The multiple dimensions of digital transformation: Part 1

Over the past several years, industrial and other leaders have become increasingly interested in digital transformation.

This is not surprising, given that many potentially disruptive digital technologies have emerged in recent years, carrying with them the implied promise of significant change. Vendors have started to incorporate these technologies into their products and solutions, and use cases, best practices, and solutions are becoming more widely known and available. This adds pressure for organizations to “do something” about digitization. Unfortunately, it also tends to add to the confusion.

Clearly, this widespread digital transformation will continue to accelerate and evolve. It’s equally clear that every organization will need to innovate, change, and adapt. The question is, how can organizations take best advantage of this disruptive transformation?

Let’s consider the four dimensions that any industrial organization must consider when developing a digital transformation strategy: targets and outcomes, technologies, change and impacts, and management issues.

A holistic plan will work on all four dimensions, and changes in each dimension will affect the others.

Targets and outcomes

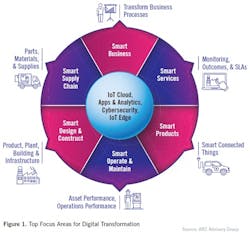

Digital transformation involves a host of interrelated things that need to be considered. It involves disruptive/transformational technologies, but it also affects how products are designed, sourced, manufactured, sold, delivered, and serviced. New business processes, value chains, management practices, information systems, and customer relationships will have to be cultivated, implemented, and optimized (see Figure 1).

ARC has identified six focus areas that are likely to be transformed for the better:

- Products

- Services

- Operations (both operate and maintain)

- Design and construct

- Supply chain

- Business processes

Smart products, or smart, connected “things,” are often the first thing that come to mind. These products typically have onboard sensors and embedded computational and communications capabilities. They can run analytics and other applications. Designing the smart product demands knowledge of these new capabilities as well as an understanding of how the products, ecosystem, and surrounding business models will operate. Who will own the product? Who will have access to the machine health data generated? How will it be operated and serviced? How will parts and supplies be sourced? What’s the expected lifetime? All may affect the design, materials, process, and production equipment, but they also have organizational implications.

New business models, service organizations, monitoring teams, pricing models, and financing and warranty support may be required. It may be worthwhile to finalize some of these before design commitments are made.

Many organizations will target production operations rather than products for their digital transformation plans. These organizations can choose to focus on asset performance (improving uptime and reducing risk to optimize the asset value over its lifecycle), operations performance (improving responsiveness, changeovers, throughput, quality, safety, sustainability, etc.), or both.

Other organizations will focus primarily on transforming their supply chains or service offerings (see Table 1). Innovations in service offerings could be based on enhanced connectivity and monitoring machine health data or could represent a new class of service offering centered around the customers’ use of the products. These digitally enabled services bring the company much closer to the customer while (ideally) improving the customer’s results.

Technologies

Because we live in an age in which so many emerging technologies have enormous disruptive potential, it would be easy to get too caught up in the technologies themselves. However, technology is an important dimension of digital transformation, so it’s worth highlighting some of the technologies that organizations should be considering.

Artificial intelligence, machine learning, cognitive computing

AI is the primary enabler and driving force behind digital transformation. With connectivity and execution, AI is already transforming industrial processes in operations, maintenance, engineering design, and supply chain. AI also powers a multitude of other transformative technologies that will drive industrial efficiency. Examples include augmented reality, autonomous machines, smart voice interface, and remote sensing.

Advanced materials

The materials used to make smart products are also becoming “smarter.” Materials science; advanced processing, forming and machining; and advanced digital modeling and design techniques all help increase the performance of the materials that make up all components in the value chain.

Modular/intensified manufacturing

Engineering science is progressing at a fast pace, assisted by digital modeling and engineering techniques. This enables new approaches for industrial production that will bring about a step change in performance and a profound transformation of industry.

At the same time, we’re seeing increased intensification – an engineering approach to miniaturize production equipment and improve heat and mass transfer characteristics. With increased modularization and intensification, production lines can be “lined up” instead of “scaled up” to attain the desired production levels.

The overall trend is toward highly sustainable, high-quality, high-precision, and highly flexible production that can adapt quickly to changing customer demands and economic circumstances.

Additive manufacturing

Additive manufacturing, perhaps the greatest disruptor in discrete manufacturing today, requires manufacturers to rethink a large swath of their manufacturing processes, methods, and techniques. Additive manufacturing could make decades of tribal knowledge based largely on traditional machining obsolete. In addition, industry is already learning how to “print” wear sensors directly into parts as they are made. This could radically change maintenance models by enabling these smart parts to order their own replacements when needed.

Augmented reality

While still in its infancy, immersive augmented reality (AR) will eventually become standard practice for maintenance and assembly operations. This technology will support and enhance work instructions, assembly/disassembly visualization, parts and tools identification, specifications, training, and more.

IoT platforms and solutions

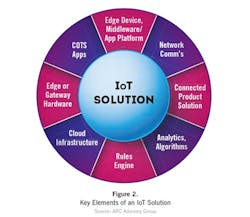

Many different varieties of IoT platforms and/or solutions undoubtedly will play a significant role for most companies on their respective digital transformation journeys. These platforms or solutions may include functionalities such as an application platform, network communications, support for connected products, analytics and algorithms, a rules engine, cloud infrastructure, edge or gateway hardware, and/or off-the-shelf apps (see Figure 2).

Edge connectivity

In many cases, digital transformation will require companies to build out the technology infrastructure located at or near operations to be able to efficiently collect, analyze, process, and store edge data. While operating at the edge can create unique security challenges, it also enables:

- Remote operations

- Reduced requirements for local IT skills

- The ability to run multiple applications at the edge, such as AI/analytics and field service

- Access to often-critical and time-sensitive locally generated data

- Autonomous operations

Blockchain

Greg Gorbach, VP of digitization and IoT at ARC Advisory Group, heads the analyst team responsible for research and consulting in transformative technologies. He also moderates the Digital Transformation Council, a collaborative user organization.

Valentijn de Leeuw, VP at ARC Advisory Group, focuses on organizational change and effectiveness, business process improvement, and value-based performance management. He has extensive experience in best management practices in process industries and serves as the focal point for ARC’s Benchmarking Consortium in Europe. He also acts as independent expert evaluator of research projects for the European Commission in the Information and Communication domains.

Blockchain decentralized database technology offers the potential to create a permanent, public, secure, transparent ledger system for tracking operations, components, and parts throughout manufacturing and across the supply chain. This will have applications for traceability, anti-counterfeiting, quality enforcement, product pedigree, carbon footprint, and more. In addition, expect to see blockchain technology used in commodity trading, production verification, and many other applications.

Robotics, autonomous machines

Smarter, safer robots will supplement and/or displace human workers in logistics, assembly, and other operations, freeing those humans for more value-adding activities. In addition, we are seeing telepresence robots, security robots, and other specialized robotics applications emerge.

Digital twin, digital thread

Products, production systems, buildings, and the like need to become smarter and more connected, which places new requirements on design systems. Smart, connected products need sensors, embedded hardware and software, network communications, and pedigree and must meet other system design and modeling requirements and constraints. Increasingly, this will utilize a “digital twin” or digital model of an asset with design specifications and engineering models that describe the asset’s geometry, materials, components and behavior, as well as a “digital thread” – a communication framework that allows a connected data flow and an integrated view of an asset’s data throughout its lifecycle.

Click here to read "The multiple dimensions of digital transformation: Part 2"