Ten years after: How the industry has changed before our eyes

During a family dinnertime late last year, my 12 year old suddenly turned to the rest of us and asked, “What’s your favorite movie??” as if his life depended on it.

My wife went first, thinking about it for a few moments before naming West Side Story. (She and I both know it’s really The Warriors, but that’s a different column.) Our 10 year old twins hemmed and hawed, naming things like Harry Potter and Percy Jackson. Then it was my turn.

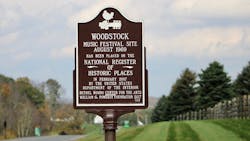

No hesitation: “Woodstock. Full four-hour director’s cut.”

If you haven’t seen it, you’re missing out on a simultaneous history lesson and classic rock show. The famous performances like Jimi Hendrix and Sly and the Family Stone are as good as you might have heard, but the real eye opener for me was the last band that appears before intermission: Ten Years After. They turn in an 11-minute original called “I’m Going Home” that starts fast, slows in the middle to weave blues and rock songs together from John Lee Hooker, Carl Perkins, and Jerry Lee Lewis before wrapping up with a fiery close.

Later that night, thinking about that sequence, it occurred to me that 2024 would be my 10th year at the helm of Plant Services. I started reflecting on all the changes in my life since mid-2014, and pretty quickly started thinking about the massive ways that our profession has changed in that time too.

IoT. COVID. ChatGPT. AI. Remote monitoring. The supply chain crisis. Motion amplification. Retirements. Reshoring. I could continue but you get the idea.

All of which has led to this month’s cover story, the first article in an occasional series on how the reliability and maintenance world has changed over the past 10 years. For this article, I was curious to find out if people in industry thought that the skill set of the average mechanical millwright had changed much, given how many new technologies have been developed this past decade to assess machine health.

Some respondents expanded the definition of “skill set” in meaningful ways, emphasizing that communication skills were now more important than ever, especially the ability to speak more than one language. Others observed that teams were now expected to synthesize a wide set of skills and technologies to make sense of the machine health data at their specific site.

The full interviews with each expert will be posted on www.plantservices.com. I think my favorite response though centered on those plants that do the right thing but for the wrong reasons, such as adopting advanced tools yet using them to do better reactive maintenance instead of proactive work.

It sounds like the way that famous concert took shape 55 years ago.

About the Author

Thomas Wilk

editor in chief

Thomas Wilk joined Plant Services as editor in chief in 2014. Previously, Wilk was content strategist / mobile media manager at Panduit. Prior to Panduit, Tom was lead editor for Battelle Memorial Institute's Environmental Restoration team, and taught business and technical writing at Ohio State University for eight years. Tom holds a BA from the University of Illinois and an MA from Ohio State University