VSD air compressors not all they're cracked up to be

Across America, utilities use energy rebate programs to provide industrial users with incentives to reduce compressed air energy consumption. In the worst case, energy rebate programs merely help compressor manufacturers sell higher-cost, so-called more efficient compressed air equipment. The sales are based on theoretical savings projections or “free audits” a salesperson provides, rather than on the savings realized after the equipment is installed.

This practice, along with users’ misconception that variable-speed-drive compressors always save energy, has led to the overselling of variable-speed drive (VSD) compressors. There are many systems where installing a VSD compressor can actually increase energy costs, so never assume a VSD compressor is the silver bullet that will reduce your compressed air energy costs. In addition, so-called free audits often overstate the savings available from installing a VSD compressor.

For example, a recent Plant Services article (“Unwinding the spin: A critical look at variable-speed-drive air compressors”) stated, “Often, the free audits exaggerate paybacks by including savings the end user can achieve without purchasing a VSD compressor.”

Often the structure of energy rebate programs generates a flurry of activity, which produces many potential projects that forecast millions of dollars in annual energy savings. A later review of these projects often finds that the user never implemented the recommendations, and that a substantial portion of the projects that were implemented provided neither the projected energy reduction nor a sustainable reduction in energy use. There are myriad reasons for these dismal rebate program results, including:

- The rebate program paid for the compressed air system audit or leak survey without requiring a capital investment from the industrial user.

- The rebate program promoted installing test equipment such as orifice meters to measure compressor performance, system demand and leak rates.

- The rebate program offered a rebate for leak repair.

- Rather than basing the rebate on actual savings, the program used the projected savings from theoretical projections or free audits.

- The rebate program didn’t include follow-up to ensure that the user is sustaining the gains.

- The rebate program helped pay for equipment that the user installed into an inefficient system.

- The user didn’t integrate the equipment into the system properly.

- The user didn’t have enough capital to implement the recommendations.

- The energy rate is too low to give the user enough incentive to sustain the savings.

Rebate program administrators often overlook the sustainability of compressed air system improvements, particularly when it comes to reducing the leak rate. Most of the time, lower leak rates are unsustainable and shouldn’t be included in energy rebate programs; however, this isn’t always the case.

For example, a user can argue, and rightfully so, that a lower leak rate is sustainable because the plan is to replace barbed pushlock fittings with compression fittings.

If a utility desires to include air leak surveys and leak repairs in its rebate program, then it should spread the rebate over three years and require annual baselining to ensure that the user is sustaining the lower leak rate.

We find that if the user doesn’t invest cash in the process, there’s little incentive to implement any recommendations. Therefore, users should expect to pay for a compressed air system audit or leak survey. The rebate program should help defray the cost of implementing the recommendations from the compressed air system audit, and only those recommendations that the rebate program administrator deems sustainable. The positive aspect of a rebate program is that it can reduce the simple payback or the capital cost to a level that makes financial sense for the user.

Finally, because anyone can claim to be an auditor, better rebate programs provide you with a list of qualified auditors. In addition, a rebate program administrator should be wary of free audits because some compressor manufacturers have developed black boxes, the only purpose of which is selling equipment. Such devices lack objectivity because their solutions are always equipment-based.

Energy rebate programs that take one of the following approaches will generate long-term energy savings if the rebate program administrator focuses on sustainable improvements.

Based on implementing audit recommendations

It’s beneficial to have a qualified auditor conduct a compressed air system audit because the audit provides both the user and the rebate program administrator with a roadmap to success. If upgrading compressed air equipment can reduce energy costs by 2% to 10%, retrofitting the system can reduce energy costs by 10% to 60%. Therefore, the energy rebate program should focus on the system rather than only on equipment. To capture every opportunity, a compressed air system audit should include an audit of both the supply and demand sides.

The main benefits of a compressed air system audit are the initial baseline data, present and projected demand profiles, an estimated project cost and a projected simple payback. To ensure that the projected savings are sustainable, the rebate program administrator must ensure that the auditor based the projected demand profile on sustainable reductions. Projecting energy savings from an actual demand profile assures both the user and the program administrator that the savings are actually available. The initial baseline allows the rebate program administrator to compare before and after system efficiency and then provide a rebate based on actual savings. An estimated project cost and simple payback provides the user with the information needed to secure project funding.

At a minimum, the rebate program goal should be to retrofit the supply side of the system, which ensures that power and energy will drop when the demand side is improved. In addition, supply-side improvements normally produce sustainable energy savings and are the best way to ensure that equipment operates efficiently. In focusing on supply-side retrofits, the rebate program administrator must realize that changes that address air quality issues rarely offer an energy savings.

Based on reductions in peak kW and kWh

In its simplest form, the goal of any energy rebate program is to reduce the industrial user’s peak kW and the total annual kWh. However, if the program relied solely on these numbers, it would be giving rebates to companies that are going out of business or whose production is moving overseas. Therefore, the rebate program administrator also must verify that the energy reduction is a result of improved efficiency.Based on efficiency improvements

An approach that some claim simplifies a rebate program provides rebates based on efficiency improvements. Today, energy rebate programs based on efficiency improvements rely solely on some form of supply-side efficiency. The problem with basing a rebate program on supply-side efficiency is that, in most cases, it deteriorates when you repair leaks or make other demand-side improvements. For example, the best supply-side efficiency occurs when all of the compressors are operating at maximum efficiency. As you make demand-side improvements, demand decreases, and the trim compressor begins operating below its maximum efficiency. So, while the peak kW and total kilowatt-hours consumed decreases, the supply-side efficiency deteriorates. Therefore, we must ask, “Is there a better measure for the rebate program administrator to use?” The answer to this question emerges when one looks at the three measures of compressed air system efficiency. Those efficiencies are:- Supply-side efficiency (input kW per 100 scfm output).

- Demand-side efficiency (SCF per unit of production).

- System efficiency (average input kW per unit of production).

Supply-side efficiency is equal to the sum of the average input kW of all the compressors and dryers during a specified time period, divided by the average scfm produced during the same period divided by 100. Supply-side efficiency reflects changes made on the supply side of the system, such as eliminating open drainage, automating the compressors, installing more efficient compressors and dryers, and repairing supply-side equipment.

Demand-side efficiency is equal to the total volume of air delivered to the system during a specified time period divided by the number of units of production produced during the same period. The SCF delivered to the system is equal to the total volume of compressed air produced in a period minus the volume lost to compressor room leaks and open drainage and dryer purge during the same period. The demand-side efficiency improves as you reduce the leak rate and eliminate artificial demand and inappropriate uses of compressed air.

System efficiency is equal to the sum of the average input kW of all the compressors and dryers during a specified period divided by the number of units of production produced during the same period. System efficiency improves when you improve either the supply or the demand side of the compressed air system.

Demand-side and system performance rates

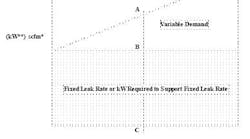

The problem with basing rebates on demand-side or system efficiencies is that these variables are meaningless unless one compares periods with identical production rates. The reason is that plants have a relatively fixed leak rate. We can resolve this problem by using performance rates rather than efficiencies (Figure 1).

First, conduct a low-load test to measure the fixed demand (B) and the kW (B) needed to support it. The fixed demand is the demand that occurs during periods of no production. Knowing fixed demand and the kW that supports it allows you to calculate the demand-side and system performance rates.

For example, the demand-side performance rate is equal to:

((A – B)*(T))/(C)

where T = time (in minutes)

A = the average flow rate (scfm) into the system during T minutes

B = the average fixed demand (scfm)

C = the number of units of production produced during T minutes

The system performance rate is equal to (A – B)/(C)

where A = the average kW during T minutes

B = kW supporting the fixed demand

C = the number of units of production produced during T minutes

The demand-side performance rate will decrease as you eliminate open drainage, artificial demand and inappropriate uses, and repair the leaks. In addition to decreasing along with demand-side improvements, the system performance rate also improves with supply-side improvements such as installing automation or new, more efficient compressors and dryers. Therefore, the system performance rate is the best indicator for a rebate program administrator to use. The supply-side efficiency and the demand-side performance rate determine where the improvements occurred.

Measure your fixed demand rate and its associated kW at least annually and again after each major leak repair effort. If your trim compressor constitutes more than half the online kW, you’d need to compare system performance rates during periods with the same production rates because a trim compressor’s efficiency is a function of its average load.

While it’s true that using a performance rate masks the magnitude of the leak rate, it also provides you with a tool that lets you know whether your efforts are paying off. The value of measuring the fixed demand and tracking efficiency and performance rates lies in the fact that you’ll know where to look for problems. For example, if system performance is deteriorating, look at the supply-side efficiency and the demand-side performance rate to determine on which side the problem lies. If both values have increased, then the problem is most likely caused by an increase in the fixed demand. You can confirm this by conducting a low-load test. Conducting a demand-side survey during the low-load test allows you to separate the fixed demand into production uses and leaks.

Form of the energy rebate

The form of the energy rebate is important to the success of the program. By themselves, compressed air system audits, leak surveys and installing VSD compressors can do little to reduce energy use. The energy rebate program achieves the largest sustainable energy savings when you implement a comprehensive system retrofit with the goal of improving compressed air system efficiency.

In many cases, you’ll need an energy rebate to reduce either capital cost or simple payback to make the project attractive. The energy rebate can achieve this either by reducing project cost or increasing the annual energy savings. In some cases, you face capital spending restrictions and might require a loan to fund the project.

Your main takeaway is this: Any viable compressed air system energy rebate program must move away from simply paying for equipment, compressed air system audits and leak surveys. Instead, it must focus on projects that produce sustainable reductions in the energy that generates the compressed air required for each unit of production.

Chris E. Beals is senior auditor at datacation, LLC, Denver, Colo. Contact him at [email protected] and (303) 771-4839.