Compressed air isnt free. Youd think that would be obvious to maintenance and operations personnel in plants where some of the largest motors are harnessed to compressors, howling and yammering away 24/7, sucking up, in many cases, the largest percentage of an increasingly outrageous utility bill. Wasting upwards of 30% of that energy should probably be illegal, but its not, and apparently most folks are oblivious.

If water or oil are leaking, you know it, says Len Bishop, manager, Draw Professional Services (www.drawproservices.com). If gas is leaking, you smell it. You can see steam. But compressed air? Its not a safety issue until someone complains that its too loud. So unless its knocking your hat off, you ignore it.

Statistics from the Compressed Air Challenge (CAC) and DOE are confirmed by the compressed air system experts: The average facility has 30% to 35% leakage if it hasnt taken any recent action. And a survey by the Office of Industrial Technologies says 57% of facilities have taken no action during the past two years.

Air is a clear fluid that doesnt make a mess, says David Booth, system specialist, Sullair (www.sullair.com). It can leak forever and not directly affect anything but cost. So, unfortunately, leaks are a big component that no one is willing to fix permanently.

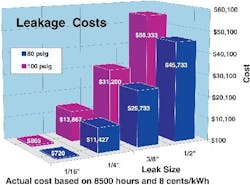

Even a 1/16 inch diameter leak can cost big bucks (Figure 1). But you neednt get out a caliper. If you can hear it without an ultrasonic leak detector, its at least 8 cfm to 10 cfm at $300 per year per cfm, says Bishop. It may not be a safety issue, but its costing you money.

The excess cost goes beyond wasted energy. Leaks lead to other plant problems:

- Fluctuating system pressure: Inconsistent or faulty performance of air tools and other air-operated and powered equipment.

- Excess compressor capacity: higher than necessary equipment and maintenance costs. Not only are you wasting energy, youre likely to be mismatching the compressor, says John Bartos, vice president of engineering and new product development, Cooper Compression (www.coopercameron.com). You buy based on calculated demand, and leaks can really affect the actual performance.

- Excess load on supply equipment: Increased maintenance costs, decreased service life.

- Thwarting other system efficiency efforts: Its impossible to optimize system pressure and compressor control schemes with excessive leaks. In cases where the total leak load exceeds 10%, the artificial demand created by leaks must be addressed in order to obtain an accurate air demand profile for the plant, says Wayne Perry, technical director, Kaeser Compressors (www.kaeser.com). Only then can other recommendations and improvements take place.

- Wet air: While letting air out, leaks let moisture in. Valves on drain legs are left cracked open because too much water is coming into the equipment, says Scott Stroup, president, Airometrix Manufacturing (www.airometrix.com). But unless the air dryer is malfunctioning, the air is leaving it at a -40 degree dewpoint. Wheres the water coming from? It comes in at the air leaks.

Its counterintuitive, but Ficks Law explains why water migrates from high-humidity outside air into dry compressed air even though air is coming out the leak. Its hard and for some people, impossible to believe, but its true, Stroup says. Is your water problem bigger when the humidity is high or its raining? Thats why.

So with all these potential benefits, why is it that, as Jan Zuercher, director, air systems, Quincy Compressor (www.quincycompressor.com), says, Most people do very little leak management a majority do it infrequently or not at all.

Some plants are ignorant, more feel they cant devote time and effort to leak management, and plenty see it as pointless: fixing some leaks makes the others leak more, and youre back to zero (see sidebar, Exercise in futility?). But understanding where most leaks occur, efficient ways to detect them, and their effects on system pressure and performance can help you implement an energy-saving leak management program thats simple, efficient, rewarding and, dare we say, almost fun.

Modus operandi

Before you start shopping for leak detection equipment or get bogged down seeking management support, its helpful to know where many of the largest leaks are likely to be found (Table 1). Drawing on his extensive experience, Stroup provides this ranking:

|

- Hoses and hose fittings: On hoses, the fitting-to-hose connections are most likely due to improper clamping or working loose. Next comes the hose itself, cut or gashed, Stroup says, then the quick-disconnects.

- Pressure regulators and filter/regulator/lubricators (FRLs): The stems on the filter bowls leak or are left open, O-rings leak at the bowl-to-housing connection, filter bowls are cracked, and on the regulators themselves, O-rings, gaskets and the piping connections between elements often leak.

- Plastic tubing: There are so many of them, the sheer number adds up, Stroup says. The leaks are mainly at push-to-connect fittings.Zuercher agrees that tubing connectors are a common cause of leaks, but says, Theyre typically too small to be worth repairing. Fix the largest leaks first to get the biggest bang for the buck.

- Header and distribution piping: Welded steel and soldered copper pipe are generally pretty tight, Stroup says. Threaded pipe is more likely to leak.

- Leaks within equipment: In some plants, these are a major concern. A small hole there can go undetected and cause a pressure drop that leads to an equipment malfunction, says Stroup. People end up replacing a cylinder or solenoid valve trying to fix an intermittent equipment problem thats actually caused by an undetected leak.

For example, a packaging machine wouldnt work properly when other equipment in the area was running. Mechanics replaced a solenoid valve with no effect. When we got next to it, we could hear a leak, Stroup says. We crawled under it and found where a chain had worn a hole in an air line. Fixing that fixed the problem with the machine.

Pneumatic systems inside panels often share a common, ducted exhaust, masking the presence of leaks in the normal airflow. An internal failure of a solenoid valve can blow a lot of undetected air, whether the machines running or not. We also often find missing faceplates and uncapped lines in solenoid cabinets, Stroup adds.

Dont ignore useful leaks. For example, compressed air used to position paper in an envelope machine should be turned off when the machines not running. Add a shut-off valve interlocked with the on-off switch on the machine. A manual valve isnt reliable because operators dont want to worry about it and will simply leave it on.

Get on the case

Detection methods range in sophistication from listening and running hands over pipes and equipment to soap bubbles and, todays big gun, the ultrasonic leak detector (ULD). All these tools have their place, but the most effective and least familiar is the ULD.

Ultrasonic is a critical element, says Zuercher. The old-school thinking was that you had to detect leaks on nights and weekends when the plant is quiet so you can hear the leaks, and most people dont want to do that. With ultrasound, you can detect leaks during normal production.

A running plant is more likely to reveal critical leaks. Leak detection can and should be performed during the normal course of production for maximum effectiveness, says Perry.

Handheld ULDs locate leaks both in compressed air and vacuum systems, and search areas such as valve seats, drain traps, tanks and piping. USDs can detect internal leaks and leaks that are near the ceiling, outdoors or in noisy environments. For example, a blown diaphragm on a valve in a baghouse can leak a lot of air where it is easily overlooked, Zuercher says. Good ultrasonic can detect leaks from over 50 feet away.

And compared to the other methods, Stroup points out, You can move much faster with ultrasonic.

While a good ULD can find leaks quickly, aficionados disagree on whether they can be used to judge leak rate. Zuercher says the size of a leak is proportional to the volume of the sound given off by the ultrasonic leak detector, but Ben Fried, product development and support, CTRL Systems (www.ctrlsys.com), says, The number-one misconception about ULDs is that they can measure the intensity of a leak and correlate it to dollars lost. This is 100% false.

Many factors change the intensity of a leak, including pressure; temperature; humidity; distance from the receiver; size, shape and location of the hole; proximity of hole to other objects; battery power of receiver; etc., Fried says. There is no way to determine amount of cfm loss based on a decibel reading or some other relative measurement.

In general, ULD capabilities vary, and experts have strong words about making sure the one you buy will do what you expect (see sidebar, Pick one out of the lineup).

Those same experts agree that, although the learning curve is short, some training is required. Get a demo, says Zuercher. Have someone come in and show you how they work.

If at least one person can go through the training, they can teach others. The basics are very simple, says Stroup. One of his brewery clients now has 15 or 20 instruments. The predictive maintenance specialist is the plants champion, Stoup says. He has been through two or three levels of training, and he can train the others in an hour and a half.

Airometrix Manufacturing runs training classes focused on operation and maintenance of compressed air systems. The eight-hour day includes 1-1/2 to 2 hours on leaks. Stroup says, UE Systems also offers training to go with their instruments.

Though not yet a common use, increasingly sophisticated infrared imagers can detect the thermal plume of a compressed air or gas leak. We have used this technique in the past for pinpointing leaks on certain pieces of equipment, especially when it is in an environment where you cannot enter safely, says Stroup.

Finally, high-tech detection methods are powerful, but dont overlook the advantages of enlisting your significant number of operators and floor supervisors to detect leaks (see sidebar, Start a neighborhood watch).

Stop repeat offenders

Vigilance is your best defense against a growing leak population, but a few key practices can help. First, set aside the Teflon tape when assembling threaded pipe and fittings. Teflon tape seals the contact points, but it doesnt fill the voids, says Tom Buckley, application engineer, Henkel Corp. (www.loctite.com). Theres a lot of space left for leak paths. Sealants in the form of thick liquids or pastes fully fill the spaces in the threads.

On compressors, our extensive testing shows Teflon tape is not an answer, says Booth. You need a quality sealant compatible with the compressor fluid.

Before the sealant has cured, pipe threads can be adjusted for alignment by loosening or tightening without compromising the seal. Sealants that wont cure while exposed to air can be applied to all the pipes and fittings in one operation before assembly to save time and effort. Fittings can be adjusted for several hours after assembly and once cured, the sealant adds mechanical strength and vibration resistance to the joint.

Beware hardening sealants. Conventional pipe dopes and high-strength sealants can make joints difficult or impossible to disassemble. You want a low-strength cure, Buckley says.

Sealant chemical resistance is rarely an issue. In an air-tight joint, With four or five threads in contact, fluid cant really get to the sealant, Buckley says. A small amount of compressor fluid is going to go down the pipe, not penetrate the cured sealant.

Fluid compatibility is a bigger issue with the elastomers in FRLs, non-threaded pipe joints and connected equipment. The diester lubricants can be extremely aggressive, Booth says. If youre using a diester, be sure youre using the correct elastomers and hoses.

Though piping ranks low on the frequency list, leaks there can be the most difficult to repair. Joints and fittings can loosen or wear over time and should be routinely checked through a reliable method, says Perry. Old or outdated piping of any material should be immediately replaced.

While many prefer copper and stainless steel, there are several modular aluminum piping products that offer a cost-effective alternative. Not only can these products be fully integrated into existing systems, they offer push-to-fit connections that eliminate the human error factor in brazing and welding joints and fittings the most likely place piping leaks occur, Perry adds.

If a leaky section of pipe is in a hazardous area, requires an outside contractor to repair, or would cause significant downtime to repair due to interrupted compressed air supply, it may make sense to replace it using a modular system. Aluminum and plastic systems are lightweight and can be installed quickly without specialized skills. Typical of the genre, Our push-to-connect system uses high-nitrile seals and is rated to 232 psi, says Tim Deal, manager of customer service and sales, Legris Transair (www.transair.legris.com). The seal material is the same that is commonly used in compressors so it will resist all compressor fluids. Its a good way to replace steel or copper so it doesnt corrode and it doesnt leak again.

Make a major crackdown

Quantifying and systematically controlling compressed air leakage starts and ends with periodically evaluating your systems leak rate (Table II), preferably as a percentage of use. Today, most plants are at 30% to 40%, and Ive been in several that were at 50% or more, says Stroud. The worst tend to be smaller plants that dont think they have money to waste on fixing leaks. They just dont understand.

The best way to determine energy use and savings is to measure electricity consumption of compressors. The Compressed Air Challenge (CAC, www.compressedairchallenge.org) offers two other methods to baseline and evaluate system leakage:

|

To estimate leakage as a percent of compressor capacity lost on a system with start/stop controls, with all air-operated equipment turned off, take several measurements of the load/unload time intervals:

Leakage % = (T x 100)/(T + t)

Where T = on-load time (minutes)

t = off-load time (minutes)

To estimate leakage in cfm on a system with other controls, first estimate the volume of the system including downstream air receivers, air mains and piping. Then, using a pressure gauge downstream of the primary receiver, record the system pressure, shut the air off at the primary receiver outlet and measure the time it takes for the pressure to drop (ΔP) to a value approximately one-half the initial system pressure:

Leakage (cfm free air) = (V x ΔP)/T x 14.7) x 1.25

Where V = system volume in cubic feet

ΔP is in psig

T is in minutes

(The 1.25 multiplier corrects leakage to normal system pressure.)

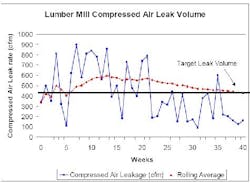

Once you know where you are, you can estimate potential savings and measure progress over time. No one is going to get to zero leaks, Stroud says, but even in heavy industry with inaccessible equipment, you should be able to achieve 15% or less. Cleaner facilities should reach 10% and the best are at about 5%, though I know of two that made it to 3%.

The inspirational dollar amounts shown in Figure 1 arent very useful for estimating real-life potential savings, as typical leaks are not perfect orifices at constant, known pressure. We test air systems and meter the flow volumes to quantify the leaks, says Stroup. When we do that at different pressures, we dont see a one-to-one correlation.

For example, he says, the charts will show a 1/4-inch hole at 100 psig leaks 104 cfm and costs about $10,000 per year, but thats based on a perfect orifice. A real leak is generally a gash or cut or other irregular shape, so you use a 1/4-inch equivalent area, but you cant put 104 cfm through the tube, so you have to take it with a grain of salt, Stroup says. I usually cut it in half for a more realistic estimate.

Ready to find and fix leaks? First, prioritize. Start in the area where the most air is used or where the most leaks are. Stroup says, Most plants have a feel for that.

Finding and fixing leaks should progress from gross to fine. The first time through, focus on 20 cfm leaks and ignore 1 cfm leaks. Start with your ears and hands, then get to ultrasonic, Stroup says. You cant quantify a leak with ultrasonic or any other method, but you can estimate.

Stroup says, initially, a large leak is more than 10 cfm, medium is 5 cfm to 10 cfm, and small is less than 5 cfm. Do the large leaks first, and the medium ones if you can, he says. Next time around, the medium leaks will be large -- reclassify them and do it over. Eventually the leaks will be too small to be worth fixing. Then watch them and fix the ones that grow.

Dont be daunted by the results of your first survey. You do a survey and three days later, you have 150 tags, says Bishop, You gag on it. The answer, he says, is dont try to do it all at once do it one day a month. After a year, issue five open work orders a week from your CMMS to find and fix a leak and dont come back until its fixed.

Repeat the survey at regular intervals. In a high-vibration and shock facility like a sawmill, check for leaks monthly, Stroup says. In most facilities, such as food and light manufacturing with stationary machines, quarterly is good. Clean, quiet industries like pharmaceuticals can go semi-annual, but, he warns, Nobody should go longer than six months.

The key is to keep at it. The benefits dont come in one month. Youll fix the leaks, then fix more, Stroup says. For most plants it takes six months to a year to see benefits. And use documentation if it isnt documented, it wont last. The progress of a typical facility is shown in Figure 2.

Machines move, things loosen up its continual, says Bishop. A $20 hose leaks $2,000 a year, and people patch it with duct tape. Dont patch fix. Its a mindset, and you have to buy in.

Implement a regular leak maintenance program. Ultrasonic, feel, listen, whatever youve got, says Bartos. The important thing is to do it regularly. You spend so much money on a compressor and energy, its going to pay off.

Exercise in futility?

Everybody knows they have leaks and most have a lot of them, says Jan Zuercher, director, air systems, Quincy Compressor (www.quincycompressor.com). Its a bit of a vicious circle. As you fix leaks, pressure rises and the remaining leaks leak more. A lot of plants reach the point where they say, Whats the use? Most maintenance staffs are running very lean. Theyre focused on keeping the plant running. Who has the time?

Its true that most calculations of potential savings from leak repairs are optimistic, and for two reasons:

- Estimates assume that the system is 100% efficient: saved cfm are converted directly to less horsepower consumed in the compressor room. In reality, this is never the case, and its usually not even close, says Robert Horneman, marketing manager, Industrial Air Solutions, Ingersoll Rand Industrial Technologies (www.irco.com).

For example, reducing the air load on a modulating compressor will cause the inlet valve to close more, drawing a vacuum under the valve. A modulating machine at 70% load will still pull 93% of its full-load horsepower, Horneman says. Similarly a centrifugal compressor can only back down so far depending on its surge points before it starts to blow off. If it's close to its surge point and you fix leaks, it will simply blow off air and you have gained nothing. You need a good handle on the air system as a whole and how each part affects it, especially how the system reacts to part loading. - Estimates assume that fixing a leak has no effect on the rest of the system. In practice, fixing a leak often causes pressure to rise in the vicinity of the repair. This may not be all bad according to Scott Stroup, Scott Stroup, president, Airometrix Manufacturing (www.airometrix.com), Most of our customers would do back-flips for five more psi.

But higher pressure means an exponential increase in flow through unregulated uses, including leaks. This will very quickly return the leak load to original levels, Horneman says.

The solution is to tightly control the demand pressure so the decrease in leak load will not increase the local pressure, and to control the compressor output so the decreased demand will be reflected in online horsepower. Pressure can be controlled with an expander valve between supply and demand.

This allows you to fix leaks without affecting the rest of the system by holding pressure within two psi, says Horneman. This valve can react to dynamic demand changes quicker than the compressor controls, allowing the system to respond to events with stored compressed air rather than compressor horsepower.

I am not advocating throwing a piece of machinery into any system for a resolution, Horneman says.

Compressed air systems are unique and components must be understood in their relation to the whole before an effective solution can be identified. A detailed analysis of the system is essential to avoid improper allocation of capital.

ULD: Pick from a lineup

Ben Fried, product development and support, CTRL Systems (www.ctrlsys.com) offers these suggestions for choosing an ultrasonic leak detector (ULD):

- Sensitivity: Several ultrasonic leak detectors (ULDs) on the market offer a wide range of sensitivity. Rule of thumb: You get what you pay for.

- Selectivity: This relates to dynamic range of a ULD. Some detectors have wide bandwidth, thereby picking up more white noise or static. Additional noise decreases the user's ability to detect a leak.

- Volume: Some ULDs feature adjustable sensitivity and volume. Changing the volume increases the output amplitude, but doesnt improve sensitivity.

- Price: ULDs range in price from $100 to $10,000. Generally, higher-price ULDs are capable of doing condition monitoring as well. The lowest-priced ULDs arent very effective in a manufacturing facility and can miss most leaks. Ultrasonic leak detector quality is all over the map, adds Jan Zuercher, director, air systems, Quincy Compressor (www.quincycompressor.com). Using one of the units approved for his distributors, I can find a leak that others walk right by. Someone wanting to purchase a leak detector should talk to an experienced user or test a handful of different instruments in their plant.

Start a neighborhood watch

Experts have observed a number of effective practices that can help you enlist operations and more easily implement an effective leak management program:

- Be ready to fix as you go: Carry a wrench when you look for leaks. A lot of them can be repaired on the spot.

- Tag leaks with a three-part tag: Bring in one stub to make a work order. Bring in the second stub when the leak is fixed. Have the repair checked, then bring in the rest of the tag. Leaks can be hard to fix or come back right away, says David Booth, system specialist, Sullair (www.sullair.com). Use a three-part tag find, fix, verify and have someone check the repair and bring in the tag before you say its done.

- Enlist management: One guy takes a camera out in the plant, gets pictures, brings them into management meetings and shows them, This is a $500 problem, says Booth. Hes taken pictures of leaks with two and three leak ID tags that havent been repaired. Until he did this, no one took him seriously.

- Educate operators and get their buy-in: Otherwise, people will stand at a machine for years with air blowing on their knees, Stroup says. Theyre already wearing earplugs so they arent even bothered by the noise. But if you approach their machine with an ultrasonic instrument and tell them what youre doing, theyll point out the leaks for you.

Like safety, everyone can be aware of the cost of air leaks and be on the lookout. The day after you do a survey, you can get a large leak, says Jan Zuercher, director, air systems, Quincy Compressor (www.quincycompressor.com). If the employees care and report those leaks, it can be a good part of the program. Management can provide incentives.

One plant decided to share the profit. They pay operators $5 apiece for identifying leaks, says Booth. It pays off. Your operators can be the worlds largest detection force.

- See which equipment holds up: Depending on operating conditions, there can be a lot of variation in different types and brands of regulators, FRLs, quick-disconnects, etc. Toss the ones you replace in a bucket, fill it up and look at them. Quit buying stuff that doesnt survive. One client picked the best quick-disconnect and replaced 10,000 all at the same time that is an automotive plant with 3,200 employees, all using hand tools, says Scott Stroup, president, Airometrix Manufacturing (www.airometrix.com). They did it three years ago and it paid off.

- Use a trade-in system: One plant uses a two-barrel trade-in system near the machines on the plant floor to replace leaking hose assemblies. Operators can quickly and easily eliminate a leak by tossing a leaky assembly into a red barrel and taking a refurbished one from a green barrel. It saves a fortune in air and maintenance labor, Stroup says.

- Add a leak survey to your compressor maintenance contract: If it makes sense, divide the plant into quarters and survey one quarter with each visit, Booth says.

- Keep everyone aware: Like a safety program, hang signs such as, 1/4-inch leak = $8,000 per year.