DOE boiler software is a hot way to save energy

Fuel prices are prompting plant professionals to consider improving steam system efficiency. The U.S. Department of Energy (DOE), through the Industrial Technologies Program (ITP), instituted the BestPractices program to provide services and information for improving energy use and productivity in areas such as compressed air, motors, process heating and steam. We used one of those tools, the Steam System Assessment Tool (SSAT), to perform a parametric study to quantify energy savings from five common best practices for packaged boiler systems. You can use the link at the end of this article to download the free software and perform plant-specific studies of your own.

We developed a base model to benchmark and analyze the energy savings related to potential system changes. The five best practices investigated were:

- Makeup water temperature

- Steam pressure

- Blowdown rate

- Blowdown heat recovery

- Temperature and quantity of condensate return

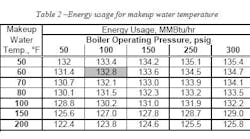

Table 1 shows the SSAT input values for the base model used for the study. Although the base model reflects one specific system, projected energy savings can be applied to more complex systems.

Case 1 - Makeup water temperature

As the temperature of your makeup water increases, the amount of boiler fuel you need to convert it to steam decreases. Makeup water can be preheated using blowdown heat recovery systems and stack economizers. The latter approach is more efficient with continuous and automatic blowdown systems. Heat can be recovered from the water and flash steam in the blowdown. A heat exchanger must be used for recovering the heat content in the water because dissolved solids are present. The preheated water from the exchanger can be sent to the deaerator as part of the makeup water.

To collect energy from the steam portion, dump the blowdown to a flash tank, where a portion of the water will flash to steam. The flashed steam can be used in low-pressure applications such as in the deaerator.

When possible, recover heat from the stack. An economizer efficiently recovers wasted stack heat and transfers it to boiler makeup water or any other fluid. An economizer might reduce fuel usage by 5% to 10% by recovering this waste heat. Condensing economizers require more plant modifications and cost more, but provide higher heat recovery potential than conventional economizers. The condensing economizer recovers not only the sensible heat, but also the latent heat in the flue gases.

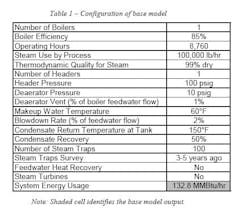

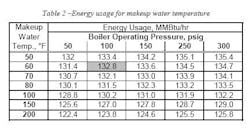

To examine the effect of makeup water temperature on energy consumption, we made multiple runs of the base model while varying the makeup water temperature from 60F to 200F and the header pressure from 50 psig to 300 psig. The energy input requirement corresponding to changes in these variables is shown in Table 2. It shows that increases in makeup water temperature decrease the energy usage from the base case.

Case 2 Steam pressure

As your operating steam pressure increases, so do your system losses in the form of increased steam leaks from piping and through traps as well as convection and radiation losses from system components.

SSAT assumes gross expected steam trap failure and leakage rates based on your interval between maintenance projects. The software considers each failed trap and steam leak as a 1/8-inch and a 1/16-inch orifice, respectively. Thus, as system pressure increases, more energy is lost through leaks and failed traps. Although SSAT accounts for steam losses, it doesnt calculate convection and radiation losses as a function of pressure. In addition, using a greater operating steam pressure requires more fuel consumption.

Like any mechanical device, steam traps fail over time. Perform periodic testing to locate the malfunctioning traps that waste energy, harm production and damage equipment by allowing condensate or air to contaminate the product or decrease the steam temperature.

Detecting defective traps can involve ultrasonic testing, listening to audible trap sounds, checking condensate vents, opening test valves, visually checking using a sight glass, and measuring temperature differences. Install drip legs and steam trap stations:

- At low points in the piping system

- At changes of direction

- Upstream of normally-closed valves

- Downstream of end-use equipment

Steam systems that go three to five years between inspections will suffer 15% to 30% trap failure, according to DOE estimates. Furthermore, DOE recommends that a system operating at a pressure below 30 psig be tested annually for failed traps. Systems operating at a pressure between 30 psig and 150 psig should be tested monthly or quarterly. Systems with higher steam pressure ought to be tested weekly or monthly.

In some cases, larger leaks get neglected for long periods because many think theyre too obvious to be a problem. Steam should not be apparent in a plant, because its discharged to a condensate return system. High-pressure steam leaks are dangerous because they can be invisible to the naked eye.

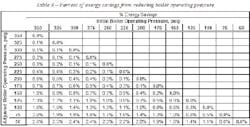

To examine the effect of header pressure on energy consumption, we made multiple runs that varied the header pressure from 50 psig to 350 psig. The results are presented in Table 3.

Case 3 Blowdown rate

Its impossible to have boiler blowdown without losing energy, which is why you should minimize blowdown rates. The duration and frequency of blowdown is a function of the quantity and condition of your boiler makeup water. A typical blowdown rate is between 4% and 8% of the boiler feedwater flow rate.

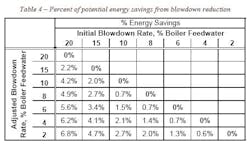

SSAT can calculate the energy savings derived from minimizing blowdown. To assess its effect on energy consumption, we varied blowdown between 2% and 20% of the boiler feedwater flow rate. The energy savings for the entire steam system are presented in Table 4.

Beyond energy savings, though, the blowdown rate has an immediate effect on the makeup rate. As blowdown decreases, less makeup water is needed and less energy is consumed at the deaerator. Furthermore, fewer chemicals are needed to render the makeup water suitable for use. Although our study didnt consider this, you shouldnt neglect it as a source of additional savings.

Case 4 Condensate return

Sending condensate back to the boiler at a higher temperature recovers more of its energy. So does the volume you return. In most cases, condensate can be returned to the boiler at temperatures in excess of 200F, and conditioned water is normally taken to the boiler at temperatures ranging from 50F to 80F. Consequently, the energy in the condensate can be more than 10% of the total energy content in a typical system.

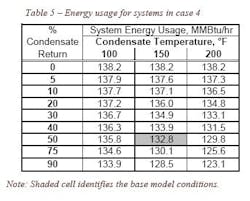

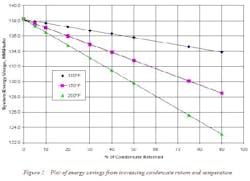

Our base model was assumed to return 50% of the steam at 150F. The rest was assumed to be lost. Multiple runs varied the amount of condensate returned from 0% to 90% and its temperature from 100F to 200F. The energy usage for each run is tabulated in Table 5 and Figure 1.

Less energy is used as condensate quantity and temperature increase because less makeup water, which is colder than condensate, is needed. Therefore, youll burn less energy heating the same volume of water to the desired temperature because the returned condensate has greater energy content.

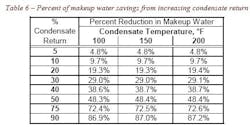

Table 6 illustrates the makeup water reduction from the simulations performed in Case 4. Note that an increase in the volume of condensate returned doesnt produce a proportionate savings in makeup water because some makeup water is needed for fixed losses such as leaks and deaerator venting.

However, as the condensate temperature increases, the difference between the percent of condensate return and percent of makeup water decreases slightly. The reason is the reduction in the volume of blowdown and the steam injection in the deaerator, which reduces feedwater flow. As the amount of condensate retuned increases, theres less makeup water required. Because makeup water is the source of system impurities, a reduction in makeup water reduces the amount of blowdown required.

The DOE Steam System Assessment Tool is a valuable resource for finding the potential energy savings associated with a number of energy-related best practices. Its fast and relatively easy-to-use software that you should try. It wont substitute for detailed engineering studies, but its helpful for prioritizing candidate energy projects.

Although our investigation considered only four items, SSAT is capable of more analyses, including evaluating additional boiler variables, heat recovery applications, and combined heat and power systems.

Youll find more DOE resources at the Industrial Technologies Program, BestPractices (www.oit.doe.gov/bestpractices). The software downloads are at www1.eere.energy.gov/industry/bestpractices/software.html.

Alexandre Kisslinger Rodrigues is Industrial Specialist at the Center for Industrial Research and Service Iowa State University in Ames, Iowa. Contact him at [email protected] and (515) 294-1588.

Gregory M. Maxwell is TITLE in the Mechanical Engineering Department, Iowa State University, Iowa State University in Ames, Iowa. Contact him at [email protected] and PHONE.

References:

U.S. Department of Energy, Steam Tip Sheet Number 3: Use Feedwater Economizers for Waste Heat Recovery, June 1999.

Paffel, K., Personal contacts.

U.S. Department of Energy, Steam Tip Sheet Number 1: Inspect and Repair Steam Traps, June 1999.

U.S. Department of Energy, Steam Tip Sheet Number 9: Minimize Boiler Blowdown, June 2001.

U.S. Department of Energy, Steam Tip Sheet Number 8: Return Condensate to the Boiler, June 2001.

Additional resources:

ASHRAE, Equipment Handbook, 1988.

ASME B31.1-2001, Power Piping code.

DeHart, R.M., Improving Boiler Performance Through Operator Training, Energy Engineering: Journal of the Association of Energy Engineering, vol. 92, 1995.

Frankel, M., Facility Piping Systems Handbook, McGraw Hill, 2nd ed., 2002.

Hadley, S.W., Potential for Energy Efficiency in the State of Iowa, Oak Ridge National Laboratory, June 2001.

Moran, M.J. and Shapiro, H.N., Fundamentals of Engineering Thermodynamics, John Willey & Sons, 4th ed., 1999.

Mull, T. E., Practical Guide to Energy Management for Facilities Engineers and Managers, ASME, NY, 2001.

Nebraska Boiler, Boiler Book Control Guidelines, 2003.

Singh, R.P. and Heldman, D.R., Introduction to Food Engineering, Academic Press, 3rd ed., 2001.

Spirax Sarco, Spirax Sarco Learning Centre, www.spiraxsarco.com/learn

Taplin, H.R., Reducing Energy Costs of Boilers, Energy Engineering: Journal of the Association of Energy Engineering, vol. 92, 1995.

U.S. Department of Commerce: Bureau of Economic Analysis Regional Accounts. www.bea.doc.gov/bea/regional/gsp/

U.S. Department of Energy, Improving Steam System Performance: A Sourcebook for Industry, June 2002.

U.S. Department of Energy, Steam Tip Sheets, www1.eere.energy.gov/industry/bestpractices/tip_sheets_steam.html

Voyce, B., Iowa Workforce Development Employment Statistics Bureau, Seasonally Adjusted Nonfarm Employment, August 2004.

Wulfinghoff, D. R., Energy Efficiency Manual, Energy Institute, MD, 1999.