Case Study: Advanced thermal camera with app-driven intelligence streamlines electrical testing workflows for Blackmon Power

Key Highlights

- App-driven thermal imaging slashes reporting time, helping contractors boost service efficiency and reduce labor costs.

- Real-time data capture improves inspection accuracy, cutting errors and enhancing electrical system reliability.

- Connected workflows enable field-to-office collaboration, streamlining maintenance decisions for critical facilities.

- Integrated thermal tools simplify training and close skills gaps, supporting safer, more consistent electrical testing.

Electrical contracting and testing companies play a vital role in assuring the safety and reliability of electrical systems and components. Industrial and commercial organizations lean on them to augment their internal provisioning and maintenance teams’ capabilities with deep electrical expertise and compulsory regulatory compliance.

To maximize efficiency and accuracy, these trusted third-party service providers routinely evaluate innovative opportunities to improve their tools and methods. One such development is a new app-powered thermal imaging camera for smarter asset monitoring and inspection reporting from the field, developed in partnership by Flir, a Teledyne Technologies company, and Condoit, an electrical software app developer.

Blackmon Power recently piloted the solution at a new “Forever On” data center campus for a major customer. The electrical and testing contractor succeeded in slashing its thermal inspection reporting times from 8-12 hours to less than five minutes, while also reducing risks and increasing transparency for the client.

Driving maintenance efficiency through digitized thermal inspection workflows

Blackmon Power specializes in independent electrical testing, arc flash studies, and commissioning support. Based in Charlotte, NC, the full-service electrical contracting and testing company helps to keep industrial, commercial, and mission-critical electrical distribution systems operating at optimal levels.

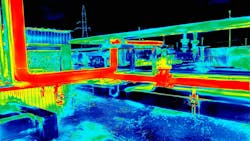

Its thermal imaging service detects, diagnoses, and recommends resolutions to heat-related electrical issues, enabling customers to proactively plan maintenance before a power outage or other emergency occurs.

Blackmon Power’s existing fleet of Flir handheld thermal cameras accurately captured high-quality images in the field, yet its technicians’ back-end reporting workflow needed improvement. At the time, they “spent days” manually transferring monitoring data from SD cards, entering notes in spreadsheets, and generating reports back at the office.

According to Tyler Grant, project manager for electrical testing, project engineering, and construction safety at Blackmon Power, a report for a small 10-15 component study would normally take around two hours, while a 250-300 component study report could require 8-12 hours. “For some jobs, reporting might consume 30% of the total time needed, which is a big hit to our bottom line,” he explains.

How Flir and Condoit integrated tools to modernize electrical testing operations

A new partnership between Flir and Condoit introduced an opportunity to replace traditional, time-consuming workflows with guided, connected, app-driven workflows, and Blackmon Power was among the first companies to benefit from it. The contractor actively invests in tools to improve efficiency and reduce costs, for themselves and their customers, to stay competitive.

The solution enables smart asset monitoring and in-field reporting. It couples any of the Flir iXX-Series of infrared thermal imaging cameras with smartphone-like functionality, including the i65, with the Condoit electrical data app, a digital platform built by electricians for electricians providing customer visibility, automatic single-line creation, and NFPA 70B-aligned maintenance.

The Condoit app supports immediate uploading, organization, and sharing of data with instant reporting and analysis, and eliminates time-consuming paperwork and manual transfer processes. Having the data and images captured on the app-driven i65 camera available in real time allows for real-time collaboration. By design, the combined solution enables faster and more reliable electrical service, increases safety and accuracy, reduces risks, and simplifies training.

Running the app on an iXX-Series camera provides the optimal user experience, making the entire inspection and reporting process more intuitive and seamless, though using another compatible Flir camera wirelessly connected to a smartphone running the app is also an option.

Pilot results: Faster reporting, higher accuracy, and reduced risks in electrical maintenance

Blackmon Power piloted the combined Flir i65 camera and Condoit app at T5 Data Centers’ new mission-critical data center campus in Kings Mountain, NC. Electrical distribution assets were scanned for temperature anomalies indicating issues such as loose connections and faulty equipment, and all data were automatically synchronized to the cloud. Using the new platform, Blackmon’s reporting times plunged and its service capabilities improved. The solution:

- Moved reporting from the office to the field

- Cut thermal inspection reporting times from 8-12 hours for a large job to fewer than five minutes

- Reduced the percentage of a technician’s time doing reporting to near zero with connected workflows

- Reduced errors to a bare minimum and made the report 10 times more accurate with real-time data entry

- Enabled real-time collaboration between field teams and office staff

- Bridged the thermography skills gap with intuitive, app-guided workflows

- Enhanced baseline data capture capabilities for customers who request it

- Provided for online customer portals, managed by Blackmon Power, where clients like T5 can centrally track electrical system health and better manage risks across their portfolio.

“The Flir i65/Condoit platform puts our team light years ahead of the competition,” says Grant. “It's cleaner, easier, and better for our customers, with great reporting on the back end. What’s more, with the i65 we don’t need a separate smartphone or digital camera.”

Scaling digital thermography to improve uptime and reliability across critical facilities

With app-driven thermal cameras designed to make inspections faster, easier, and more consistent, Blackmon Power raised its level of service excellence. “With the Flir i65 and Condoit app, our workflow is 100 times better than previously. Just from using it at T5, I can already tell it's going to help us move forward substantially,” says Grant.

Rob Milner, director global business development at Teledyne FLIR, agrees with that perspective. “Blackmon Power is delivering exactly what today’s clients demand: uncompromising equipment reliability, inspection reports that are simple to consume, and highly efficient contractor support,” he observes. “This integrated solution empowers them to respond faster, reduce complexity, and keep critical systems running without interruption.”

About the Author

Sheila Kennedy

CMRP

Sheila Kennedy, CMRP, is a professional freelance writer specializing in industrial and technical topics. She established Additive Communications in 2003 to serve software, technology, and service providers in industries such as manufacturing and utilities, and became a contributing editor and Technology Toolbox columnist for Plant Services in 2004. Prior to Additive Communications, she had 11 years of experience implementing industrial information systems. Kennedy earned her B.S. at Purdue University and her MBA at the University of Phoenix. She can be reached at [email protected] or www.linkedin.com/in/kennedysheila.