Why be concerned about efficiency if a pump is supplying the necessary flow to maintain plant operations? Many pumps perform well enough for the systems and processes where they are installed, but they may not be the most efficient pumps for the assigned tasks. Inefficient pumps can increase maintenance as well as energy costs.

With the continued pressure to reduce costs for maintenance, plant operations and system downtime, it becomes imperative that we operate in the most efficient and reliable mode possible. Recent studies indicate that pumping systems account for about 20% of the worlds electrical energy demands. In some facilities, the electricity consumed by pumping systems ranges from 25% to 50% of the total electrical energy required for plant operations. Choosing the appropriate pump designs, sizing them properly to the loads, and monitoring their health can improve reliability, as well as materially reduce energy costs.

Whether for initial installation, repair or replacement, the life-cycle cost must be taken into consideration. Life-cycle cost is the cost of the pump during its operational life expectancy. Most life-cycle cost calculations show that the major expenses of a pump over its life span are energy consumed and maintenance of the unit. Overall, energy and maintenance account for roughly 75% of the life-cycle cost.

So, to maximize pump efficiency, two areas must be explored. The first is pump operation: looking at the pump itself and determining its operational efficiency and application within a system or process. The second is how to maintain the pump and systems operating at peak efficiency.

Divine design

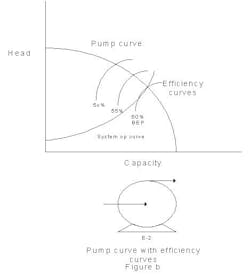

To select the right pump, the design engineer determines the operating parameters needed for the system or process and the type and capacity of the pump needed to satisfy those requirements. The selected pump will be either a roto-dynamic or positive-displacement type based on the system characteristics (Figure a).

PD or not PD

A dynamic pump, typically a centrifugal pump, will be used in applications where a continuous, steady flow of fluid is required. The positive-displacement type will be used for applications where a specific capacity or quantity of fluid is required.

To select the exact pump, you must match the pump operating characteristics with the system operating requirements. There are three basic steps to the selection process. The first is to obtain the pump performance curves for several pumps that meet the operating parameters. The second step is to determine the system resistance coefficient curve and graph it. The third is to superimpose the system resistance coefficient curve onto the pump performance curves of several pumps. The point at which these two curves intersect is the system operating point. The correct pump is the one that has a best efficiency point (BEP) nearest the system operating point. With this information, we should be able to select the most efficient pump for the application every time (Figure b).

Select for efficiency

Pump efficiency (η) is a ratio of hydraulic power to brake horsepower. Hydraulic power (Po) is the power delivered to the fluid by the pump, and brake horsepower (Bhp) is the power required to drive the pump. The equation for determining pump efficiency η = Po/Bhp.

The BEP is the most efficient operating point for your pump. The pump manufacturer uses a test stand to derive this data with pump performance curves, so the as-built efficiency, hydraulic power and brake horsepower may be obtained from the manufacturer.

Normally, the pump is designed to operate at a fixed speed. The head and capacity of the pump is then plotted for this speed. Pump performance curves depict, for a given pump speed, the relationship between required capacity and the pump efficiency, horsepower required, net positive suction head (NPSH) required (NPSH), and total head developed by the pump.

Pump efficiency can involve additional parameters that must be considered during selection. Depending on the application, you may have to evaluate its thermal efficiency and volumetric efficiency. Other system requirements and the operational environment must also be considered.

Beware pump enlargement

Bigger is not always better, but surveys indicate a majority of pumping systems have oversized pumps installed. Oversized pumps are robbing you of operation and maintenance dollars, so why are they there?

Many pumps are oversized because everyone included in the selection process decides to add his own safety factor. For example, the design engineer determines the required flow as 200 gpm, but adds an extra 5% (210 gpm) to this capacity to cover any calculation inconsistency. The plant owner adds another 10% (231 gpm rounds up to 235 gpm) as a safety factor. You send the specification to the pump supplier, who wants to be sure he sends you a pump with sufficient capacity. He informs you he does not have a stock pump for this flow rate and recommends a stock 250 gpm pump, saying that by using this pump you will not incur the additional expense and delay of modifying a pump to supply a flow rate of 235 gpm. You now have a pump that is 25% larger than needed by the original design.

In other cases, you use the pump you have in inventory, or the system requirements have changed but the pump has not. Or you want to cover the possibility of continued growth and eventual need to increase the capacity of the system, so you upsize the pump.

Lets determine the cost of running this oversize pump. Consider a system that uses a centrifugal pump with an electric motor. We will ignore the costs associated with purchase and installation, and focus on the energy cost over one year. For this determination, we assume the pump will operate about 6,000 hours per year, and the average cost per kilowatt-hour is $0.06. We focus on the pump and assume the same electric motor is used to achieve the same efficiency rating.

The hydraulic energy consumption rate in kilowatts = head (ft) x capacity (gpm)/5,308. The head and pump efficiency for different pumps may be obtained from their pump curves and compared (Figure 3). Calculating the kilowatt requirements for each pump and dividing by the efficiency determines the kilowatts used to operate each pump.

For the properly sized 200 gpm pump, the energy required is 150 x 200 / 5,308 = 5.65 kw. From the figure, the pump is 60% efficient, so the power required to operate the pump is 5.65 kw / 0.60 = 9.41 kw.

With an oversized pump, the discharge has to be throttled to obtain the desired flow rate of 200 gpm. This throttling action will result in a corresponding increase in the pump head and the energy required is 250 x 200 / 5,308 = 9.42 kw. From the figure, the pump is only 50% efficient, so the power required to operated the pump is 9.42 kw / 0.50 = 18.84 kw.

During the course of a years operation (6,000 hours), the difference in kilowatt-hour consumption is 18.84 kw x 6,000 hrs vs. 9.41 kw x 6,000 hrs, or 56,580 kwh. At $0.06 per kilowatt-hour, electricity to operate the oversized pump costs $3,394 more than for the properly sized pump, or more than double the energy cost.

The additional energy needed to operate the oversize pump is significant. There are several possible ways to reduce this operations cost, and each one must be evaluated fully to determine if a change would be of benefit to your application. Here is a short list, by no means all-inclusive, of actions that may reduce energy cost:

- Replace the pump

- Install a two-speed motor

- Add a variable-speed drive

- Modify the pump impeller

Maintenance efficiency

In addition to the energy cost, the oversized pump will probably cost more to maintain. Because it is oversized, the pump must be throttled to supply the proper flow. Throttling the flow will result in the pump operating at higher discharge pressure, which can increase maintenance costs due to:

- Erosion

- Wear: wearing rings, packing, mechanical seals by additional torque requirements

- Alignment

- Vibration

- Noise

As-installed pump efficiency is a key indicator of the need for pump maintenance prior to pump failure. We can use pump efficiency to help predict the degradation of the pump and also its effect on the pumping systems operation.

Keep in mind that the manufacturers performance data is based on shop testing of the pump. If the plant application differs from the manufacturers test stand in piping configuration or prime mover, those differences must be taken into consideration. The installed efficiency might differ significantly from the as-built efficiency. The as-installed pump efficiency should be measured upon installation and used as a reference.

The three key parameters to determine as-installed performance and efficiency are pump capacity, head and speed. These parameters can be easily measured in the field and used to determine the pump efficiency using the equation Po = TDH x GPM / 3,960, where GPM is gallons per minute, TDH is total discharge head (measured in feet), and Po is hydraulic power, or the amount of horsepower the pump is generating.

We all know that achieving 100% efficiency is impossible, but we need to get as close to this point as we can to maximize our plants performance. There are many ways to maintain peak efficiency of your pumps and system. Ill mention two things I consider to be important outside the selection of the proper pump during the design process.

The first thing is having a well-trained operational and maintenance staff that works together to maintain equipment in the best possible operational condition. The person who is responsible for the daily operation of a pump or system should be familiar with its normal parameters. The operator is there daily, whereas many maintenance personnel do not have the opportunity to observe the pump systems on a daily basis. Therefore, if an operator has the capability to determine something is not right and conveys this to the maintenance staff, you have a better chance of detecting a problem before it leads to a catastrophic failure and major plant downtime.

Specifically, the operator should be familiar with:

- Pump suction and discharge pressures: These pressures are an indicator of pump performance.

- Allowed leak-off for the mechanical seal or packing: Leak-off is required to seal, cool and lubricate the pump shaft.

- Normal operational noises: Abnormal noise may indicate cavitation, improper alignment and/or bearing failure.

- Thermal characteristics: High temperatures may indicate improper alignment, insufficient cooling and/or excessive throttling.

In one example, a boiler plant operator prevented the failure of a boiler water feed pump. Maintenance had been performed to replace the pump packing. During initial startup of the pump after maintenance, the operator noted that the pump was slower than normal coming up to full speed.

He observed normal operational pressure. He then conducted his routine check of the pump, at which time he identified that there was almost no packing leak-off and the gland was extremely hot to the touch (much hotter than normal). He advised his supervisor of the condition and the pump was secured.

Investigation revealed that the wrong packing had been installed in the pump. If the operator had not been familiar with the pumps operating characteristics, significant damage could have occurred: if allowed to operate unchecked, the heat generated due to the lack of packing leak-off would have damaged the pump shaft and prime mover.

Plant operational capacity was reduced while the packing was again replaced. Packing replacement occurred during a single shift. If the pump had not been secured, the additional maintenance required would have taken a minimum of one week to complete.

The second consideration (along with a well-trained staff) is an efficient maintenance program. The maintenance program I prefer is a reliability-centered program. This program combines the best aspects of the preventive and predictive maintenance programs. I would avoid a reactive maintenance program, if possible, because this program does not allow for proper planning of the maintenance task.

Whichever maintenance program you select for your particular plant, your maintenance personnel must have the proper tools and supplies to complete all repairs. Keep in mind that many manufacturers have gone to a just-in-time inventory control, zero-stock inventory system. This means early identification and planning of a maintenance task is essential. Many items that once were available off the shelf may have a lead-time upward of eight weeks. Whichever program you select, remember that the best maintenance program is useless if it is not followed.

Contact Kenneth P. Gray, project manager, Life Cycle Engineering, at [email protected] or (843) 744-7110.