caused corrosion.

In Figure 2 you can see what happens to a control board periodically subjected to a moist environment. Initially, this VFD was wall-mounted in a clean, dry area of a mechanical room. However, as is often the case, a well-meaning modification led to problems. An area of the building, close to the mechanical room, required a dehumidifier. Wall space was available above the VFD, so the dehumidifier was placed there. Unfortunately, the VFD was a NEMA 1 enclosure style (side vents with no seal around the cover). Water began dripping from the dehumidifier and into the drive. In six months, the VFD accumulated enough water to produce circuit board corrosion.

What about condensation? Some VFD manufacturers included a type of “condensation protection” on earlier product versions. When the mercury dipped below 32 F, the software logic would not allow the drive to start. VFDs seldom offer this protection today. If you operate the VFD all day every day, the normal radiant heat from the heatsink should prevent condensation. Unless the unit is in continuous operation, use a NEMA 12 enclosure and thermostatically controlled space heater if it’s located where condensation is likely.

Keep connections tight

While this sounds basic, checking connections is a step many people miss or do incorrectly. Heat cycles and mechanical vibration can lead to sub-standard connections, as can standard maintenance practices. Retorquing screws is not a good idea, and further tightening an already tight connection can ruin it. Instead, use an infrared (IR) thermometer to note hot connections, and check their torque before tightening.

Bad connections eventually lead to arcing. At the VFD input, this could result in nuisance overvoltage faults, clearing of input fuses or damage to protective components. At the VFD output, it could result in over-current faults or damage to power components. Figure 3 shows what can happen.

Loose control wiring connections can cause erratic operation. For example, a loose start/stop signal wire can cause uncontrollable VFD stops. A loose speed reference wire can cause drive speed to fluctuate, resulting in scrap, injury or machine damage.

Figure 3. Loose input and output power connections.

Inspection and monitoring

As part of a predictive maintenance (PdM) procedure, don’t overlook internal VFD components. Take voltage measurements while the drive is in operation. Fluctuations in DC bus voltage measurements can indicate bus capacitor degradation. One function of the capacitor bank is to act as a filter section (smoothing out any AC ripple voltage on the bus). Abnormal AC voltage on the DC bus indicates the capacitors are headed for trouble. Most VFD manufacturers have a special terminal block for this type of measurement and for the dynamic braking resistors’ connection. Measurements more than 4V-AC may indicate a capacitor filtering problem or a possible problem with the diode bridge converter section (ahead of the bus). If you have such voltage levels, consult the drive manufacturer before taking further action.

With the drive in START and at zero speed, you should read output voltage of 40V-AC phase-to-phase or less. If you read more than this, you may have transistor leakage. At zero speed, the power components should not be operating. If your readings are 60V-AC or more, you can expect power component failure (see Figure 4).

Figure 4. Capacitor stress problems.

Regularly monitor heat sink temperatures. Most VFDs include a direct temperature readout on the keypad or display. Verify the location of the readout, and make checking it part of a weekly or monthly drive operation review.

What about spare VFDs? Store them in a clean, dry environment. Power them up every six months to keep the DC bus capacitors at their peak performance capability. Otherwise, their charging ability will significantly diminish. A capacitor is much like a battery — it needs to go into service soon after purchase or it will suffer a loss of usable life.

You wouldn’t place your laptop computer outside, on the roof of a building or in direct sunlight, where temperatures could reach 115 F or as low as –10 F. Because a VFD is basically a computer with a power supply, it needs the same consideration. Some VFD manufacturers advertise 200,000 hours — almost 23 years — of mean time between failures. Such impressive performance is easy to obtain, if you follow these simple procedures.

Photos: ABB Inc.